Abstract

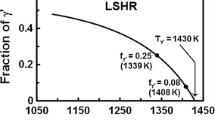

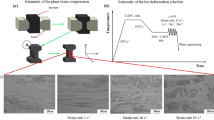

The radial temperature gradient developed via direct-resistance heating of round-bar hot-torsion specimens in a Gleeble® machine and its effect on the interpretation of plastic-flow behavior were established using a suite of experimental, analytical, and numerical-simulation tools. Observations of the microstructure variation developed within a γ′-strengthened nickel-base superalloy were used to infer the temperature gradient as well as differences between the temperature at the outer diameter and that indicated by thermocouples welded to the surface. At temperatures of the order of 1375 K (1102 °C), the radial variation of temperature was typically ~20 K (~20 °C). Such variations were in agreement with an analytical heat-conduction model based on the balance of input thermal energy and radiation heat loss at the free surface. Using a constitutive model for LSHR, the effect of the radial temperature gradient on plastic flow during hot torsion was assessed via numerical integration of the torque as a function of radial position for such cases as well as that corresponding to a uniformly-heated sample. These calculations revealed that the torque generated in the non-uniform case is almost identical to that developed in a sample uniformly preheated to a temperature corresponding to that experienced at a fractional radial location of 0.8 in the former case.

Similar content being viewed by others

References

G.E. Dieter, H.A. Kuhn, and S.L. Semiatin, eds.: Handbook of Workability and Process Design, ASM International, Materials Park, OH, 2003.

S.L. Semiatin and J.J. Jonas, Formability and Workability of Metals: Plastic Instability and Flow Localization, ASM International, Materials Park, OH, 1984.

S.L. Semiatin, N. Frey, N.D. Walker, and J.J. Jonas: Acta Metall., 1986, vol. 34, pp. 167-176.

P.D. Nicolaou, R.E. Bailey, and S.L. Semiatin: in Handbook of Workability and Process Design, G.E. Dieter, H.A. Kuhn, and S.L. Semiatin, eds., ASM International, Materials Park, OH, 2003, pp. 68–85.

H.G. Suzuki and H. Fujii: ISIJ Inter., 1991, vol. 31, pp. 814-819.

H.G. Suzuki and D. Eylon: ISIJ Inter., 1993, vol. 33, pp. 1270-1274.

H.G. Suzuki and D. Eylon: Mater. Sci. Eng. A, 1998, vol. A243, pp. 126-133.

F.F. Noecker and J.N. DuPont: Welding Journal, 2009, vol. 88 (1), pp. 7-20.

S. Shi, J.C. Lippold, and J. Ramirez: Welding Journal, 2010, vol. 89 (10), pp. 210-217.

S.S. Babu, J. Livingston, and J.C. Lippold: Metall. Mater. Trans. A, 2013, vol. 44, pp. 3577-3591.

S.G.R. Brown, J.D. James, and J.A. Spittle: Modelling Simul. Mater. Sci. Eng., 1997, vol. 5, pp. 539-548.

S.D. Norris and I. Wilson: Modelling Simul. Mater. Sci. Eng., 1999, vol. 7, pp. 297-309.

D.R. Forrest and M.F. Sinfield: Report NSWCCD-61-TR-2008/02, Naval Surface Warfare Center Carderock Division, West Bethesda, MD, 2008.

E. Kardoulaki, J. Lin, D. Balint, and D. Farrugia: J. Strain Analysis, 2014, vol. 49, pp. 521-532.

B.H. Peterson: Ph.D. Thesis, Ohio State University, Columbus, OH, 2008 (https://etd.ohiolink.edu/ap/10?0::NO:10:P10_ACCESSION_NUM:osu1218488816).

C. Zhang, M. Bellet, M. Bobadilla, H. Shen, and B. Liu: Metall. Mater. Trans. A, 2011, vol. 41A, pp. 2304-2317.

C. Zhang, M. Bellet, M. Bobadilla, H. Shen, and B. Liu: Inverse Problems in Sci. Eng., 2011, vol. 19, pp. 485-508.

C.J. Bennett, S.B. Leen, E.J. Williams, P.H. Shipway, and T.H. Hyde: Computational Mater. Sci., 2010, vol. 50, pp. 125-137.

S.L. Semiatin, D.W. Mahaffey, D.J. Tung, W. Zhang, and O.N. Senkov: Metal. Mater. Trans. A, 2017, vol. 48A, pp. 1864-1884.

J. Gayda, T.P. Gabb, and P.T. Kantzos: in Superalloys 2004, K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, and S. Walston, eds., TMS, Warrendale, PA, 2004, pp. 323–30.

S.L. Semiatin, K. E. McClary, A.D. Rollett, C.G. Roberts, E.J. Payton, F. Zhang, and T.P. Gabb: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 1649-1661.

S.L. Semiatin, K. E. McClary, A.D. Rollett, C.G. Roberts, E.J. Payton, F. Zhang, and T.P. Gabb: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2778-2798.

S.L. Semiatin, J.M. Shank, A.R. Shiveley, W.M. Saurber, E.F. Gaussa, and A.L. Pilchak: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 6231-6251.

S.L. Semiatin, S-L. Kim, F. Zhang, and J.S. Tiley: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 1715-1730.

H.S. Carslaw and J.C. Jaeger: Conduction of Heat in Solids, Oxford University Press, London, 1959, Chapter VII.

S.I. Oh, S.L. Semiatin, and J.J. Jonas: Metall. Trans. A, 1992, vol. 23A, pp. 963-975.

S.L. Semiatin, J.M. Shank, W.M. Saurber, A.L. Pilchak, D.L. Ballard, F. Zhang, and B. Gleeson: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 962-979.

E.J. Payton: PhD Dissertation, The Ohio State University, Columbus, OH, 2009, Chapter 7.

Acknowledgments

This work was conducted as part of the in-house research of the Metals Branch of the Air Force Research Laboratory’s Materials and Manufacturing Directorate. Technical discussions with S.S. Babu (University of Tennessee, Knoxville) are appreciated. The yeoman assistance of P.N. Fagin, J.O. Brown, and Z.A. Partlow in conducting the experiments is also gratefully acknowledged. Two of the authors were supported under the auspices of contracts FA8650-14-2-5800 (NCL) and FA8650-15-D-5230 (ONS).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 15, 2017.

Rights and permissions

About this article

Cite this article

Semiatin, S.L., Mahaffey, D.W., Levkulich, N.C. et al. The Radial Temperature Gradient in the Gleeble® Hot-Torsion Test and Its Effect on the Interpretation of Plastic-Flow Behavior. Metall Mater Trans A 48, 5357–5367 (2017). https://doi.org/10.1007/s11661-017-4296-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4296-2