Abstract

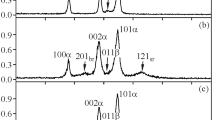

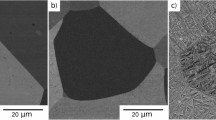

Ultrasonic measurements have been carried out in Ti-10V-4.5Fe-1.5Al β-titanium alloy specimens subjected to β annealing at 1173 K (900 °C) for 1 hour followed by heat treatment in the temperature range of 823 K to 1173 K (550 °C to 900 °C) at an interval of 50 K (50 °C) for 1 hour, followed by water quenching. Ultrasonic parameters such as ultrasonic longitudinal wave velocity, ultrasonic shear wave velocity, shear anisotropy parameter, ultrasonic attenuation, and normalized nonlinear ultrasonic parameter have been correlated with various microstructural changes to understand the interaction of the propagating ultrasonic wave with microstructural features in the alloy. Simulation studies using JMatPro® software and X-ray diffraction measurements have been carried out to estimate the α-phase volume fraction in the specimens heat treated below the β-transus temperature (BTT). It is found that the α-phase (HCP) volume fraction increases from 0 to 52 pct, with decrease in the temperature from 1073 K to 823 K (800 °C to 550 °C). Ultrasonic longitudinal and shear wave velocities are found to increase with decrease in the heat treatment temperature below the BTT, and they exhibited linear relationships with the α-phase volume fraction. Thickness-independent ultrasonic parameters, Poisson’s ratio, and the shear anisotropy parameter exhibited the opposite behavior, i.e., decrease with increase in the α-phase consequent to decrease in the heat treatment temperature from 1073 K to 823 K (800 °C to 550 °C). Ultrasonic attenuation is found to decrease from 0.7 dB/mm for the β-annealed specimen to 0.23 dB/mm in the specimen heat treated at 823 K (550 °C) due to the combined effect of the decrease in the β-phase (BCC) with higher damping characteristics and the reduction in scattering due to randomization of β grains with the precipitation of α-phase. Normalized nonlinear ultrasonic parameter is found to increase with increase in the α-phase volume fraction due to increased interfacial strain. For the first time, quantitative correlations established between various ultrasonic parameters and the volume fraction of α-phase in a β-titanium alloy are reported in the present paper. The established correlations are useful for estimation of volume fraction of α-phase in heat-treated β-titanium alloy, by nondestructive ultrasonic measurements.

Similar content being viewed by others

References

S. Ankem and C. A. Greene: Mater. Sci. Eng. A, 1999, vol. 263, pp. 127–31.

R.R. Boyer, G.E. Welsch, and E.W. Collings, eds.: Materials Properties Handbook Titanium Alloys, ASM International, Materials Park, OH, 1994, pp. 483–636.

A. Kumar, T. Jayakumar, B. Raj, and D. Banerjee: Phil. Mag., 2008, vol. 88, pp. 327–38.

Y. T. Lee and G. Welsch: Mater. Sci. Eng. A, 1990, vol. 128, pp. 77–89.

T. Ozaki, H. Matsumoto, S. Watanabe, and S. Hanada: Mater. Trans., 2004, vol. 45, pp. 2776–79.

A. Kumar, T. Jayakumar, and K. K. Ray: Mater. Sci. Eng. A, 2003, vol. 360, pp. 58–64.

S. C. Lee and J. M. Suen: Metall. Trans. A, 1989 vol. 20A, pp. 2399–407.

D. C. Hurley, D. Balzar, P. T. Purtscher, and K. W. Hollman: J. Appl. Phys., 1998, vol. 83, pp. 4584–88.

A. Kumar, K. Laha, T. Jayakumar, K. B. Rao, and B. Raj: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1617–27.

K. V Rajkumar, A. Kumar, T. Jayakumar, B. Raj, and K. K. Ray: Metall. Mater. Trans. A, 2010, vol. 38A, pp. 236–43.

A. Viswanath, B. P. C. Rao, S. Mahadevan, T. Jayakumar, and B. Raj: J. Mater. Sci., 2010, vol. 45, pp. 6719–26.

J. H. Cantrell and W. T. Yost: J. Appl. Phys., 1997, vol. 81, pp. 2957–62.

J. Frouin, S. Sathish, T. E. Matikas, and J. K. Na: J. Mater. Res., 1999, vol. 14, pp. 1295–98.

A. Viswanath, B. Purna Chandra Rao, S. Mahadevan, P. Parameswaran, T. Jayakumar, and B. Raj: J. Mater. Process. Technol., 2011, vol. 211, pp. 538–44.

S. Baby, B. Nagaraja Kowmudi, C. M. Omprakash, D. V. V. Satyanarayana, K. Balasubramaniam, and V. Kumar: Scripta Mater., 2008, vol. 59, pp. 818–21.

A. Kumar, U. Rabe, and W. Arnold: Jpn. J. Appl. Phys., 2008, vol. 47, pp. 6077–80.

I. Weiss and S. L. Semiatin: Mater. Sci. Eng. A, 1998, vol. 243, pp. 46–65.

A. K. Singh, A. Bhattacharjee, and A. K. Gogia: Mater. Sci. Eng. A, 1999, vol. 270, pp. 225–30.

Z. Guo, N. Saunders, J. P. Schillé, and A. P. Miodownik: Mater. Sci. Eng. A, 2009, vol. 499, pp. 7–13.

N. Saunders, X. Li, A.P. Miodownik, and J. Schille: Proc. 10th World Conf. Titan., 2005, vol. 1397, Hamburg.

J. Sun, Q. Yao, H. Xing, and W. Y. Guo: J. Phys. Condens. Matter, 2007, vol. 19, pp. 486215–22.

Y. Mantani, Y. Takemoto, M. Hida, A. Sakakibara, and M. Tajima: Mater. Trans., 2004, vol. 45, pp. 1629–34.

A. Kumar, T. Jayakumar, B. Raj, and K. K. Ray: Acta Mater., 2003, vol. 51, pp. 2417–26.

C. Rhodes and J. Williams: Metall. Trans. A, 1975, vol. 6, pp. 2103–14.

T. Furuhara, T. Makino, Y. Idei, H. Ishigaki, A. Takada, and A. Maki: Mater. Trans., 1998, vol. 39, pp. 31–39.

P.A. Russo, J.R. Wood, R.B. Bhagat, and S.L. Opet: in Beta Titanium alloys in the 1990’s, D. Eylon, R.R. Boyer, and D.A. Koss, eds., TMS, Pennsylvania, 1993, pp. 361–74.

Acknowledgments

The authors thank Dr. P.R. Vasudeva Rao, Director, Indira Gandhi Centre for Atomic Research (IGCAR), Kalpakkam for his constant encouragement and support. They also thank Prof. Dipankar Banerjee, IISc, Bangalore (Former Director, Defence Metallurgical Research Laboratory (DMRL), Hyderabad), Dr Amol A Gokhale, Director DMRL, Hyderabad, and Dr. A. Bhattacharjee, Scientist, DMRL, Hyderabad for providing the β-titanium alloy material. The authors thank Dr. S. Murugesan, Scientific Officer, Physical Metallurgy Group, Indira Gandhi Centre for Atomic Research, Kalpakkam, for carrying out XRD measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 7, 2014.

Rights and permissions

About this article

Cite this article

Viswanath, A., Kumar, A., Jayakumar, T. et al. Ultrasonic Characterization of Microstructural Changes in Ti-10V-4.5Fe-1.5Al β-Titanium Alloy. Metall Mater Trans A 46, 3393–3405 (2015). https://doi.org/10.1007/s11661-015-2979-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2979-0