Abstract

The boundary-fixing method, by which the moving-boundary problem is reduced into the fixedboundary problem, has been applied to the numerical simulation of the molten-pool formation during the laser surface-melting process. A mathematical formulation and corresponding calculation scheme are developed for a model based on transient three-dimensional heat conduction with a moving solid-liquid interface. By the use of the boundary-fixing method, the heat balance at the solid-liquid interface is rigorously treated in the present numerical simulation. When the steady state is reached, the resulting molten pool is obtained without undulation in shape. The calculated results, based on an Al-32.7 wt pct Cu eutectic alloy, are discussed and compared with experimental data.

Similar content being viewed by others

Abbreviations

- a :

-

beam radius (defined as the radial distance at which the power density falls to 1/e of the central value) (m)

- B(θ, φ):

-

shape function of the outer boundary within the heat-affected region (m)

- d :

-

maximum depth of the molten pool (m)

- D :

-

distance between the origin of the spherical coordinate system and the center of the laser beam (m)

- F(θ, φ, t):

-

shape function of the solid-liquid interface (m)

- g(x):

-

shape function of the solidification front (m)

- h :

-

surface heat-transfer coefficient (W/m2/K)

- H :

-

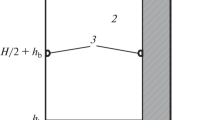

height from the bottom of the laser trace (m)

- K :

-

thermal conductivity (W/m/K)

- L :

-

latent heat (J/m3)

- N η :

-

number of nodal points in the η direction

- N ξ :

-

number of nodal points in the ξ direction

- N θ :

-

number of nodal points in the θ direction

- N φ :

-

number of nodal points in the φ direction

- P :

-

total incident power in the laser beam (W)

- q :

-

power-density distribution in the laser beam (W/m2)

- r :

-

radial coordinate (m)

- t :

-

time (s)

- T :

-

temperature (K)

- T a :

-

ambient temperature (K)

- T B :

-

temperature on the outer boundary of the heat-affected region (K)

- T eu :

-

eutectic temperature (K)

- T f :

-

temperature at the solid-liquid interface, equal to T eu (K)

- T i :

-

initial temperature of the substrate (K)

- T v :

-

vaporization temperature (K)

- U :

-

beam travel velocity (m/s)

- V s :

-

local solidification rate (m/s)

- w :

-

maximum width of the molten pool (m)

- x, y, and z :

-

spatial coordinates (m)

- α :

-

thermal diffusivity (m2/s)

- β :

-

surface absorptivity (—)

- Δt :

-

time step for calculation (s)

- Δt F :

-

time step defined by Eq. [39] (s)

- Δt L :

-

time step defined by Eq. [37] (s)

- Δt s :

-

time step defined by Eq. [38] (s)

- Δη :

-

spatial increment in the η direction, equal to 1/N η (—)

- Δξ :

-

spatial increment in the ξ direction, equal to 1/N ξ (—)

- Δθ :

-

spatial increment in the θ direction, equal to π/(N θ−1) (radians)

- Δφ :

-

spatial increment in the φ direction, equal to π/(2N φ −1) (radians)

- ɛ :

-

surface emissivity, equal to 1 - β, (—)

- η :

-

independent variable (Eq. [13]) (—)

- θ :

-

angle in spherical coordinate (radians)

- θ o :

-

reference angle, equal to π (radians)

- λ :

-

interlamellar spacing (m)

- ξ :

-

independent variable (Eq. [14]) (—)

- σ :

-

Stefan-Boltzmann constant, equal to 5.67·10−8 (W/m2/K4)

- φ :

-

angle in spherical coordinate (radians)

- φ o :

-

reference angle equal to π/2 (radians)

- ϕ :

-

angle between the vectors V s and U (radians)

- L :

-

liquid region

- S :

-

solid region

- O :

-

reference quantity, average of those of the liquid and solid regions

- *:

-

dimensionless quantity

- i, j, k, and l :

-

nodal-point indices in the η, ξ, θ, and φ directions, respectively

References

W.M. Steen: Laser Material Processing, Springer-Verlag, London, 1994, pp. 187–92.

M. Zimmermann, M. Carrard, and W. Kurz: Acta Metall., 1989, vol. 37, pp. 3305–13.

Y. Nakano, K. Nishimoto, W.P. Zhang, and Y. Tamura: Q. J. JWS, 1991, vol. 9, pp. 122–28 (in Japanese).

W. Kurz and R. Trivedi: Mater. Sci. Eng., 1994, vols. A179–A180, pp. 46–51.

W. Kurz, B. Giovanola, and R. Trivedi: Acta Metall., 1986, vol. 34, pp. 823–30.

D.C. Baxter: J. Heat Transfer. Trans. ASME, 1962, vol. 84, pp. 317–26.

K. Katayama and M. Hattori: Trans. Jpn. Soc. Mech. Eng., 1974, vol. 40, pp. 1404–11.

N. Shamsundar and E.M. Sparrow: J. Heat Transfer. Trans. ASME, 1975, vol. 97, pp. 333–40.

A.B. Crowley: Int. J. Heat Mass Transfer, 1978, vol. 21, pp. 215–19.

M. Paolini, G. Sacchi, and C. Verdi: Int. J. Numer. Meth. Eng., 1988, vol. 26, pp. 1989–2007.

S. Kou, S. Hsu, and R. Mehrabian: Metall. Trans. B, 1981, vol. 12B, pp. 33–45.

K.V. Rama Rao and J.A. Sekhar: Acta Metall., 1987, vol. 35, pp. 81–87.

A.F.A. Hoadley, M. Rappaz, and M. Zimmermann: Metall. Trans. B, 1991, vol. 22B, pp. 101–09.

J.L. Duda, F.M. Michael, H.N. Robert, and J.S. Vrentas: Int. J. Heat Mass Transfer, 1975, vol. 18, pp. 901–10.

T. Saitoh: J. Heat Transfer: Trans. ASME, 1978, vol. 100, pp. 294–99.

D. Rosenthal: Trans. ASME, 1946, vol. 68, pp. 849–66.

C.F. Gerald and P.O. Wheatley: Applied Numerical Analysis, Addison-Wesley Longman, Reading, MA, (1991), pp. 455–59.

P.J. Roache: Computational Fluid Dynamics, Hermosa Pub. Inc., Albuquerque, NM, 1976, p. 97 (Japanese translation).

T.B. Massalski: Binary Alloy Phase Diagrams, ASM, Metals Park, OH, 1986, vol. 1, pp. 103–08.

L.F. Mondolfo: Aluminum Alloys: Structure and Properties, 1st ed., Butterworth and Co., London, 1976, p. 56.

M.H. Burden and H. Jones: J. Inst. Met., 1970, vol. 98, pp. 249–52.

M. Gündüz and J.D. Hunt: Acta Metall., 1985, vol. 33, pp. 1651–72.

A. Frenk, A.F.A. Hoadley, and J.-D. Wagnière: Metall. Trans. B, 1991, vol. 22B, pp. 139–41.

A.M. Prokhorov, V.I. Konov, I. Ursu, and I.N. MihĂilescu: Laser Heating of Metals, Adam Hilger, Bristol, 1990, p. 209.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Takeshita, K., Matsunawa, A. Numerical simulation of the molten-pool formation during the laser surface-melting process. Metall Mater Trans B 32, 949–959 (2001). https://doi.org/10.1007/s11663-001-0081-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0081-z