Abstract

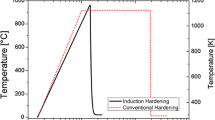

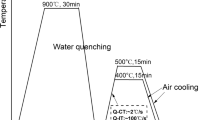

An induction heat treatment is favorable compared to a conventional one mainly due to significant time and cost savings. Therefore, in this study, the microstructure property relationships during induction and conventional heat treatment of a heat treatable steel 42CrMo4 is investigated. The yield strength and hardness is slightly higher for the conventionally heat-treated steel, whereas the induction heat-treated condition exhibits a roughly 30 J/cm2 higher impact energy. In a previous investigation of the authors, it has been proved that the difference in yield strength originates from the smaller block size of the conventionally heat-treated steel, which was already present after hardening. In the present work, it can be shown that during tempering the martensitic blocks become equi-axed ferrite grains due to recrystallization as revealed by electron back scatter diffraction. Nevertheless, a larger grain size usually is less favorable for the impact toughness of steels. Therefore, another mechanism is responsible for the higher impact energy of the induction hardened and tempered steel. With the aid of transmission electron microscopy a finer distribution of cementite was observed in the induction heat-treated samples. The delay of recovery is the reason for the presence of finer cementite in case of the induction heat-treated steel. Here, the higher heating rates and shorter process times reduce the annihilation of dislocation and as a consequence provide more nucleation sites for precipitation of cementite during tempering. From the obtained experimental results, it is believed that the finer distribution of carbides causes the observed higher impact toughness.

Similar content being viewed by others

References

1. S. T. Ahn, D. S. Kim, and W. J. Nam, J. Mater. Process. Technol. 160, 54 (2005).

2. C. Revilla, B. López, and J. M. Rodriguez-Ibabe, Mater. Des. 62, 296 (2014).

J. M. Mendizabal, L., Rodriguez-Ibabe, Mater. Sci. Technol. (2005), pp. 77–84.

C. Revilla, P. Uranga, B. López, and J.M. Rodriguez-Ibabe, in AIST Steel Prop. Appl. Conf. Proc.—Comb. with MS T’12, Mater. Sci. Technol. 2012 (2012), pp. 267–74.

5. H. Leitner, D. Caliskanoglu, and H. Clemens, BHM Berg- und Hüttenmännische Monatshefte 149, 172 (2004).

6. S. Sackl, H. Leitner, M. Zuber, H. Clemens, and S. Primig, Metall. Mater. Trans. A 45, 5657 (2014).

K. C. Smith, J. P. Wise, and G. Krauss, Prog. Heat Treat. Surf. Eng. (2000), pp. 379–86.

8. J. Grosch, B. Kocjancic, and G. Reichelt, Haerterei Technsiche Mitteilungen 39, 199 (1984).

Krauss, G. (2012). Phase Transform Steels (pp. 126–150). Elsevier, Amsterdam

10. G. Speich and W. Leslie, Metall. Trans. A 3, 1043 (1972).

11. R. C. Thomson and M. K. Miller, Appl. Surf. Sci. 94-95, 313 (1996).

M.K. Miller, P.A. Beaven, and G.D.W. Smith, Metall. Trans. A 12, 1197 (1981).

E. R. Parker, Metall. Trans. A, 8, 1025–1042 (1977).

14. H. Bhadeshia and R. Honeycombe, Steels Microstructure and Properties, 3rd ed. (Butterworth-Heinemann (Elsevier), Oxford, 2006).

15. K. Hanawa and T. Mimura, Metall. Trans. A 15A, 1147 (1984).

16. D. Dengel, Haerterei Technsiche Mitteilungen 39, 182 (1984).

17. S. Primig and H. Leitner, Thermochim. Acta 526, 111 (2011).

18. T. Furuhara, K. Kobayashi, and T. Maki, ISIJ Int. 44, 1937 (2004).

19. R. N. Caron and G. Krauss, Metall. Trans. 3, 2381 (1972).

20. M. Hayakawa, S. Matsuoka, K. Tsuzaki, H. Hanada, and M. Sugisaki, Scr. Mater. 47, 655 (2002).

21. S. Xing, Z. Chen, Y. Ma, and H. Li, J. Iron Steel Res. Int. 19, 43 (2012).

22. J. Wu, P. J. Wray, C. I. Garcia, M. Hua, and A. J. Deardo, ISIJ Int. 45, 254 (2005).

23. F. Foroozmehr, A. Najafizadeh, and A. Shafyei, Mater. Sci. Eng. A 528, 5754 (2011).

24. L. S. Darken, Trans. AIME 175, 184 (1948).

25. A. A. Zhukov, Met. Sci. Heat Treat. 18, 1070 (1976).

26. J. Verhoeven, J. Mater. Eng. Perform. 9, 286 (2000).

G. Krauss, Metall. Mater. Trans. B 34, 781 (2003).

Acknowledgments

The financial support by the Austrian Federal Ministry of Economy, Family and Youth and the National Foundation for Research, Technology and Development is gratefully acknowledged. The authors want to thank Tomasz Wojcik for his help regarding the TEM investigations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 22, 2016.

Rights and permissions

About this article

Cite this article

Sackl, S., Zuber, M., Clemens, H. et al. Induction Tempering vs Conventional Tempering of a Heat-Treatable Steel. Metall Mater Trans A 47, 3694–3702 (2016). https://doi.org/10.1007/s11661-016-3534-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3534-3