Abstract

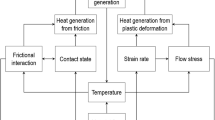

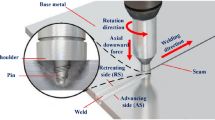

It is still not clearly known as to what extent the temperature field of friction stir welding joint is influenced by backplate diffusivity owing to the limitation of temperature measuring points. In the present study, therefore, the effect of backplate diffusivity on the temperature field of the workpiece was systematically investigated based on the numerical analysis. Simulated results show that the backplate diffusivity has a significant influence on not only the peak temperature but the final temperature distribution. More heat is dissipated by using a high thermal conductivity backplate during FSW. With increasing the backplate diffusivity, the peak temperature decreases gradually and the average cooling rate increases first and then slightly decreases. In addition, the time spent above 195 °C presents a nearly linear decrease with increasing the backplate diffusivity. Moreover, the width of temperature region higher than 195 °C in the transverse direction is remarkably diminished by using the backplate of a high conductivity, and changes little during the entire process.

Similar content being viewed by others

References

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1–78

R. Nandan, T. DebRoy, and H.K.D.H. Bhadeshia, Recent Advances in Friction-Stir Welding-Process, Weldment Structure and Properties, Prog. Mater. Sci., 2008, 53, p 980–1023

A. Simar, Y. Bréchet, B. de Meester, A. Denquin, C. Gallais, and T. Pardoen, Integrated Modeling of Friction Stir Welding of 6xxx Series Al Alloys: Process, Microstructure and Properties, Prog. Mater. Sci., 2012, 57, p 95–183

H. Aydın, A. Bayram, A. Uğuz, and S.K. Akay, Tensile Properties of Friction Stir Welded Joints of 2024 Aluminum Alloys In Different Heat-Treated State, Mater. Design, 2009, 30(6), p 2211–2221

H.J. Liu, H. Fujii, M. Maeda, and K. Nogi, Tensile Properties and Fracture Locations of Friction-Stir-Welded Joints of 2017-T351 Aluminum Alloy, J. Mater. Process. Technol., 2003, 142(3), p 692–696

W.B. Lee, Y.M. Yeon, and S.B. Jung, The Improvement of Mechanical Properties of Friction-Stir-Welded A356 Al Alloy, Mater. Sci. Eng. A, 2003, 355(1–2), p 154–159

K. Elangovan and V. Balaubramanian, Influence of Post-weld Heat Treatment on Tensile Properties of Friction Stir Welded AA6061 Aluminum Alloys Joints, Mater. Charact., 2008, 59(9), p 1168–1177

A. Scialpi, L.A.C. De Filippis, and P. Cavaliere, Influence of Shoulder Geometry on Microstructure and Mechanical Properties of Friction Stir Welded 6082 Aluminium Alloy, Mater. Des., 2007, 28(4), p 1124–1129

C. Genevois, A. Deschamps, A. Denquin, and B. Doisneau-coottignies, Quantitative Investigation of Precipitation and Mechanical Behaviour for AA2024 Friction Stir Welds, Acta Mater., 2005, 53, p 2447–2458

P. Upadhyay and A.P. Reynolds, Effects of Thermal Boundary Conditions in Friction Stir Welded AA7050-T7 Sheets, Mater. Sci. Eng. A, 2010, 527(6), p 1537–1543

R.D. Fu, Z.Q. Sun, R.C. Sun, Y. Li, H.J. Liu, and L. Lei, Improvement of Weld Temperature Distribution and Mechanical Properties of 7050 Aluminum Alloy Butt Joints by Submerged Friction Stir Welding, Mater. Des., 2011, 32(10), p 4825–4831

R. Zettler, S. Da, A.M. Antonio, S. Rodrigues, A. Blanco, S. Dos, and F. Jorge, Dissimilar Al to Mg Alloy Friction Stir Welds, Adv. Eng. Mater., 2006, 8(5), p 415–421

Y.S. Sato, S.H.C. Park, M. Michiuchi, and H. Kokawa, Friction Stir Welding of Ultrafine Grained Al Alloy 1100 Produced by Accumulative Roll-bonding, Scr. Mater., 2004, 50(1), p 57–60

I. Galvão, J.C. Oliveira, A. Loureiro, and D.M. Rodrigues, Formation and Distribution of Brittle Structures in Friction Stir Welding of Aluminium and Copper: Influence of Shoulder Geometry, Intermetallics, 2012, 22, p 122–128

H.J. Liu, J.J. Shen, L. Zhou, Y.Q. Zhao, C. Liu, and L.Y. Kuang, Microstructural Characterisation and Mechanical Properties of Friction Stir Welded Joints of Aluminium Alloy to Copper, Sci. Technol. Weld. Join., 2011, 16(1), p 92–98

J. Ouyang, E. Yarrapareddy, and R. Kovacevic, Microstructural Evolution in the Friction Stir Welded 6061 Aluminum Alloy (T6-Temper Condition) to Copper, J. Mater. Process. Technol., 2006, 172(1), p 110–112

C.Y. Chen, H.J. Liu, and J.C. Feng, Stability of the Grain Structure in 2219-O Aluminum Alloy Friction Stir Welds During Solution Treatment, Mater. Charact., 2007, 58(2), p 174–178

M.A. Mofid, A. Abdollah-zadeh, and F.M. Ghaini, The Effect of Water Cooling during Dissimilar Friction Stir Welding of Al Alloy to Mg Alloy, Mater. Des., 2012, 36, p 161–167

W.Y. Li, Z.H. Zhang, J.L. Li, and Y.J. Chao, Numerical Analysis of Joint Temperature Evolution during Friction Stir Welding Based on Sticking Contact, J. Mater. Eng. Perform., 2012, 21(9), p 1849–1856

W.F. Xu, J.H. Liu, D.L. Chen, G.H. Luan, and J.S. Yao, Change of Microstructure and Cyclic Deformation Behavior Along the Thickness in a Friction-Stir-Welded Aluminum Alloy, Scr. Mater., 2012, 66(1), p 5–8

T. Ogura, Y. Saito, T. Nishida, H. Nishida, T. Yoshida, N. Omichi, M. Fujimoto, and A. Hirose, Partitioning Evaluation of Mechanical Properties and the Interfacial Microstructure in a Friction Stir Welded Aluminum Alloy/Stainless Steel Lap Joint, Scr. Mater., 2012, 66(8), p 531–534

W.F. Xu, J.H. Liu, G.H. Luan, and C.L. Dong, Temperature Evolution, Microstructure and Mechanical Properties of Friction Stir Welded Thick 2219-O Aluminum Alloy Joints, Mater. Des., 2009, 30(6), p 1886–1893

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (51005180, 51275338), the Fok Ying-Tong Education Foundation for Young Teachers in the Higher Education Institutions of China (131052), the Research Fund of the State Key Laboratory of Solidification Processing (NPU, China) (69-QP-2011), the Fundamental Research Fund of NPU (JC201233) and the 111 Project (B08040) for their financial supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Li, W., Li, J. et al. Numerical Analysis of Effect of Backplate Diffusivity on the Transient Temperature in Friction Stir Welding. J. of Materi Eng and Perform 22, 2446–2450 (2013). https://doi.org/10.1007/s11665-013-0538-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0538-7