Abstract

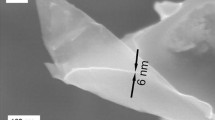

This study describes the combined effects of multi-walled carbon nanotubes (CNTs) additions and Y2O3 doping on the microstructures and mechanical properties of Al2O3-CNT nanocomposites fabricated by pressureless and hot-press sintering processes. A uniform dispersion of CNTs within the Al2O3 matrix was successfully attained via a combined approach using surfactant, sonication, and adequate period of incubation. Small amounts (1 wt.%) of Y2O3, as dopants, significantly affected the densification and properties of pressureless sintered monolithic Al2O3 and its nanocomposites at low CNT concentrations (<1 wt.%); however, they hardly showed any improvement at higher CNT contents. As opposed to the pressureless sintering, pressures applied during high temperature sintering in combination with the Y2O3 doping contributed in generating a homogenous microstructure and improved the densities (7 and 15%) and microhardness (11 and 12%) of Al2O3 reinforced with higher CNT contents (2 and 5 wt.%), respectively. Adding on, hot-pressed Y2O3-doped Al2O3 reinforced with 2 and 5 wt.% CNTs showed higher hardness (19 and 70%), flexural strength (10 and 5%), and fracture toughness (26 and 11%), respectively, compared to similar but CNT-free samples. These results showed that pressure-assisted sintering and Y2O3 are promising for the fabrication of CNT-reinforced Al2O3 nanocomposites, especially at higher CNT concentrations.

Similar content being viewed by others

References

E.T. Thostenson, Z. Ren, and T.W. Chao, Advances in the Science and Technology of Carbon Nanotubes and their Composites: A Review, Compos. Sci. Technol., 2001, 16, p 1899–1912

A. Peigney, C. Laurent, and A. Rousset, Carbon Nanotube Novel Ceramic Matrix Nanocomposites, Ceram. Int., 2000, 26, p 677–683

L. Osayande and I. Okoli, Fracture Toughness Enhancement for Alumina System: A Review, Int. J. Appl. Ceram. Technol., 2008, 5, p 313–323

N.P. Padture, Multifunctional Composites of Ceramics and Single-Walled Carbon Nanotubes, Adv. Mater., 2009, 21, p 1767–1770

J. Fan, D. Zhao, and J. Song, Preparation and Microstructure of Multi-Walled Carbon Nanotubes Toughened Al2O3 Composite, J. Am. Ceram. Soc., 2006, 89, p 750–753

G. Zhan, J. Kuntz, J. Wan, and K. Mukherjee, Single-Walled Carbon Nanotubes as Attractive Toughing Agent in Alumina Based Nanocomposites, Nat. Mater., 2003, 2, p 38–42

I. Ahmad, A. Kennedy, and Y.Q. Zhu, Multi-Walled Carbon Nanotubes Reinforced Al2O3 Nanocomposites: Mechanical Properties and Interfacial Investigations, Compos. Sci. Technol., 2010, 70, p 1199–1206

F. Inam, T. Pijis, and M.J. Reece, The Production of Advanced Fine-Grained Alumina by Carbon Nanotubes Addition, J. Eur. Ceram. Soc., 2011, 31, p 2853–2859

I. Ahmad, H. Cao, H. Chen, H. Zhao, A. Kennedy, and Y.Q. Zhu, Carbon Nanotube Toughened Aluminium Oxide Nanocomposites, J. Eur. Ceram. Soc., 2009, 30, p 865–873

F. Inam and M.J. Reece, Electrically Conductive Alumina-Carbon Nanotubes Prepared by Spark Plasma Sintering, J. Eur. Ceram. Soc., 2010, 30, p 153–157

J. Sun and L. Gao, Development of a Dispersion Process for Carbon Nanotubes in Ceramic Matrix by Hetero-Coagulation, Carbon, 2003, 41, p 1063–1068

B. Chan and I. Seung, Fabrication of CNT-Reinforced Al2O3 Matrix Nanocomposites by Sol-Gel, Mater. Sci. Eng., 2005, 395, p 124–128

C.S. Zhang, W.G. Fahrenholtz, G.E. Hilmas, and J.Y. Edward, Pressureless Sintering of Carbon Nanotube—Al2O3 Composites, J. Eur. Ceram. Soc., 2010, 30(6), p 1373–1380

J. Wang, S.Y. Lim, and C.H. Chew, Dramatic Effect of a Small Amount of MgO Addition on the Sintering of Al2O3—5 vol.% SiC Nanocomposite, Mater. Lett., 1998, 33, p 273–277

Y.K. Jeong, A. Nakahira, and K. Niihara, Effects of Additives on Microstructure and Properties of Al2O3—Silicon Carbide Nanocomposites, J. Am. Ceram. Soc., 1999, 82, p 3609–3612

D.A. Rani, Y. Yoshizawa, K. Hirao, and Y. Yamushi, Effect of Rare-Earth Dopants on Mechanical Properties of Al2O3, J. Am. Ceram. Soc., 2008, 87, p 289–292

F. Jianxin, A.M. Thompson, M.P. Harmer, and H.M. Chan, Effect of Yttrium and Lanthanum on the Final-Stage Sintering Behavior of Ultrahigh-Purity Al2O3, J. Am. Ceram. Soc., 1997, 80, p 2005–2012

S. Lartigue, C. Carry, and L. Priester, Grain Boundaries in High Temperature Deformation of Yttria and Magnesia Co-Doped Alumina, J. Phys. Colloq., 1990, 51, p 985–990

D. Delaunay, A.M. Huntz, and P. Lacombe, The Influence of Yttrium on the Sintering of Al2O3, J. Less Common Met., 1980, 70, p 115–117

Y.K. Jeong, A. Nakharia, and K. Niihara, Effect of Additives on Microstructure and Properties of Al2O3 Silicon Carbide Nanocomposite, J. Am. Ceram. Soc., 1999, 82, p 3069–3612

S.K.C. Pillai and S. Hamsphire, Controlling the Grain Growth in Yttria Doped Al2O3—5 wt.% SiC Nanocomposite Prepared by Pressureless Sintering, J. Am. Ceram. Soc., 2004, 24, p 3317–3326

A.G. Robertson, D.S. Wilkinson, and C.H. Caceres, Creep and Creep Fracture in Hot-Pressed Al2O3, J. Am. Ceram. Soc., 1991, 74, p 915–921

S. Lartigue and F. Dupau, Grain Boundary Behavior in Superplastic Mg-Doped Al2O3 with Yttria Co-doping, Acta. Metal. Mater., 1994, 42, p 293–302

F. Cesari, L. Esposito, F.M. Furgiuele, C. Maletta, and A. Tucci, Fracture Toughness of Al2O3-zirconia composites, Ceram. Int., 2006, 32, p 249–255

M. Ajayan, Nanotubes from Carbon, Chem. Rev., 1999, 99, p 1787–1799

T.K. Shen and P. Hing, Ultrasonic Through-Transmission Method of Evaluating the Modulus of Elasticity of Al2O3-ZrO2 Composite, J. Mater. Sci., 1997, 32, p 6633–6638

G.R. Anstis, P. Chantikul, and D.B. Marshall, A Critical Evaluation of Indentation Technique for Measuring Fracture Toughness: I, Direct Crack Method, J. Am. Ceram. Soc., 1986, 4(1), p 533–538

J. Sun and L. Gao, Reinforcement of Al2O3 Matrix with Multi-Walled CNTs, Ceram. Int., 2005, 31, p 893–896

C.E. Borsa, H.S. Ferreira, and R.A. Kiminami, Liquid Phase Sintering of Al2O3/SiC, J. Eur. Ceram. Soc., 1999, 19, p 615–621

M. Alex, I. Todd, and S.G. Robert, Effects of Yttrium on the Sintering and Microstructure of Al2O3 Silicon Carbide Nanocomposites, J. Am. Ceram. Soc., 2005, 88(9), p 2354–2361

C.P.S. Kumar, B. Baron, and S. Hampshire, Effect of Dopants on Densification, Microstructure and Mechanical Properties of Al2O3-Silicon Nanocomposites Ceramics Prepared by Pressureless Sintering, J. Eur. Ceram. Soc., 2004, 24, p 3317–3326

J.D. Cawley and J.W. Halloran, Dopant Distribution in Nominally Yttrium-Doped Sapphire, J. Am. Ceram. Soc., 1986, 69, p 195–196

F. Danan, L.Q. Chen, and S.P. Chen, Numerical Simulation of Zener Pinning with Growing Second-Phase Particles, J. Am. Ceram. Soc., 1998, 81, p 526–532

R.L. Coble, Diffusion Models for Hot Pressing with Surface Energy and Pressure Effects as Driving Forces, J. Appl. Phys., 1970, 41, p 4798–4808

S. Sarkar and P.K. Das, Microstructure and Physicomechanical Properties of Pressure-Less Sintered Multi-Walled Carbon Nanotube/Alumina Nanocomposites, Ceram. Int., 2012, 38, p 423–432

O. Thomas and J. Rodel, Evolution of Mechanical Properties of Porous Al2O3 During Free Sintering and Hot Pressing, J. Am. Ceram. Soc., 1999, 82, p 3080–3086

M.S. Lee, Handbook of Composites Reinforcements, Wiley-Blackwell, New York, 1992, p 151

M. Chen, F.R. Jones, and J.E. Bailey, The Role of Interface on the Densification of Sol-Gel Processed Al2O3 and Mullite Fibre Composites, Inst. Phys. Conf. Ser., 1990, 111, p 227–237

K.M. Liew, C.H. Wong, X.Q. He, and M.J. Tan, Thermal Stability of Single and Multi-Walled Carbon Nanotubes, Phys. Rev., 2005, B71, p 075424

Z. Xia, W.A. Curtain, and B.W. Sheldon, Fracture Toughness of Highly Ordered Carbon Nanotubes/Al2O3 Nanocomposite, Trans. ASME, 2004, 126, p 224–238

C. Laurent, A. Peigney, and A. Rousset, Carbon Nanotubes-Fe-Al2O3 Nanocomposites. Part II: Microstructure and Mechanical Properties of the Hot-Pressed Composites, J. Eur. Ceram. Soc., 1998, 18, p 2005–2013

Acknowledgments

IA appreciates the financial support from the Center of Excellence for Research in Engineering Materials (CEREM), Advanced Manufacturing Institute (AMI), King Saud University (KSU), and Kingdom of Saudi Arabia. Authors are grateful to all the technical staff of CEREM laboratories for their kind assistance in material characterization. The first author is very thankful to Prof. Yanqiu Zhu of Exeter University, United Kingdom for his kind contribution in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmad, I., Dar, M.A. Structure and Properties of Y2O3-Doped Al2O3-MWCNT Nanocomposites Prepared by Pressureless Sintering and Hot-Pressing. J. of Materi Eng and Perform 23, 2110–2119 (2014). https://doi.org/10.1007/s11665-014-0975-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0975-y