Abstract

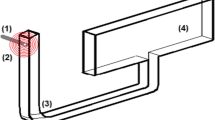

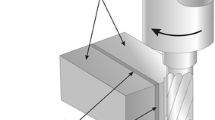

Positron emission particle tracking (PEPT) employs a radioactive particle that decays by emission of positrons. These positrons collide with local electrons to produce γ-rays emitted at 180 deg to each other; detection of these γ-ray pairs allows the location of the radioactive particle to be identified within a few millimeters. This technique has been tested to determine its applicability to the study of inclusions in cast metals. To use particles representative of inclusion sizes in castings, both alumina particles and particles of an ion exchange resin were employed. These were within a size range of approximately 60 to 100 μm, made radioactive by adsorption and ion exchange techniques, respectively. The radioactive particles, of activity 100 to 1000 μCi, were introduced into tube-shaped castings made from the low-melting-point alloys Field’s metal and Lensalloy-136, cast into an acrylic mold. The technique allowed the particle track to be determined from the point of initial introduction to the final resting place of the particle, with increasing reproducibility being obtained as the reproducibility as the casting technique was improved. Experiments in which filters were placed in to the running system showed that the removal of the particles by the filters varied according to the filter pore size.

Similar content being viewed by others

References

M. Trokar, B. Breskvar, M. Tandler, D. Mandrino, and M. Dobersek: Vacuum, 2001, vol. 62, pp. 379–85.

R. Kiessling: Non-Metallic Inclusions in Steel, Parts I-IV, The Institute of Materials, London, UK, 1976.

P.K. Trojan: Metals Handbook, vol. 9, ASM International, Materials Park, OH, 1999.

Z.B. Wen, R.Z. Ming, and W.J. Wiong: Trans. Nonferrous Metals Soc. China, 2006, vol. 16, pp. 33–38.

V.P. Sylovanyuk, O.A. Mityaev, A.E. Ostrovs’ka, N.A. Ivantyshyn, and I.P. Volchok: Mater. Sci., 2009, vol. 45, pp. 299–308.

R.V. Vainola, L.E.K. Holappa, and P.H.J. Karvonen: J. Mater. Process. Tech. A, 2008, vol. 495A, pp. 316–19.

D.T. Llewellyn and R.C. Hudd: Steels: Metallurgy and Applications, Butterworth-Heinemann, Burlington, MA, 2000.

Y.B. Kang, H.S. Kim, J. Zhang, and H.G. Lee: J. Phys. Chem. Solids, 2005, vol. 66, pp. 219–25.

M. Zhou, D. Shu, K. Li, W.Y. Zhang, H.J. Ni, B.D. Sun, and J. Wang: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1183–91.

K.C. Mills: A Literature Review of Inclusion Removal by Filtration and Floatation, National Physical Laboratory, Teddington, UK, 1991.

Z.L. Feng: J. Iron Steel Res. Int., 2006, vol. 13, pp. 1–8.

Y. Qiang, Z.Z. Shu, and H.Q. Fu: J. Iron Steel Res. Int., 2010, vol. 17, pp. 6–10.

MagmaSoft. www.magmasoft.de.

Flow-3D. www.flow3d.com.

L. Zhang and B.G. Thomas: J. Univ. Sci. Technol. Beijing, 2006, vol. 13, pp. 293–300.

T.F. Budinger and H.F. VanBrocklin: The Biomedical Engineering Handbook, CRC Press LLC, Boca Raton, FL, 2000.

D.J. Parker, C.J. Broadbent, P. Fowles, M.R. Hakesworth, and P. McNeil: Nucl. Instr. Methods Phy. Res., 1993, vol. A326, pp. 592–607.

D.J. Parker, T.W. Leadbeater, X. Fan, M.N. Hausard, A. Ingram, and Z. Wang: Meas. Sci. Tech., 2008, vol. 19, p. 094004.

J.R. Jones and J. Bridgwater: Int. J. Min. Proc., 1998, vol. 53, pp. 29–38.

B.P.B. Hoomans, J.A.M. Kuipers, M.A. Salleh, M. Stien, and J.P.K. Seville: Powder Tech., 2001, vol. 116, pp. 166–77.

P.G. Fairhurst, M. Barigou, P.J. Fryer, J.P. Pain, and D.J. Parker: Int. J. Multiphase Flow, 2001, vol. 27, pp. 1881–1901.

S. Bakalis, P.W. Cox, A.B. Russel, D.J. Parker, and P.J. Fryer: Chem. Eng. Sci., 2006, vol. 61, pp. 1864–77.

S. Bakalis, P.W. Cox, W.W. Nolan, D.J. Parker, and P.J. Fryer: J. Food Science, 2003, vol. 68, pp. 2684–92.

K. Mehauden, P.W. Cox, S. Bakalis, P.J. Fryer, X. Fan, D.J. Parker, and M.J.H. Simmons: Innovat. Food Sci. Emerg. Tech., 2009, vol. 10, pp. 643–54.

A. Guida, A.W. Nienow, and M. Barigou: Chem. Eng. Sci., 2010, vol. 65, pp. 1905–14.

A. Guida, X. Fan, D.J. Parker, A.W. Nienow, and M. Barigou: Chem. Eng. Res. Des., 2009, vol. 87, pp. 421–29.

K.E. Cole, K.E. Waters, D.J. Parker, S.J. Neethling, and J.J. Cilliers: Chem. Eng. Sci., 2010, vol. 65, pp. 1887–90.

R.D. Wilman, S. Blackburn, D.M. Benton, P.A. McNeill, and D.J. Parker: Powder Tech., 1999, vol. 103, pp. 220–29.

K.E. Waters, N.A. Rowson, X. Fan, D.J. Parker, and J.J. Cilliers: Min. Eng., 2008, vol. 21, pp. 877–82.

W.D. Griffiths, Y. Beshay, D.J. Parker, and X. Fan: J. Mater. Sci., 2008, vol. 43, pp. 6853–56.

W.D. Griffiths, D.J. Parker, X. Fan, andM. Hausard: Mater. Sci. Technol., 2010, vol. 26, pp. 528–33.

X. Fan, D.J. Parker, and M.D. Smith: Nucl. Instr. Meth., Phys. Res. A, 2006, vol. 558, pp. 542–46.

X. Fan, D.J. Parker, and M.D. Smith: Nucl. Instr. Meth., Phys. Res. A, 2006, vol. 562, pp. 345–50.

D. Parker, R. Forster, P. Fowles, and P. Takhar: Nucl. Instr. Meth. Phys. Res. A, 2002, vol. 477, pp. 540–45.

S. Brown, D.L. Bailey, K. Willowson, and C. Baldock: Appl. Radiat. Isot., 2008, vol. 66, pp. 1206–12.

Z. Yang, P.J. Fryer, S. Bakalis, X. Fan, D.J. Parker, and J.P.K. Seville: Nucl. Instr. Meth. Phys. A, 2007, vol. 577, pp. 585–94.

Z. Yang, D.J. Parker, P.J. Fryer, S. Bakalis, and X. Fan: Nucl. Instr. Meth. Phys., A, 2006, vol. 564, pp. 332–38.

Acknowledgments

The authors would like to thank Beshay Steel of Egypt for the provision of funds to enable the work to be carried out.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 27, 2011.

Rights and permissions

About this article

Cite this article

Griffiths, W.D., Beshay, Y., Caden, A.J. et al. The Use of Positron Emission Particle Tracking (PEPT) to Study the Movement of Inclusions in Low-Melting-Point Alloy Castings. Metall Mater Trans B 43, 370–378 (2012). https://doi.org/10.1007/s11663-011-9596-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9596-0