Abstract

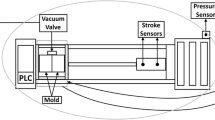

High-pressure die casting is the preferred process for manufacturing Mg-alloy components used for numerous applications. High-pressure die casting is suitable for mass production and has the advantage of also being suitable for accurately fashioning objects of complicated shapes. One disadvantage of high-speed die casting is the occurrence of defects such as shrinkage or air entrainment. Gating system design must be very effective in actual manufacturing facilities to avoid the occurrence of such defects. The objective of this study is to present a methodology for obtaining optimal designs of 4-cavity thin electronic component housings. The fluid behavior and amount of air entrainment caused by the overflows and air vent designs were analyzed using a computer fluid dynamics (CFD) simulator. The effectiveness of the proposed system was demonstrated through CFD simulations and experiments using an actual manufacturing process. Also, the effect of vacuum systems on the porosity and mechanical properties of the castings was studied. The volume of porosity in the casting was found to be significantly reduced using vacuum assistance during die casting. As a result, the tensile strength and the elongation of the die casting products are improved.

Similar content being viewed by others

References

S.K. Kim, J.K. Lee, Y.O. Yoon, and H.H. Jo, Development of AZ31 Mg Alloy Wrought Process Route, Without Protective Gas, J. Mater. Process. Technol., 2007, 187–188, p 757–760

B.S. Shin, Y. Kim, and D.H. Bae, Deformation Behavior of a Wrought Mg-Zn-RE Alloy at the Elevated Temperatures, J. Korean Inst. Met. & Mater., 2008, 46, p 1–5

A. Luo, J. Renaud, I. Nakatsugawa, and J. Plourde, Magnesium Castings for Automotive Applications, J Manag, 1995, 47, p 28–31

D.M. Magers, Light Materials for Transportation Systems, Vol 53, Center for Advanced Aerospace Materials POSTECH, Pohang, 1993

O. Lunder, T.Kr. Aune, and K. Nisanciogtu, Effect of Mn Additions on the Corrosion Behaviour of Mould-Cast Magnesium ASTM AZ91, Corrosion, 1987, 43, p 291

S.Y. Chang, D.H. Lee, B.S. Kim, T.S. Kim, Y.S. Song, S.H. Kim, and C.B. Lee, Characteristics of Plasma Electrolytic Oxide Coatings on Mg-Al-Zn Alloy Prepared by Powder Metallurgy, Met. Mater. Inst., 2009, 15, p 759–764

B.S. Shin, J.W. Kwon, and D.H. Bae, Microstructure and Deformation Behavior of a Mg-RE-Zn-Al Alloy Reinforced with the Network of a Mg-RE Phase, Met. Mater. Inst., 2009, 15, p 203–207

S.H. Choi, D.H. Kim, and B.S. Seong, Simulation of Strain-Softening Behaviors in an AZ31 Mg Alloy Showing Distinct Twin-Induced Reorientation Before a Peak, Met. Mater. Inst., 2009, 15, p 239–248

E.A. Herman, Die Casting Dies: Design, North American Die-casting Association, 1992, p 15–24.

J.R. Brevick, Die Casting Defects Causing Rejections During Machining, Die Cast. Eng., 1997, 5, p 42–46

C.M. Gourlay, H.I. Laukli, and A.K. Dahle, Defect Band Characteristics in Mg-Al, Al-Si High-Pressure Die Castings, Metall. Mater. Trans. A, 2007, 38A, p 1833–1844

S.G. Lee and A.m. Gokhale, Formation of Gas Induced Shrinkage Porosity in Mg-Alloy High-Pressure Die Castings, Scripta Mater., 2006, 55(4), p 387–390

M. Mclaughlin, C.W. Kim, and A. Conrad, Flow Pattern in the Casting Process, Mater. Des., 2004, 25, p 655–661

A. Kimatsuka, I. Ohnaka, J.D. Zhu, and T. Kamitsu, Mold Filling Simulation with Consideration of Gas Escape Through Sand Mold, Int. J. Cast. Met. Res., 2002, 15(3), p 149–152

A. Kimatsuka, I. Ohnaka, J.D. Zhu, and T. Omichi, Mold filling simulation of high pressure die casting for predicting gas porosity, Model. Cast. Weld. Adv. Solidif. Process. 2003, p 335–342.

T. Sakuragi, Prediction of Gas Hole by Mold-Filling Simulation with Consideration of Surface Tension, JSME Int. J. B, 2004, 47(4), p 699–708

S.M. Xiong, F. Lau, and W.B. Lee, Numerical Methods to Improve the Computational Efficiency of Thermal Analysis for the Die Casting Process, J. Mater. Process. Technol., 2002, 128(1–3), p 19–24

M.R. Barkhudarov and C.W. Hirt, Casting Simulation: Mold Filling and Solidification—Benchmark Calculations Using FLOW-3D®, Technical Report, Flow Science, Inc., Santa Fe, 1993

C.W. Hirt and J.M. Sicilian, Proceedings of the 4th International Conference on ShiHydrodynamics, Washington, DC, September 1985.

T. Yoshimura, K. Yano, T. Fukui, S. Yamamoto, S. Nishido, M. Watanabe, and Y. Nemoto, Optimum Design of Die Casting Plunger Tip Considering Air Entrainment, Proceedings of 10th Asian Foundry Congress (AFC10), Nagoya, Japan, May 2008 20.

C.K. Jin and C.G. Kang, Fabrication Process Analysis and Experimental Verification for Aluminum Bipolar Plates in Fuel Cells by Vacuum Die-Casting, J. Power Sources, 2011, 196, p 8241–8249

W.P. Sequeira and G. L. Dunlop, Effect of Section Thickness and Microstructure on the Mechanical Properties of High Pressure Die Cast Magnesium Alloy AZ91D, 3rd International Magnesium Conference, Institute of Materials (UK), Manchester, England, 10–12 April 1996, p 63–73.

W.P. Sequeira, M.T. Murray, G.L. Dunlop, and D.H. StJohn, Effect of Section Thickness and Gate Velocity on the Microstructure andMechanical Properties of High Pressure Die Cast Magnesium Alloy AZ9I, Automotive Alloys, A Special symposium, TMS AnnualMeeting and Exhibition, Orlando, Florida, USA, February 9–13, 1997.

M.S. Dargusch, G.L. Dunlop, and K. Pettersen, Proc. Magnesium Alloys and Their Application, Wolfsburg, B.L. Mordike and K.V. Kainer, Eds., Warkstoff-Informationsgesellschaft mbh., Frankfurt, 1998, p 82–277.

ASM Handbook Committee: Metallography and Microstructures, ASM International, Metals Park, OH, 1985, p 425–434.

M. Nave, A.K. Dahle, and D.H. St John, The Effect of Solidification Rate on the structure of Magnesium-Aluminium Eutectic Grains, Int. J. Cast Met. Res., 2000, 13, p 1–7

Y. Chen, Q. Wang, J. Peng, C. Zhai, and W. Ding, Effects of Extrusion Ratio on the Microstructure and Mechanical Properties of AZ31 Mg Alloy, J. Mater. Process. Technol., 2007, 117, p 281–285

M.D. Nave, A.K. Dahle, and D.H. St John, TMS Annual Meeting, Nashville, TN, H.I. Kaplan, J.N. Hryn, and B.B. Clow, Eds., TMS, Warrendale, PA, March 2000, p 233–242.

C. Dørum, O.S. Hopperstad, T. Berstad, and D. Dispinar, Numerical Modeling of Magnesium Die-Castings Using Stochastic Fracture Parameters, Eng. Fract. Mech., 2009, 76, p 2232–2248

Acknowledgments

This research was supported by a grant from the Materials & Components Technology R&D Program Funded by The Ministry of Commerce, Industry and Energy, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, B.D., Baek, U.H. & Han, J.W. Optimization of Gating System Design for Die Casting of Thin Magnesium Alloy-Based Multi-Cavity LCD Housings. J. of Materi Eng and Perform 21, 1893–1903 (2012). https://doi.org/10.1007/s11665-011-0111-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-0111-1