Abstract

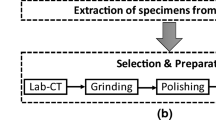

AM60 high pressure die castings have been used in automobile applications to reduce the weight of vehicles. However, the pore defects that are inherent in die casting may negatively affect mechanical properties, especially the fatigue properties. Here we have studied damage (e.g., pore defects, fatigue cracks) during strained-controlled fatigue using 3-dimensional X-ray computed tomography (XCT). The fatigue test was interrupted every 2000 cycles and the specimen was removed to be scanned using a desktop micro-CT system. XCT reveals pore defects, cracks, and fracture surfaces. The results show that pores can be accurately measured and modeled in 3D. Defect bands are found to be made of pores under 50 µm (based on volume-equivalent sphere diameter). Larger pores are randomly distributed in the region between the defect bands. Observation of fatigue cracks by XCT is performed in three ways such that the 3D model gives the best illustration of crack–porosity interaction while the other two methods, with the cracks being viewed on transverse or longitudinal cross sections, have better detectability on crack initiation and crack tip observation. XCT is also of value in failure analysis on fracture surfaces. By assessing XCT data during fatigue testing and observing fracture surfaces on a 3D model, a better understanding on the crack initiation, crack–porosity interaction, and the morphology of fracture surface is achieved.

Similar content being viewed by others

References

A. A. Luo: Journal of Magnesium and Alloys, 2013, vol. 1, pp. 2–22.

S. Mohd, Y. Mutoh, Y. Otsuka, Y. Miyashita, T. Koike, and T. Suzuki: Eng. Failure Anal., 2012, vol. 22, pp. 64–72.

L. H. Rettberg, J. B. Jordon, M. F. Horstemeyer, and J. W. Jones: Metall. Mater. Trans. A, 2012, vol. 43, pp. 2260–2274.

E. Maire and P. J. Withers: Int. Mater. Rev., 2014, vol. 59, pp. 1–43.

J.-Y. Buffière, S. Savelli, P. H. Jouneau, E. Maire, and R. Fougères: Mater. Sci. Eng. A, 2001, vol. 316, pp. 115–126.

A. King, W. Ludwig, M. Herbig, J.-Y. Buffière, A. A. Khan, N. Stevens, and T. J. Marrow: Acta Mater., 2011, vol. 59, pp. 6761–6771.

W. Ludwig, J.-Y. Buffière, S. Savelli, and P. Cloetens: Acta Mater., 2003, vol. 51, pp. 585–598.

T.J. Marrow, J.-Y. Buffiere, P.J. Withers, G. Johnson, and D. Engelberg: Int. J. Fatigue, 2004, vol. 26, pp. 717–725.

H. Toda, S. Masuda, R. Batres, M. Kobayashi, S. Aoyama, M. Onodera, R. Furusawa, K. Uesugi, A. Takeuchi, and Y. Suzuki: Acta Mater., 2011, vol. 59, pp. 4990–4998.

W. Elber: Ph.D. Thesis, University of New South Wales, Australia, 1968.

W., Elber: Eng. Fract. Mech., 1970, vol. 2, pp. 37-44.

Acknowledgments

The financial support from the Federal Inter-developmental Program on Energy R&D (PERD) is acknowledged. Connie Barry (McMaster University), J.P. Talon, Jie Liang and Mark Gesing (CanmetMATERIALS) are acknowledged for their help on various aspects of the experimental and modeling work. The shock towers were provided through the Canada-China-USA Collaborative Research & Development Project, Magnesium Front End Research and Development (MFERD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published with permission of the Crown in Right of Canada.

Manuscript submitted February 6, 2015.

Rights and permissions

About this article

Cite this article

Yang, Z., Kang, J. & Wilkinson, D.S. Characterization of Pore Defects and Fatigue Cracks in Die Cast AM60 Using 3D X-ray Computed Tomography. Metall Mater Trans B 46, 1576–1585 (2015). https://doi.org/10.1007/s11663-015-0370-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0370-6