Abstract

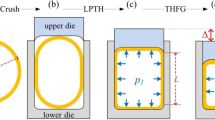

Loading path plays a dominant role in tube hydroforming (THF), and the pulsating loading path has been reported capable of improving the formability of a tube in hydrobulging with axial feeding. As a new THF process, the tube hydroforming with radial crushing (THFRC) is receiving increasing attention; however, knowledge on the process still remains insufficient to extend its application to various other fields. In this study, the experiments of THFRC under both the pulsating and the linear hydraulic pressures were carried out to investigate the deformation behavior. The influences of the amplitude and the frequency of the pulsating hydraulic pressure on the shape precision, wall thickness, and the microstructures of the deformed parts were analyzed. Subsequently, metallographic examinations of the deformed specimens were conducted in an attempt to clarify the relationship between the microstructural evolution and deformation behavior. The mechanism of formability improvement in THFRC by the pulsating hydraulic pressure was explored from the perspective of microstructure. Compared with the linear hydraulic pressure, the pulsating hydraulic pressure could generate a higher shape precision, a more uniform wall thickness, as well as less martensites, and larger grain. The microstructural evolution induced by the pulsating loading path is supposed to contribute to the formability improvement of SUS304 stainless steel tubes.

Similar content being viewed by others

References

Y. Aueulan, G. Ngaile, and T. Altan, Optimizing tube Hydroforming Using Process Simulation and Experimental Verification, J. Mater. Process. Technol., 2004, 146(1), p 137–143

F. Mohammadi and M.M. Mashadi, Determination of the Loading Path for Tube Hydroforming Process of a Copper Joint Using a Fuzzy Controller, Int. J. Adv. Manuf. Technol., 2009, 43(1-2), p 1–10

X. Elie-dit-cosaque, M.S. Chebbah, H. Naceur, and A. Gakwaya, Analysis and Design of Hydroformed Thin-Walled Tubes Using Enhanced One-Step Method, Int. J. Adv. Manuf. Technol., 2012, 59(5-8), p 507–520

G. Morphy, Pressure-Sequence and High-Pressure Hydro-Forming, Tube Pipe J., 1998, 2(1), p 128–135

S. Li, X. He, W. Zhang, and Z. Lin, Study on the Crushing and Hydro-Forming Processes of Tubes in a Trapezoid–Sectional Die, Int. J. Adv. Manuf. Technol., 2009, 43(1-2), p 67–77

P. Lei, L. Yang, and Y. Zhang, Investigation on the Formability of Tube in Hydroforming with Radical Crushing under Simple Loading, Adv. Mater. Res., 2011, 291-294, p 595–600

L. Yang, P. Lei, and C. Guo, The Influence of Friction on Forming Accuracy of Tubular Parts by Hydroforming with Radial Crushing, Int. J. Adv. Mater. Res., 2011, 328-330, p 1386–1390

T. Rikimaru and M. Ito, Hammering Hydro-Forming of Tubes, Press Work., 2001, 39(1), p 58–65

T. Hama, M. Asakawa, H. Fukiharu, and A. Makinouchi, Simulation of Hammering Hydro-Forming by Static Explicit FEM, J. Tubehydro, 2004, 2003, p 80–83

K. Mori, A.U. Patwari, and S. Maki, Improvement of Formability by Oscillation of Internal Pressure in Pulsating Hydro-Forming of Tube, CIRP Ann. Manuf. Technol., 2004, 53(1), p 215–218

L. Yang and F. Chen, Investigation on the Formability of Tube in Pulsating Hydro-Forming, J. Mater. Sci. Forum, 2009, 142(1), p 628–629

S. Zhang, A. Yuan, B. Wang, H. Zhang, and Z. Wang, Influence of Loading Path on Formability of 304 Stainless Steel Tubes, Sci. China, 2009, 52(8), p 2263–2268

Y. Lianfa and G. Cheng, Determination of Stress-Strain Relationship of Tubular Material with Hydraulic Bulge Test, Thin Walled Struct., 2008, 46, p 147–154

M. Milad, N. Zreiba, and F. Elhalouani, The Effect of Cold Work on Structure and Properties of AISI, 304 Stainless Steel, J. Mater. Process. Technol., 2008, 203, p 80

A.K. Jha, D. Sivakumar, K. Sreekumar, and M.C. Mittal, Role of Transformed Martensite in the Cracking of Stainless Steel Plumbing Lines, Eng. Fail. Anal, 2008, 15(8), p 1042–1051

G. Hu, C. Xu, and J. Yuan, Deformation Induced Martensite Transformation and its Magnetic Memory Effect of Austenitic 304 Stainless Steel, Nondestruct. Test., 2008, 30(4), p 216-219 (in Chinese)

D. Chen, X. Wen, X. Li, and Z. Zhu, Martensitic transformation (1), Heat Treat. Technol. Equip., 2011, 32, p 60–66 (in Chinese)

R. Fu, Y. Su, P. Ye, X. Wei, L. Li, and J. Zhang, Internal Fiction on the Bake-Hardening Behavior of 0.11C-1.67Mn-1.19Si TRIP Steel, J. Mater. Sci. Technol., 2009, 25(1), p 141–144

D.R. Culp and H.T. Gencsoy, Metal Deformation with Ultrasound, Ultrason. Symp., 1973, 16, p 195–198

B. Langenecker, Effect of Ultrasound on Deformation Characteristics of Metal, IEEE Trans. Sonics Ultrason., 1966, 13, p 1–8

Acknowledgments

The authors gratefully acknowledge the supports of the National Natural Science Foundation of China (Grant number 51065006&51271062), Guangxi Natural Science Foundation (Grant number 2013GXNSFAA019305), and Guangxi Key Laboratory of Manufacturing System & Advanced Manufacturing Technology (Grant number 11-031-12_006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Rong, H. & He, Y. Deformation Behavior of a Thin-Walled Tube in Hydroforming with Radial Crushing Under Pulsating Hydraulic Pressure. J. of Materi Eng and Perform 23, 429–438 (2014). https://doi.org/10.1007/s11665-013-0783-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0783-9