Abstract

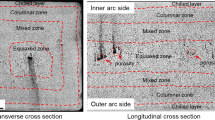

Three-dimensional characterization of defects in continuous casting blooms of a heavy rail steel with different electromagnetic stirring intensities at the solidification end, also named final electromagnetic stirring, was performed employing a laboratory-based X-ray computed tomography to evaluate the effect of final electromagnetic stirring on the internal quality of blooms. The three-dimensional distribution and morphology of defects including porosities and oxide inclusions in blooms were characterized. The amount, size and shape complexity of defects increased gradually from the loose-side surface to the center of blooms. The total volume fraction of defects was 5265 and 3942 ppm when the current of final electromagnetic stirring was 200 and 300 A, respectively. The sphericity of defects varied from 0.1 to 0.75, and the equivalent spherical diameter varied between 20 and 450 μm. Most defects with a sphericity > 0.6 were nearly spherical and were assumed to be oxide inclusions. The volume fraction of both porosities and inclusions was small in the chilled layer and the columnar crystal zone and then increased rapidly toward the equiaxed zone. Increasing the current of F-EMS from 200 to 300 A significantly decreased the volume fraction of porosities in the center of the bloom from 2906 to 1873 ppm. It could also decrease the volume fraction and average diameter of oxide inclusions in the bloom by reducing the number of large inclusions.

Similar content being viewed by others

References

1. S. Minakawa, I.V. Samarasekera and F. Weinberg: Metall. Trans. B, 1985, vol. 16, pp. 823-29.

2. E. Niyama, T. Uchida, M. Morikawa and S. Saito: Int. Cast Met. J., 1981, vol. 6, pp. 16-22.

3. E. Niyama, T. Uchida, M. Morikawa and S. Saito: AFS Int. Cast. Met. J., 1982, vol. 7, pp. 52-63.

4. H. An, Y. Bao, M. Wang, Q. Yang, X. Wang and Y. Dang: Metall. Res. Technol., 2019, vol. 116, pp. 621.

5. H. An, Y. Bao, M. Wang, Q. Yang and Y. Dang: Ironmaking Steelmaking, 2020, vol. 47, pp. 1063-77.

6. A. Costa: J. Mater. Res. Technol., 2019, vol. 8, pp. 2408-22.

7. C. Yang, P. Liu, Y. Luan, D. Li and Y. Li: Int. J. Fatigue, 2019, vol. 128, pp. 105193.

M. Wu, W. Fang, R. Chen, B. Jiang, H. Wang, Y. Liu and H. Liang: Mater. Sci. Eng. A, 2019, vol. 744, pp. 324-34.

9. H. Fu, J.J. Rydel, A.M. Gola, F. Yu, K. Geng, C. Lau, H. Luo and E.J. Rivera: Int. J. Fatigue, 2019, vol. 129, pp. 104899.

10. H. Li, L. Wang, H. Xiao, J. Xu, S. Zheng, Q. Zhai and K. Han: Metall. Mater. Trans. A, 2018, vol. 50, pp. 336-47.

11. L. Zhang and S. Taniguchi: Int. Mater. Rev., 2000, vol. 45, pp. 59-82.

12. Y. Ren, L. Zhang, W. Fang, S. Shao, J. Yang and W. Mao: Metall. Mater. Trans. B, 2016, vol. 47, pp. 1024-34.

13. W. Yang, L. Zhang, X. Wang, Y. Ren, X. Liu and Q. Shan: ISIJ Int., 2013, vol. 53, pp. 1401-10.

14. S. Yang, Q. Wang, L. Zhang, J. Li and K. Peaslee: Metall. Mater. Trans. B, 2012, vol. 43, pp. 731-50.

15. L. Zhang: JOM, 2013, vol. 65, pp. 1138-44.

16. J. Lehmann, P. Rocabois and H. Gaye: J. Non-Cryst. Solids, 2001, vol. 282, pp. 61-71.

17. W. Yang, C. Guo, C. Li and L. Zhang: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2267-73.

18. G. Cheng, L. Zhang and Y. Ren: Ironmaking Steelmaking, 2020, vol. 47, pp. 1217-25.

19. Y. Ren and L. Zhang: Ironmaking Steelmaking, 2019, vol. 46, pp. 558-63.

20. L. Gui, M. Long, Y. Huang, D. Chen, H. Chen, H. Duan and S. Yu: Metall. Mater. Trans. B, 2018, vol. 49, pp. 3280-92.

21. Y. Chu, W. Li, Y. Ren and L. Zhang: Metall. Mater. Trans. B, 2019, vol. 50, pp. 2047-62.

22. Y. Ren, L. Zhang and P.C. Pistorius: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2281-92.

23. J. Wang, W. Li, Y. Ren and L. Zhang: Steel Res. Int., 2019, vol. 90, pp. 1800600.

24. W. Yang, C. Guo, L. Zhang, H. Ling and C. Li: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2717-30.

25. L. Zhang, C. Guo, W. Yang, Y. Ren and H. Ling: Metall. Mater. Trans. B, 2018, vol. 49, pp. 803-11.

26. J. Kastner, B. Harrer and H.P. Degischer: Mater. Charact., 2011, vol. 62, pp. 99-107.

27. T. Li, S. Shimasaki, S. Taniguchi, K. Uesugi and S. Narita: ISIJ Int., 2013, vol. 53, pp. 1943-52.

28. T. Li, S.I. Shimasaki, S. Taniguchi, S. Narita and K. Uesugi: ISIJ Int., 2016, vol. 56, pp. 1989-95.

29. J. Yan, T. Li, Z. Shang and H. Guo: Mater. Charact., 2019, vol. 158, pp. 109944.

30. W. Yang, L. Zhang, Y. Ren, H. Duan, Y. Zhang and X. Xiao: Acta Metall. Sinica, 2015, vol. 52, pp. 217-23.

D. Kumar, R. Cunningham and P. Chris Pistorius: AISTech 2018 Iron and Steel Technology Conference and Exposition, United states, 2018, pp. 1493–1500.

32. X. Zhang, L. Zhang, W. Yang and Y. Dong: Steel Res. Int., 2017, vol. 88, pp. 1600080.

33. Q. Dong, J. Zhang and X. Zhao: Metall. Res. Technol., 2017, vol. 114, pp. 303.

34. T. Piwonka and M. Flemings: Trans. Metall. Soc. of AIME, 1966, vol. 36, pp. 1157-65.

35. T. Piwonka, S. Kuyucak and K. Davis: Trans. Am. Foundry Soc., 2002, vol. 113, pp. 1257-71.

36. D. Li, X. Chen, P. Fu, X. Ma, H. Liu, Y. Chen, Y. Cao, Y. Luan and Y. Li: Nat. Commun., 2014, vol. 5, pp. 5572.

37. Y. Cao, Y. Chen and D. Li: Acta Mater., 2016, vol. 107, pp. 325-36.

Acknowledgments

The authors are grateful for support from the National Natural Science Foundation of China (Grant Nos. 51874031, U1860206, 51725402), the Fundamental Research Funds for the Central Universities (Grant No. FRF-BD-20-04A), the S&T Program of Hebei (Grant Nos. 20311004D, 20311005D, 20311006D, 20591001D), the High Steel Center (HSC), Hebei Innovation Center of the Development and Application of High Quality Steel Materials, Hebei International Research Center of Advanced and Intelligent Manufacturing of High Quality Steel Materials at Yanshan University, and Beijing International Center of Advanced and Intelligent Manufacturing of High Quality Steel Materials (ICSM) at the University of Science and Technology Beijing, China.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted 11 January 2021; accepted 2 April 2021.

Rights and permissions

About this article

Cite this article

Cui, L., Lei, X., Zhang, L. et al. Three-Dimensional Characterization of Defects in Continuous Casting Blooms of Heavy Rail Steel Using X-ray Computed Tomography. Metall Mater Trans B 52, 2327–2340 (2021). https://doi.org/10.1007/s11663-021-02172-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02172-z