Abstract

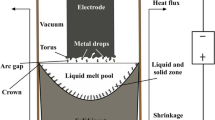

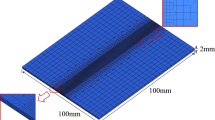

The assumption of transient rotating arc distribution is more closer to the actual vacuum arc remelting (VAR) process, but there is still a lack of relevant research on the grain structure under the rotating arc. Based on this, a three-dimensional transient full-size CAFE model coupled with heat transfer, fluid flow, solidification, and grain nucleation is developed to predict the grain structure, which is validated by comparing the predicted results with the experimental observation. The heating effect of the electric arc on the molten pool is innovatively considered by incorporating a volume heat source in the form of a dynamic thin layer moving upward with ingot growth. The effects of melting rate, gas cooling, and nucleation parameters on the grain structure are studied, respectively, by this model. The results show that the proportion of equiaxed grain increases from 30.9 to 43.1 pct with the melting rate increasing from 0.048 to 0.072 kg/s. As the equivalent heat transfer coefficient in the shrinkage gap increases from a small value of radiation to 400 W/(m2 K), the proportion of equiaxed grain decreases from 37.2 to 18.0 pct. Increasing the melting rate can significantly refine the grains, while the effect caused by gas cooling is just the opposite. With the increase of the mean undercooling, the central equiaxed grain region is reduced and the mean surface area greatly increases, which is also contrary to the effect of the maximum volume nucleation density on the grain structure.

Similar content being viewed by others

References

P.O. Delzant, B. Baqué, P. Chapelle, and A. Jardy: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 958–68.

G. Ghazal, A. Jardy, P. Chapelle, and Y. Millet: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 646–59.

Y.D. Wang, L.F. Zhang, J. Zhang, Y. Zhou, T.Y. Liu, Y. Ren, and D.B. Jiang: Steel Res. Int., 2022, vol. 93, p. 2100408.

L. Nastac, S. Sundarraj, K.O. Yu, and Y. Pang: JOM, 1998, vol. 50, pp. 30–35.

H.C. Kou, Y.J. Zhang, P.F. Li, H. Zhong, R. Hu, J.S. Li, and L. Zhou: Rare Metal Mat. Eng., 2014, vol. 43, pp. 1537–42.

Y.S. Huang, M.S. Yang, J.S. Li, and L.G. Bai: Mater. Sci. Forum, 2015, vol. 817, pp. 826–36.

A. Kermanpur, D.G. Evans, R.J. Siddall, P.D. Lee, and M. Mclean: J. Mater. Sci., 2004, vol. 39, pp. 7175–82.

X. Xu, W. Zhang, and P.D. Lee: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1805–15.

C.R. Woodside, P.E. King, and C. Nordlund: Metall. Mater. Trans. B, 2013, vol. 44b, pp. 154–65.

D.M. Shevchenko and R.M. Ward: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 263–70.

K. Pericleous, G. Djambazov, M. Ward, L. Yuan, and P.D. Lee: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5365–76.

E. Karimi-Sibaki, A. Kharicha, A. Vakhrushev, M. Abdi, M. Wu, A. Ludwig, J. Bohacek, and B. Preiss: J. Mater. Res. Technol, 2022, vol. 19, pp. 183–93.

J.J. Cui, B.K. Li, Z.Q. Liu, F.S. Qi, J.X. Xu, and J. Zhang: J. Mater. Res. Technol, 2022, vol. 18, pp. 3991–4006.

K. Mramor, T. Quatravaux, H. Combeau, A. Jardy, M. Založnik, I. Crassous, and A. Gaillac: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 2953–71.

J.J. Cui, B.K. Li, Z.Q. Liu, F.S. Qi, B.J. Zhang, and J. Zhang: Metals, 2021, vol. 11, p. 2046.

X.H. Wang and Y. Li: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 800–12.

Z.H. Wang, S. Luo, W.L. Wang, and M.Y. Zhu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2882–94.

P. Peng, L. Lu, Z.J. Liu, Y.L. Xu, X.D. Zhang, Z.K. Ma, H. Zhang, M. Guo, and L. Liu: J. Alloys Compd., 2022, vol. 927, 167009.

S. Tin and T.M. Pollock: J. Mater. Sci., 2004, vol. 39, pp. 7199–7205.

Z.C. Wang, J.R. Li, S.Z. Liu, J.Q. Zhao, X.G. Wang, and W.P. Yang: J. Alloys Compd., 2022, vol. 918, 165631.

P.K. Sung and D.R. Poirier: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2173–81.

S. Spitans, H. Franz, H. Scholz, G. Reiter, and E. Baake: Magnetohydrodynamics, 2017, vol. 53, pp. 557–70.

J.J. Cui, B.K. Li, Z.Q. Liu, F.S. Qi, and X.P. Zhang: J. Mater. Res. Technol, 2022, vol. 20, pp. 1912–26.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51934002), National Science and Technology Major Project (J2019-VI-0005-0119), Youth Innovation Promotion Association CAS (No. 2020193), and 111 Project (B16009). The authors are grateful for their financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, J., Li, B., Liu, Z. et al. Numerical Investigation of Grain Structure Under the Rotating Arc Based on Cellular Automata-Finite Element Method During Vacuum Arc Remelting Process. Metall Mater Trans B 54, 661–672 (2023). https://doi.org/10.1007/s11663-022-02716-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02716-x