Abstract

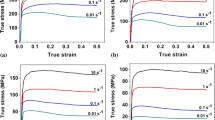

Recently, duplex stainless steels (DSSs) are being increasingly employed in chemical, petro-chemical, nuclear, and energy industries due to the excellent combination of high strength and corrosion resistance. Better understanding of deformation behavior and microstructure evolution of the material under hot working process is significant for achieving desired mechanical properties. In this work, plastic flow curves and microstructure development of the DSS grade 2507 were investigated. Cylindrical specimens were subjected to hot compression tests for different elevated temperatures and strain rates by a deformation dilatometer. It was found that stress–strain responses of the examined steel strongly depended on the forming rate and temperature. The flow stresses increased with higher strain rates and lower temperatures. Subsequently, predictions of the obtained stress–strain curves were done according to the Zener–Hollomon equation. Determination of material parameters for the constitutive model was presented. It was shown that the calculated flow curves agreed well with the experimental results. Additionally, metallographic examinations of hot compressed samples were performed by optical microscope using color tint etching. Area based phase fractions of the existing phases were determined for each forming condition. Hardness of the specimens was measured and discussed with the resulted microstructures. The proposed flow stress model can be used to design and optimize manufacturing process at elevated temperatures for the DSS.

Similar content being viewed by others

References

C.U. Jeong, W. Woo, J.Y. Choi, S.H. Choi: Acta Materialia, 2014, vol. 67, pp. 21–31.

E.Y. Guo, H.X. Xie, S.S. Singh, A. Kirubanandham, T. Jing, N. Chawla: Mater. Sci. Eng. A, 2014, vol. 575, pp. 41–47.

S. Spigarelli, M.E. Mehtedi, P. Ricci, C. Mapelli: Mater. Sci. Eng. A, 2010, vol. 527, pp. 4218–4228.

D.N. Zou, K. Wu, Y. Han, W. Zhang, B. Cheng, G.J. Qiao: Mater. Design, 2013, vol. 51, pp. 975–982.

A. Momeni, K. Dehghani, M.C. Poletti: Mater. Chem. Physics, 2013, vol. 139, pp. 747–755.

Y. Han, G.J. Qiao, J.P. Sun, D.N. Zou: Comput. Mater. Sci., 2013, vol. 67, pp. 93–103.

Y. Han, D.N. Zou, Z. Chen, G.W. Fan, W. Zhang: Mater. Characterization, 2011, vol. 62, pp. 198–203.

G.B. Wei, X.D. Peng, A. Hadadzadeh, Y. Mahmoodkhani, W.D. Xie, Y. Yang, M.A. Wells: Mech. Mater., 2015, vol. 89, pp. 241–253.

H. Farnoush, A. Momeni, K. Dehghani, J. Aghazadeh Mohandesi, H. Keshmiri: Mater. Design, 2010, vol. 31, pp. 220–226.

F.C. Ren, J. Chen, F. Chen: Trans. Nonferrous Metals Society of China, 2014, vol. 24, pp. 1407–1413.

A. Momeni and K. Dehghani: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1448–1454.

Y.H. Yang and B. Yan: Mater. Sci. and Eng. A, 2013, vol. 579, pp. 194–201.

F. Tehovnik, B. Arzenšek, B. Arh, D. Skobir, B. Pirnar, B. Žužek: Mater. Tech., 2011, vol. 45, pp. 339–345.

E. Farabi, A.Z. Hanzaki, M.H. Pishbin, M. Moallemi: Mater. Sci. Eng. A, 2015, vol. 641, pp. 360–368.

J. Porntadawit, V. Uthaisangsuk, P. Choungthong: Mater. Sci. Eng. A, 2014, vol. 599, pp. 212–222.

G.B. Wei, X.D. Peng, A. Hadadzadeh, Y. Mahmoodkhani, W.D. Xie, Y. Yang, M.A. Wells: Mech. Mater., 2015, vol. 89, pp. 241–253.

Y. Han, G.W. Liu, D.N. Zou, R. Liu, G.J. Qiao: Mater. Sci. Eng. A, 2013, vol. 565, pp. 342–350.

A. Mohamadizadeh, A. Zarei–Hanzaki, H.R. Abedi: Mech. Mater., 2016, vol. 95, pp. 60–70.

L.Ch. Yang, Y.T. Pan, I.G. Chen, D.Y. Lin: Metals, 2015, vol. 5, pp. 1717–1731.

F.C. Campbell: Elements of Metallurgy and Engineering Alloys, ASM International, Ohio, 2008.

W. Bleck: Material Characterization, 2nd ed., Verlag Mainz, Aachen, p. 92.

A.U. Sulijoadikusumo, O.W. Dillon: Metallurgical effects at high strain rates, Plenum Press, New York–London, 1973, pp. 501–517.

G.E. Dieter, H.A. Kuhn, S.L. Semiatin: Handbook of Workability and Process Design, ASM International, Materials Park, Ohio, OH, 2003, pp. 17–19.

J.Q. Zhang, H.S. Di, K. Mao: Mater. Sci. Eng. A, 2013, vol. 587, pp. 110–122.

R.E. Schramn, R.P. Reed: Metall. Trans. A, 1975, vol. 6, pp. 1345–1351.

J. Charles: In Proceedings of Conference of Duplex Stainless Steel’ 91, Beaune, Les editions de physique, 1991, pp. 3–48.

Acknowledgments

The authors would like to acknowledge the Office of the Higher Education Commission, Thailand Research Fund (TRF), and King Mongkut’s University of Technology Thonburi (KMUTT) for financial support (TRG5880258).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 20, 2015.

Rights and permissions

About this article

Cite this article

Kingklang, S., Uthaisangsuk, V. Investigation of Hot Deformation Behavior of Duplex Stainless Steel Grade 2507. Metall Mater Trans A 48, 95–108 (2017). https://doi.org/10.1007/s11661-016-3829-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3829-4