Abstract

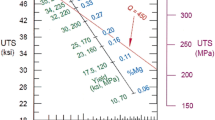

High-temperature tensile and low-cycle fatigue tests were performed to assess the influence of micro-additions of Ti, V, and Zr on the improvement of the Al-7Si-1Cu-0.5Mg (wt pct) alloy in the as-cast condition. Addition of transition metals led to modification of microstructure where in addition to conventional phases present in the Al-7Si-1Cu-0.5Mg base, new thermally stable micro-sized Zr-Ti-V-rich phases Al21.4Si4.1Ti3.5VZr3.9, Al6.7Si1.2TiZr1.8, Al2.8Si3.8V1.6Zr, and Al5.1Si35.4Ti1.6Zr5.7Fe were formed. The tensile tests showed that with increasing test temperature from 298 K to 673 K (25 °C to 400 °C), the yield stress and tensile strength of the present studied alloy decreased from 161 to 84 MPa and from 261 to 102 MPa, respectively. Also, the studied alloy exhibited 18, 12, and 5 pct higher tensile strength than the alloy A356, 354 and existing Al-Si-Cu-Mg alloy modified with additions of Zr, Ti, and Ni, respectively. The fatigue life of the studied alloy was substantially longer than those of the reference alloys A356 and the same Al-7Si-1Cu-0.5Mg base with minor additions of V, Zr, and Ti in the T6 condition. Fractographic analysis after tensile tests revealed that at the lower temperature up to 473 K (200 °C), the cleavage-type brittle fracture for the precipitates and ductile fracture for the matrix were dominant while at higher temperature fully ductile-type fracture with debonding and pull-out of cracked particles was identified. It is believed that the intermetallic precipitates containing Zr, Ti, and V improve the alloy performance at increased temperatures.

Similar content being viewed by others

References

R. Tucker: Met. Finish., 2013, vol. 111, pp. 23–25.

Aluminum Promises Greater Fuel-Efficiency: Metallurgy, Mater. Today, 2002, vol. 5, p. 12.

R. Tucker: Met. Finish., 2013, vol. 111, pp. 31–33.

G. Sha, H. Möller, W.E. Stumpf, J.H. Xia and G. Goven: Acta Mater., 2012, vol. 60, pp. 692–701.

M.F. Ibrahim, E. Samuel, A.M. Samuel, A.M. Al–Ahmari and F.H. Samuel: Mater. Des., 2011, vol. 32, pp. 3900–3910.

O. Elsebaie, A.M. Mohamed, A.M. Samuel and F.H. Samuel: Mater. Des., 2011, vol. 32, pp. 3205–3220.

J. Hernandez–Sandoval, G.H. Garza–Elizondo, A.M. Samuel, S. Valtiierra and F.H. Samuel: Mater. Des., 2014, vol. 58, pp. 89–101.

Y. Sui, Q. Wang, G. Wang and T. Liu: J. Alloys Compd., 2015, vol. 622, pp. 572–579.

S.K. Chaudhury and D. Apelian: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 763–778.

P. Sepehband, R. Mahmudi and F. Khomamizadeh: Scripta Mater., 2005, vol. 52, pp. 253–257.

R. Mahmudi, P. Sepehrband and H.M. Ghasemi: Mater. Lett., 2006, vol. 60, pp. 2606–2610.

W. Kasprzak, D. Emadi, M. Sahoo and M. Aniolek: Mater. Sci. Forum., 2009, vol. 618–619, pp. 595–600.

W. Kasprzak, D.L. Chen and S.K. Shaha: J. Mater. Eng. Perform., 2013, vol. 22, pp. 1838–1847.

W. Kasprzak, B.S. Amirkhiz and M. Niewczas: J. Alloys Compd., 2014, vol. 595, pp. 67–79.

S.K. Shaha, F. Czerwinski, W. Kasprzak and D.L. Chen: J. Alloys Compd., 2014, vol. 593, pp. 290–299.

T. Gao, X. Zhu, Q. Sun and X. Liu: J. Alloys Compd., 2013, vol. 567, pp. 82–88.

S.K. Shaha, F. Czerwinski, W. Kasprzak and D.L. Chen: Mater. Des., 2014, vol. 59, pp. 352–358.

K.L. Sahoo and B.N. Pathak: J. Mater. Process. Technol., 2009, vol. 209, pp. 798–804.

X.–G. Chen and M. Fortier: J. Mater. Process. Technol., 2010, vol. 210, pp. 1780–1786.

C. Booth–Morrison, Z. Mao, M. Diaz, D.C. Dunand, C. Wolverton and D.N. Seidman: Acta Mater., 2012, vol. 60, pp. 4740–4752.

Y. Li, Y. Yang, Y. Wu, L. Wang and X. Liu: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7132–7137.

Y. Li, Y. Yang, Y. Wu, Z. Wei and X. Liu: Mater. Sci. Eng. A, 2011, vol. 528, pp. 4427–4430.

J. H. Hollomon: Trans. AIME, 1945, vol. 162, pp. 268–290.

Y. Meng, J. Cui, Z. Zhao and Y. Zuo: J. Alloys Compd., 2013, vol. 573, pp. 102–111.

T.V. Atamanenko, D.G. Eskin, M. Sluiter and L. Katgerman: J. Alloys Compd., 2011, vol. 509, pp. 57–60.

T. Gao and X. Liu: J. Mater. Sci. Technol., 2013, vol. 29, pp. 291–296.

A.M. Mohamed, F.H. Samuel and S. Al–kahtani: Mater. Sci. Eng. A, 2013, vol. 577, pp. 64–72.

H.A. Elhadari, H.A. Patel, D.L. Chen and W. Kasprzak: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8128–8138.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman and D.L. Chen: Int. J. Fatigue, 2015, vol. 70, p. 383–394.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman and D.L. Chen: Thermochim. Acta, 2014, vol. 595, pp. 11–16.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, and D.L. Chen: Metall. Mater. Sci. Eng. A, unpublished research, 2015.

G.E. Dieter: Mechanical Metallurgy, SI Metric Edition, London, UK: McGraw–Hill Book Company, 1988, pp. 283–84.

L. Hurtalová, E. Tillová and M. Chalupová: Arch. Mech. Eng., 2012, vol. 59, pp. 385–396.

L. Lasa and J.M. Rodriguez-Ibabe: J. Mater. Sci., 2004, vol. 39, pp. 1343–1355.

M.F. Ibrahim, E. Samuel, A.M. Samuel, A.M. Al–Ahmari and F.H. Samuel: Mater. Des., 2011, vol. 32, pp. 2130–2142.

K.L. Fan, G.Q. He, X.S. Liu, B. Liu, M. She, Y.L. Yuan, Y. Yang and Q. Lu: Mater. Sci. Eng. A, 2013, vol. 586, pp. 78–85.

E.-S.Y. El-Kady, T.S. Mahmoud and M.A.-A. Sayed: Mater Sci Appl., 2011, vol. 2, pp. 390–398.

W.F. Hosford: in Mechanical Behavior of Materials, Cambridge University Press, New York, 2005, pp. 279–307.

M.S. Song, Y.Y. Kong, M.W. Ran and Y.C. She: Int. J. Fatigue, 2013, vol. 33, pp. 1600–1607.

A.R. Emami, S. Begum, D.L. Chen, T. Skszek, X.P. Niu, Y. Zhang and F. Gabbianelli: Mater. Sci. Eng. A, 2009, vol. 516, pp. 31–41.

M. Azadi and M.M. Shirazabad: Mater. Des., 2013, vol. 45, pp. 279–285.

S.K. Shaha, F. Czerwinski, D.L. Chen and W. Kasprzak: Mater. Sci. Technol., 2015, vol. 31, pp. 63–72.

H.R. Ammar, A.M. Samuel and F.H. Samuel: Int. J. Fatigue, 2008, vol. 30, pp. 1024–1035.

Q.G. Wang, P.N. Crepeau, C.J. Davidson and J.R. Griffiths: Metall. Mater. Trans. B, 2006, vol. 37, pp. 887–895.

J.Z. Zhou, S. Huang, J. Sheng, J.Z. Lu, C.D. Wang, K.M. Chen, H.Y. Ruan and H.S. Chen: Mater. Sci. Eng. A, 2012, vol. 539, pp. 360–368.

J. Schäfer and K. Albe: Scripta. Mater., 2012, vol. 66, pp. 315–317.

W.A. Curtin: Scripta Mater., 2010, vol. 63, pp. 917–920.

C.V. Singh, A.J. Mateos and D.H. Warner: Scripta Mater., 2011, vol. 64, pp. 398–401.

N.F. Mott: Nature, 1955, vol. 175, pp. 365–367.

P. Cavaliere and P.P. De Marco: Mater. Sci. Eng. A, 2007, vol. 462, pp. 206–210.

S. Spigarelli, M. Cabibbo, E. Evangelista and J. Bidulská: J. Mater. Sci., 2003, vol. 38, pp. 81–88.

Q.G. Wang: Metall. Mater. Trans. A, 2004, vol. 35, pp. 2707–2718.

C.-Y. Jeong: Mater. Trans., 2012, vol. 53, pp. 234–239.

Q.G. Wang and C.H. Caceres: Mater. Sci. Eng. A, 1997, vol. 234–236, pp. 106–109.

R.J. Asaro and Y. Kulkarni: Scripta Mater., 2008, vol. 58, pp. 389–392.

P.A. Rometsch and G.B. Schaffer: Mater. Sci. Eng. A, 2002, vol. 325, pp. 424–434.

G. Zhang, J. Zhang, B. Li and W. Cai: Mater. Sci. Eng. A, 2013, vol. 561, pp. 23–33.

Acknowledgments

The authors would like to acknowledge the financial support of the ecoENERGY Innovation Initiative ecoEII of Natural Resources Canada at CanmetMATERIALS. One of the authors (D.L. Chen) is grateful for the financial support by the Natural Sciences and Engineering Research Council of Canada (NSERC), PREA, NSERC-DAS Award, CFI, and RRC program. The authors would also like to thank Q. Li, A. Machin, J. Amankrah, and R. Churaman for their assistance in the experiments. The authors also thank Professor S. Bhole for the helpful discussion as well as P. Newcombe, G. Birsan, H. Webster, D. McFarlan, F. Benkel, M. Thomas, and D. Saleh from CanmetMATERIALS for casting experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

©Published with permission of Her Majesty the Queen in Right of Canada pertains to F. Czerwinski and W. Kasprzak.

Manuscript submitted December 22, 2014.

Rights and permissions

About this article

Cite this article

Shaha, S.K., Czerwinski, F., Kasprzak, W. et al. Improving High-Temperature Tensile and Low-Cycle Fatigue Behavior of Al-Si-Cu-Mg Alloys Through Micro-additions of Ti, V, and Zr. Metall Mater Trans A 46, 3063–3078 (2015). https://doi.org/10.1007/s11661-015-2880-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2880-x