Abstract

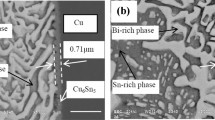

The microstructure of microscale solder interconnects and soldering defects have long been known to have a significant influence on the reliability of electronic packaging, and both are directly related to the solidification behavior of the undercooled solder. In this study, the undercooling behavior and solidification microstructural evolution of Sn-3.0Ag-0.5Cu solder balls with different diameters (0.76 mm, 0.50 mm, and 0.30 mm) and the joints formed by soldering these balls on Cu open pads of two diameters (0.48 mm and 0.32 mm) on a printed circuit board (PCB) substrate were characterized by differential scanning calorimetry (DSC) incorporated into the reflow process. Results show that the decrease in diameter of the solder balls leads to an obvious increase in the undercooling of the balls, while the undercooling of the solder joints shows a dependence on both the diameter of the solder balls and the diameter ratio of solder ball to Cu pad (i.e., D s/D p), and the diameter of the solder balls has a stronger influence on the undercooling of the joints than the dimension of the Cu pad. Coarse primary intermetallic compound (IMC) solidification phases were formed in the smaller solder balls and joints. The bulk Ag3Sn IMC is the primary solidification phase in the as-reflowed solder balls. Due to the interfacial reaction and dissolution of Cu atoms into the solder matrix, the primary Ag3Sn phase can be suppressed and the bulk Cu6Sn5 IMC is the only primary solidification phase in the as-reflowed solder joints.

Similar content being viewed by others

References

K.S. Kim, S.H. Huh, and K. Suganuma, J. Alloys Compd. 352, 226 (2003).

P. Zimprich, U. Saeed, A. Betzwar-Kotas, B. Weiss, and H. Ipser, J. Electron. Mater. 37, 102 (2008).

L.M. Yin, X.P. Zhang, and C. Lu, J. Electron. Mater. 38, 2179 (2009).

Y.H. Tian, C.J. Hang, C.Q. Wang, S.H. Yang, and P.R. Lin, Mater. Sci. Eng. A 529, 468 (2011).

W.B. Guan, Y.L. Gao, Q.J. Zhai, and K.D. Xu, J. Mater. Sci. 39, 4633 (2004).

R. Kinyanjui, L.P. Lehman, L. Zavalij, and E. Cotts, J. Mater. Res. 20, 2914 (2005).

Q.J. Zhai, Y.L. Gao, W.B. Guan, and K.D. Xu, Mater. Sci. Eng. A 441, 278 (2006).

Y.C. Huang, S.W. Chen, and K.S. Wu, J. Electron. Mater. 39, 109 (2010).

S.K. Kang, D.Y. Shih, D. Leonard, D.W. Henderson, T. Gosselin, S. Cho, J. Yu, and W. Choi, JOM 56, 34 (2004).

L.W. Lin, J.M. Song, Y.S. Lai, Y.T. Chiu, N.C. Lee, and J.Y. Uan, Microelectron. Reliab. 49, 235 (2009).

M.G. Cho, H.Y. Kim, S.K. Seo, and H.M. Lee, Appl. Phys. Lett. 95, 021905 (2009).

S.K. Kang, M.G. Cho, P. Lauro, and D.Y. Shih, J. Mater. Res. 22, 557 (2007).

M.G. Cho, S.K. Kang, and H.M. Lee, J. Mater. Res. 23, 1147 (2008).

M.G. Cho, S.K. Kang, S.K. Seo, D.Y. Shih, and H.M. Lee, J. Mater. Res. 24, 534 (2009).

M. Abtew and G. Selvaduray, Mater. Sci. Eng. R 27, 95 (2000).

C.M.L. Wu, D.Q. Yu, C.M.T. Law, and L. Wang, Mater. Sci. Eng. R 44, 1 (2004).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R 38, 55 (2002).

K.N. Tu, A.M. Gusak, and M. Li, J. Appl. Phys. 93, 1335 (2003).

Y.C. Chan and D. Yang, Prog. Mater Sci. 55, 428 (2010).

S.W. Chen, C.C. Lin, and C. Chen, Metall. Mater. Trans. A 29, 1965 (1998).

D. Turnbull, J. Chem. Phys. 20, 411 (1952).

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys, 2nd ed. (London: Chapman and Hall, 1992), p. 190.

D.M. Herlach and F. Gillessen, J. Phys. F 17, 1635 (1987).

W. Kurz and D.J. Fisher, Fundamentals of Solidification (Switzerland: Trans Tech publications, 1984), p. 21.

S. Gruner, I. Kaban, R. Kleinhempel, W. Hoyer, P. Jóvári, and R.G. Delaplane, J. Non-Cryst. Solids 351, 3490 (2005).

Y. Takamatsu, H. Esaka, and K. Shinozuka, Mater. Sci. Forum 654–656, 1397 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, M.B., Ma, X. & Zhang, X.P. Undercooling Behavior and Intermetallic Compound Coalescence in Microscale Sn-3.0Ag-0.5Cu Solder Balls and Sn-3.0Ag-0.5Cu/Cu Joints. J. Electron. Mater. 41, 3169–3178 (2012). https://doi.org/10.1007/s11664-012-2203-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-012-2203-6