Abstract

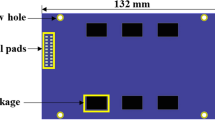

Fatigue life predictions for ball grid arrays (BGA) in electronic devices under random vibration have been made using the finite element method (FEM). Three different circuit board configurations were investigated to determine the best system design for longer fatigue lifetime. Moreover, to reveal the effect of the input frequency, different acceleration power spectral density (PSD) values were applied to the systems. The root-mean-square peeling stress was selected as the failure indicator. FEM results showed that the maximum peeling stress occurred at the outermost corners of solder joints adjacent to the printed circuit board in BGA packages. It was also found that, with increase in the input PSD, solder joints in BGA packages were more exposed to failure. Furthermore, it was revealed that the location of different parts of the system on the board can influence the stress distribution. The results show that a system with a heat sink at the corner of the board, away from the BGA packages, showed the longest fatigue life among the designed configurations.

Similar content being viewed by others

References

A.E. Perkins and S.K. Sitaraman, editors, Solder Joint Reliability Prediction for Multiple Environments (Springer US, Boston, MA, 2009), pp. 1–22

J. Xia, L. Cheng, G. Li, and B. Li, Microelectron. Reliab. 78, 285 (2017).

M.S. Kang, Y.J. Jeon, D.S. Kim, and Y.E. Shin, Int. J. Precis. Eng. Manuf. 16, 2483 (2015).

V. Samavatian, H. Iman-eini, and Y. Avenas, Int. J. Fatigue 116, 284 (2018).

J. Jang, G. Jang, J. Lee, Y. Cho, and Y. Cinar, Int. J. Fatigue 88, 42 (2016).

F. Liu, Y. Lu, Z. Wang, and Z. Zhang, Microelectron. Reliab. 55, 2777 (2015).

D. Ghaderi, M. Pourmahdavi, V. Samavatian, O. Mir, and M. Samavatian, in Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 1464420718780525 (2018).

T.Y. Tsai, C.L. Yeh, Y.S. Lai, and R.S. Chen, IEEE Trans. Electron. Packag. Manuf. 30, 54 (2007).

Y. Cinar and G. Jang, J. Mech. Sci. Technol. 28, 107 (2014).

J. Xia, G. Li, B. Li, L. Cheng, and B. Zhou, Microelectron. Reliab. 71, 111 (2017).

L.S. Han, C.Y. Huang, R. Yin, L. Ying, G. x. Huang, and T.M. Li, in 2017 18th Int. Conf. Electron. Packag. Technol. (2017), pp. 632–638

J.H. Lee and H.-Y. Jeong, Int. J. Fatigue 61, 264 (2014).

M. Jannoun, Y. Aoues, E. Pagnacco, P. Pougnet, and A. El-Hami, Microelectron. Reliab. 78, 249 (2017).

C. Choi and A. Dasgupta, Procedia Eng. 74, 165 (2014).

C.-U. Kim, W.-H. Bang, H. Xu, and T.-K. Lee, JOM 65, 1362 (2013).

Y. Chen, B. Jing, Z. Sheng, F. Lu, J. Hu, and S. Si, in 2017 Progn. Syst. Heal. Manag. Conf. (2017), pp. 1–5

N. Patin, in edited by N. B. T.-P. E. A. to I. S. and T. Patin, Power Electronics Applied to Industrial Systems and Transports, Vol. 1 (Elsevier, 2015), pp. 117–135.

G. Schmid, L.G. Valladares-Rendón, T.-H. Yang, and S.-L. Chen, Appl. Therm. Eng. 125, 575 (2017).

M. Mihalis, US6778390B2 (2001).

A. Letellier, M. Dubois, J.P.F. Trovao, and H. Maher, IEEE Trans. Power Electron. 1 (2018).

U.M. Choi, F. Blaabjerg, and S. J⊘rgensen, in 2016 IEEE Energy Convers. Congr. Expo. (2016), pp. 1–7

F. Liu, G. Meng, M. Zhao, and J. Zhao, J. Electron. Packag. 130, 21006 (2008).

J.H.L. Pang, F.L. Wong, K.T. Heng, Y.S. Chua, and C.E. Long, in 2013 IEEE 63rd Electron. Components Technol. Conf. (2013), pp. 1300–1307

R.F. Fang Liu, Adv. Vib. Eng. 12, 489 (2013).

F. Liu and G. Meng, Microelectron. Reliab. 54, 226 (2014).

F.X. Che and J.H.L. Pang, Microelectron. Reliab. 49, 754 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samavatian, M., Ilyashenko, L.K., Surendar, A. et al. Effects of System Design on Fatigue Life of Solder Joints in BGA Packages Under Vibration at Random Frequencies. J. Electron. Mater. 47, 6781–6790 (2018). https://doi.org/10.1007/s11664-018-6600-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6600-3