Abstract

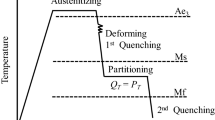

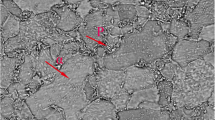

Hot stamping is an innovative operation in metal-forming processes which virtually avoids the cracking and wrinkling of high strength steel (HSS) sheets. Examining the phase transformation and mechanical properties of HSS by means of experiments is challenging. In this article, a numerical model of the hot stamping process including forming, quenching, and air cooling was developed to reveal the microstructure evolution and to predict the final mechanical properties of hot-stamped components after multi-process cycles. The effects of the number of process cycles and the holding times on the temperature of HSS were examined using the model. The microstructure evolution of HSS under variable holding times is illustrated. The mechanical properties, particularly hardness and tensile strength, were predicted. It was found that the martensitic content increased with increasing holding time, and the martensitic content of the formed component at the flange and end was higher than for the sidewall, and lowest for the bottom. The hardness trend was consistent with the martensitic content. After six process cycles, the predictive errors of the model for hardness and tensile strength were acceptable for practical applications in engineering. Comparison between the predicted results and the experiment results showed that the developed model was reliable.

Similar content being viewed by others

References

A. Andersson, Numerical and Experimental Evaluation of Springback in Advanced High Strength Steel, J. Mater. Eng. Perform., 2007, 16, p 301–307

M. Naderi, V. Uthaisangsuk, U. Prahl, and W. Bleck, A Numerical and Experimental Investigation into Hot Stamping of Boron Alloyed Heat Treated Steels, Steel Res. Int., 2008, 79(2), p 77–79

A. Yanagida, T. Kurihara, and A. Azushima, Development of Tribo-simulator for Hot Stamping, J. Mater. Process. Technol., 2010, 210, p 456–460

T. Altan, Hot-Stamping Boron-Alloyed Steels for Automotive Parts, Part I: Process Methods and Uses, Stamp. J., 2006, 40, p 1–2

K. Mori and Y. Okuda, Tailor Die Quenching in Hot Stamping for Producing Ultra-High Strength Steel Formed Parts Having Strength Distribution, CIRP Ann. Manuf. Technol., 2010, 59, p 291–294

K. Kusumi, S. Yamamoto, T. Takeshita, and M. Abe, The Effect of Martensite Transformation on Shape Fixability in the Hot Stamping Process, Steel Res. Int., 2008, 79, p 71–76

P.F. Bariani, S. Bruschi, A. Ghiotti, and A. Turetta, Testing Formability in the Hot Stamping of HSS, CIRP Ann. Manuf. Technol., 2008, 57(1), p 265–268

M.-G. Lee, S.-J. Kim, and H.N. Han, Finite Element Investigations for the Role of Transformation Plasticity on Springback in Hot Stamping Process, Comput. Mater. Sci., 2009, 47, p 556–567

P. Åkerström and M. Oldenburg, Austenite Decomposition During Press Hardening of a Boron Steel—Computer Simulation and Test, J. Mater. Process. Technol., 2006, 174, p 399–406

H.-H. Bok, M.-G. Lee, E.J. Pavlina, F. Barlat, and H.-D. Kim, Comparative Study of the Prediction of Microstructure and Mechanical Properties for a Hot-Stamped B-Pillar Reinforcing Part, Int. J. Mech. Sci., 2011, 53, p 744–752

Li Wang, X-f Yang, and J-x Lu, Development of High Strength Steel Blanks for Lightweight Automobile, Iron Steel, 2006, 41, p 5–7

D-l Song and S-h Jiao, Validation of Hardness Prediction Mathematic Models, Mater. Mech. Eng., 2008, 32(3), p 29–31

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210, p 2103–2118

M. Eriksson, M. Oldenburg, M.C. Somani, and L.P. Karjalainen, Testing and Evaluation of Material Data for Analysis of Forming and Hardening of Boron Steel Components, Modell. Simul. Mater. Sci. Eng., 2002, 10, p 1–18

J. Bao, H.-s. Liu, Z.H.-w. Xing, B.-y. Song, and Y.-y. Yang, Flow Behavior of Boron Steel for Hot Stamping at Elevated Temperature, Mater. Sci. Technol., 2010, 18(1), p 48–51

H.-s. Liu, W. Liu, J. Bao, and Z.H.-w. Xing, Numerical and Experimental Investigation into Hot Forming of Ultra High Strength Steel Sheet, J. Mater. Eng. Perform., 2011, 20(1), p 1–10

I.T. Shvets, Contact Heat Transfer Between Plane Metal Surfaces, Int. Chem. Eng., 1964, 4(4), p 621

D. Pitts and L. Sissom, Schaum’s Outline of Theory and Problems of Heat Transfer, 2nd ed., McGraw-Hill, New York, 1998, p 194–197

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, J., Lei, C., Xing, Z. et al. Predictions of the Mechanical Properties and Microstructure Evolution of High Strength Steel in Hot Stamping. J. of Materi Eng and Perform 21, 2244–2254 (2012). https://doi.org/10.1007/s11665-012-0180-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0180-9