Abstract

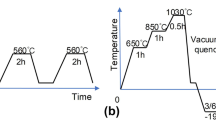

As a low-carbon alloy steel, 20Cr2Ni4A steel has an excellent mechanical properties. It has been used for producing heavy-duty gears, which require good wear and fatigue resistance. The vacuum carburizing process can improve the quality of gears and extend the service life. In this article, a complete heat-treatment process for 20Cr2Ni4A, with carburizing, tempering, quenching and cryogenic steps involved, was proposed. A numerical method was employed to design the carburizing step. The carburized samples were characterized by analysis of carbon profile, surface-retained austenite content, microstructure, and hardness profile. A good microstructure was obtained with acicular-tempered martensite, less-retained austenite, fine granular-dispersed carbides, and was oxide free. The final surface hardness was 64.2HRC, and the case depth was 0.86 mm, which meet the requirements of products. The relationships among process, performance, and microstructure were investigated to understand the inner connection.

Similar content being viewed by others

References

J.R. Davis, Surface Hardening of Steels, ASM, Materials Park, OH, 2002

O. Karabelchtchikova, “Fundamentals of Mass Transfer in Gas Carburizing,” Worcester Polytechnic Institute, 2007

W.L. Grube and J.G. Gay, High-Rate Carburizing in a Glow-Discharge Methane Plasma, Metall. Trans. A, 1978, 9(10), p 1421–1429

T. Noda, M. Okabe, and S. Isobe, Hard Surfacing of TiAl Intermetallic Compound by Plasma Carburization, Mater. Sci. Eng., A, 1996, 213(1), p 157–161

C.J. Scheuer, R.P. Cardoso, R. Pereira et al., Low Temperature Plasma Carburizing of Martensitic Stainless Steel, Mater. Sci. Eng., A, 2012, 539, p 369–372

Z. Fayi, C. Chenghong, M. Qingchang, et al., Observation and Analysis of the Microstructure in Carburized Surface Layer of Steel 20Cr2Ni4A Treated with Conventional and Rare Earth Carburizing Processes, J. Rare Earth, 1996, 02

F.S. Chen and L.D. Liu, Deep-Hole Carburization in a Vacuum Furnace by Forced-Convection Gas Flow Method, Mater. Chem. Phys., 2003, 82(3), p 801–807

C. Dawes and D.F. Tranter, Production Gas Carburizing Control, Heat Treat. Met., 2004, 31(4), p 99–108

V.A. Munts and A.P. Baskatov, Rate of Carburizing of Steel, Met. Sci. Heat Treat., 1980, 22(5-6), p 358–360

G.G. Tibbetts, Diffusivity of Carbon in Iron and Steels at High Temperatures, J. Appl. Phys., 1980, 51(9), p 4813–4816

J.I. Goldstein and A.E. Moren, Diffusion Modeling of the Carburization Process, Metall. Mater. Trans. A, 1978, 9(11), p 1515–1525

A. Ruck, D. Monceau, and H.J. Grabke, Effects of Tramp Elements Cu, P, Pb, Sb and Sn on the Kinetics of Carburization of Case Hardening Steels, Steel Res., 1996, 67(6), p 240–246

J. Mackerle, Finite Element Analysis and Simulation of Quenching and Other Heat Treatment Processes, A Bibliography (1976-2001), Comput. Mater. Sci., 2003, 27, p 313–332

P. Cavaliere, G. Zavarise, and M. Perillo, Modeling of the Carburizing and Nitriding Processes, Comput. Mater. Sci., 2009, 46, p 26–35

D.-W. Kim, Y.-G. Cho et al., A Numerical Model for Vacuum Carburization of an Automotive, Met. Mater. Int., 2011, 17(6), p 885–890

G. Wang and R.D. Sisson, Development of Simulation Tool for Prediction and Optimization on Carburizing Processes, Heat Treating Proceedings of the 25th ASM Heat Treating SOCIETY Conference, 2009, p 91–95

Y. Mei, L. Zhang, and R.D. Sisson, Modeling of Carbon Concentration Profile Development During Both Atmosphere and Low Pressure Carburizing Processes, J. Mater. Eng. Perform., 2012, 22(7), p 1–6

F. Neumann and B. Person, Beitrag zur Metallurgie der Gasaufkohlung Zusammen-hang zwischen dem Kohlenstoffpotential der Gasphase und des Werkstückes unter Berücksichtigung der Legierungselemente, Härterei-Technische Mitteilungen, 1968, 23, p 296

Acknowledgements

This work was financially supported by the National Basic Research Program of China (973 Program) (No. 2011CB013404) and National Science and Technology Major Project of the Ministry of Science and Technology of China (No. 2012ZX04012011). The authors are grateful to Mr. Jingchen Lu, Mr. Zijiang Xu and Mr. Peng Zhou from ASIMCO Tianwei Fuel Injection Equipment Stock Co. Ltd. for facility support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, S., Wang, G., Zhao, X. et al. Experimental Study on Vacuum Carburizing Process for Low-Carbon Alloy Steel. J. of Materi Eng and Perform 23, 545–550 (2014). https://doi.org/10.1007/s11665-013-0762-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0762-1