Abstract

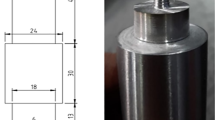

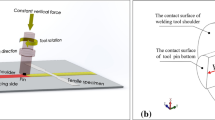

This study is concerned with the effect of friction stir welding (FSW) parameters on the mechanical properties and the consumed welding power for AA2024-T35 joints. AA2024-T35 is friction stir welded at different welding speeds (16, 40, and 80 mm/min), rotation speed (900, 1120, and 1400 rpm), and two tool profiles (triangular and square). The welding power is measured and evaluated with two previously established models (O. Frigaad, O. Grong, and O.T. Midling, A Process Model for Friction Stir Welding of Age Hardening Aluminum Alloys, Metall. Mater. Trans. A, 2001, 32A, p 1189–1200; O.P. Heurtier, M.J. Jones, C. Desrayaud, J.H. Driver, F. Montheillet, and D. Allehaux, Mechanical and Thermal Modelling of Friction Stir Welding, J. Mater. Process. Technol., 2006, 171, p 348–357). The tool profile as well as the welding speed show significant effect on the microstructure especially at lower welding speeds. The increase of the welding speed improves the mechanical properties for both tool profiles whereas it has an insignificant effect on the welding power. The square profile produces better mechanical properties and consumed more power, at 40 mm/min, than the triangular one. Moreover, the welding speed showed a weak effect on the welding power, but the need of power increased with the increase of the rotation speed. The measured power is found to be in agreement with the computed one through a theoretical work established by Heurtier et al. (Mechanical and Thermal Modelling of Friction Stir Welding, J. Mater. Process. Technol., 2006, 171, p 348–357).

Similar content being viewed by others

References

K. Elangovan and V. Balasubramanian, Influences of Tool Pin Profile and Welding Speed on the Formation of Friction Stir Processing Zone in AA2219 Aluminum Alloy, Mater. Sci. Eng. A, 2007, 459(1–2), p 7–18

H.W. Zhang, Z. Zhang, and J.T. Chen, The Finite Element Simulation of the Friction Stir Welding Process, Metall. Mater. Trans. A, 2005, 403, p 305–316

http://www.esabna.com/us/en/education/knowledge/images/FrictionStirWeldingChart.jpg, 7 Dec. 2009

H. Zhang, S.B. Lin, L. Wu, J.C. Feng, and Sh.L. Ma, Defects Formation Procedure and Mathematic Model for Defect Free Friction Stir Welding of Magnesium Alloy, Mater. Des., 2006, 27, p 805–809

W.B. Lee, Y.M. Yeon, and S.B. Jung, Mechanical Properties Related to Microstructural Variation of 6061 Al Alloy Joints by Friction Stir Welding, Mater. Trans., 2004, 45(6061), p 1700–1705

S.R. Ren, Z.Y. Ma, and L.Q. Chen, Effect of Welding Parameters on Tensile Properties and Fracture Behavior of Friction Stir Welded A-Mg-Si alloy, Scr. Mater., 2007, 56, p 69–72

S. Lim, S. Kim, C.G. Lee, and S. Kim, Tensile Behavior of Friction-Stir-Welded Al 6061-T651, Metall. Mater. Trans. A, 2004, 35A, p 2829–2835

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1–78

F.C. Liu and Z.Y. Ma, Influence of Tool Dimension and Welding Parameters on Microstructure and Mechanical Properties of Friction-Stir-Welded 6061-T651 Aluminum Alloy, Metall. Mater. Trans. A, 2008, 39A, p 2378–2388

P. Vilac, L. Quintino, and J.F. dos Santos, Analytical Thermal Model for Friction Stir Welding, J. Mater. Process. Technol., 2005, 169, p 452–465

M.Z.H. Khandkar, J.A. Khan, and A.P. Reynolds, Prediction of Temperature Distribution and Thermal History During Friction Stir Welding: An Input Torque Based Model, Sci. Technol. Weld. Join., 2003, 8(3), p 165–174

H. Schmidt, J. Hattel, and J. Wert, An Analytical Model for the Heat Generation in Friction Stir Welding, Model. Simul. Mater. Sci. Eng., 2004, 12, p 143–157

R. Nandan, T.J. Lienert, and T. DebRoy, Toward Reliable Calculations of Heat and Plastic Flow During Friction Stir Welding of Ti-6Al-4V Alloy, Int. J. Mater. Res., 2008, 99(4), p 434–444

R. Nandan, G.G. Roy, T.J. Lienert, and T. DebRoy, Numerical Modelling of 3D Plastic Flow and Heat Transfer During Friction Stir Welding of Stainless Steel, Sci. Technol. Weld. Join., 2006, 11(5), p 526–537

R. Nandan, G.G. Roy, T.J. Lienert, and T. DebRoy, Three-Dimensional Heat and Material Flow During Friction Stir Welding of Mild Steel, Acta Mater., 2007, 55(3), p 883–895

A. Arora, R. Nandan, A.P. Reynolds, and T. DebRoy, Torque, Power Requirement and Stir Zone Geometry in Friction Stir Welding Through Modeling and Experiments, Scr. Mater., 2009, 60, p 13–16

A. El-Domiaty and H. Abd El-Hafez, An Energy Model for Friction Stir Welding, Mater. Sci. Technol. Assoc. Iron Steel Technol., 2007, 3, p 1709–1721

Z. Zhang and H.W. Zhang, Numerical Studies on the Effect of Axial Pressure in Friction Stir Welding, Sci. Technol. Weld. Join., 2007, 12, p 226–248

Z. Zhang and H.W. Zhang, A Fully Coupled Thermo-Mechanical Model of Friction Stir Welding, Int. J. Adv. Manuf. Technol., 2008, 37, p 279–293

Z. Zhang and H.W. Zhang, Numerical Studies on Controlling of Process Parameters in Friction Stir Welding, J. Mater. Process. Technol., 2009, 209, p 241–270

Z. Zhang and H.W. Zhang, Numerical Studies on the Effect of Transverse Speed in Friction Stir Welding, Mater. Des., 2009, 30, p 900–907

O. Frigaad, O. Grong, and O.T. Midling, A Process Model for Friction Stir Welding of Age Hardening Aluminum Alloys, Metall. Mater. Trans. A, 2001, 32A, p 1189–1200

O.P. Heurtier, M.J. Jones, C. Desrayaud, J.H. Driver, F. Montheillet, and D. Allehaux, Mechanical and Thermal Modelling of Friction Stir Welding, J. Mater. Process. Technol., 2006, 171, p 348–357

G. Abd El-Nasser, A. El-Bagdady, and H. Abd El-Hafez, Effect of the Friction Stir Welding Parameters on the Mechanical Properties of Al 5083 Joint, Al-Azahar Eng. 9th Int. Conf., 12–14 April 2007, Cairo, Egypt, p 356–367

C.K. Alexander and M.N.O. Sadiku, Fundamentals of Electric Circuits, 2nd ed., Chap. 12, Mc-Graw-Hill, 2000

M.A. Sutton, B. Yang, A.P. Reynolds, and R. Taylor, Microstructural Studies of Friction Stir Welds in 2024-T3 Aluminum, Mater. Sci. Eng., 2002, A323, p 160–166

S.A. Khodir and T. Shibayanagi, Friction Stir Welding of Dissimilar AA2024 and AA7075 Aluminum Alloys, Mater. Sci. Eng. B, 2008, 148(1–3), p 82–87

K. Elangovan, V. Balasubramanian, and S. Babu, Predicting Tensile Strength of Friction Stir Welded AA6061 Aluminium Alloy Joints by a Mathematical Model, Mater. Des., 2009, 30, p 188–193

C. S. Babu, A.S. El-Gizawy, and A. Sherif, Characterization of Friction Stir Welding Process Behaviour Using Numerical and Physical Modeling Techniques, Proc. of the 9th Int. Conf. Mech. Des. Prod. (MDP-9), 8–10 Jan 2008, Cairo, Egypt, p 517–530

W.B. Lee, Y.M. Yeon, and S.B. Jung, Evaluation of the Microstructure and Mechanical Properties of Friction Stir Welded 6005 Aluminum Alloy, Mater. Sci. Technol., 2003, 19, p 1513–1518

H. Atharifar, D. Lin, and R. Kovacevic, Numerical and Experimental Investigations on the Loads Carried by the Tool During Friction Stir Welding, J. Mater. Eng. Perform., 2008, 18, p 339–350

P.A. Colegrove and H.R. Shercliff, 3-Dimensional CFD Modelling of Flow Round a Threaded Friction Stir Welding Tool Profile, J. Mater. Process Technol., 2005, 169, p 320–327

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abd El-Hafez, H. Mechanical Properties and Welding Power of Friction Stirred AA2024-T35 Joints. J. of Materi Eng and Perform 20, 839–845 (2011). https://doi.org/10.1007/s11665-010-9709-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9709-y