Abstract

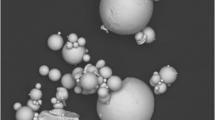

Nanocrystalline iron and oxide dispersion-strengthened (ODS) iron powders (Fe, Fe-Y2O3, and Fe-Y2O3-Ti) were prepared by mechanical milling for periods ranging from 1 to 40 hours. The as-milled powders were examined for changes in their particle sizes, crystallite sizes, hardness values, and phases present as a function of milling time. Both the particle and the crystallite sizes of all the three compositions decreased with milling time, while the hardness values of all the three powders increased with milling time because of the crystallite size refinement. At the same crystallite size, the hardness values of Fe-Y2O3 and Fe-Y2O3-Ti powders were higher than that of the Fe powders. Though, the presence of 40 nm Y2O3 could be established for 2-hour milling, such particles were not resolvable in 40-hour-milled powders. However, SAD patterns confirmed the presence of complex oxide dispersoids in the Fe-Y2O3 and Fe-Y2O3-Ti powders. The variation of hardness value with the crystallite size and as a function of the milling time can be rationalized on the basis of Hall–Petch crystallite size strengthening in combination with dispersion strengthening (in Fe-Y2O3- and Fe-Y2O3-Ti-milled powders) due to dispersoids. The observed double-positive slopes in the Hall–Petch relationship can be explained in terms of an increase in misorientation angle between the crystallites with increasing milling time due to the crystallite rotation driven by disclination dipoles.

Similar content being viewed by others

References

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1-184.

B.S. Murty and S. Ranganathan: Int. Mater. Rev., 1998, vol. 43, pp. 101-144.

C. Cayron, E. Rath, I. Chu, S. Launois: J. Nucl. Mater., 2004, vol. 335, pp. 83–102.

M.J. Alinger, G.R. Odette and D.T. Hoelzer: Acta Mater., 2009, vol. 57, pp. 392–406.

M. Ratti, D. Leuvrey, M.H. Mathon and Y de Carlon: J. Nucl. Mater., 2009, vol. 386-388, pp. 540-43.

L. Dai, Y. Liu and Z. Dong: Powder Technol., 2012, vol. 217, pp. 281-87.

E. O. Hall: Proc. Phys. Soc. B, 1951, vol. 64, pp. 747-53.

N. J. Petch: J. Iron Steel Inst. (Lond.), 1953, vol. 173, pp. 25-28.

J. Gil Sevillano, P. van Houtte and E. Aernoudt: Prog. Mater. Sci., 1981, vol. 25, pp. 69-412.

T.H. de Keijser, J.I. Langford, E.J. Mittemeijer, A.B.P. Vogels: J. Appl. Crystallogr., 1982, vol. 15, pp. 308-14.

C. Dong: J. Appl. Crystallogr., 1999, vol. 32, p. 838.

H. Sakasegawa, S. Ohtuska, S. Ukai, H. Tanigawa, M. Fujiwara, H. Ogiwara and A. Kohyama: J. Nucl. Mater., 2007, vol. 367, pp. 185-90.

J.S.C. Jang and C.C. Koch: Scripta Metall. Mater., 1990, vol. 24, pp. 1599-1604.

T.G. Nieh and J. Wadsworth: Scripta Metall. Mater., 1991, vol. 25, pp. 955-58.

K. Sulleiova, M. Besterci, and T. Kvackaj: Metal 2009, Proceedings 18th International Conference on Metallurgical and Materials, 2009, pp. 488–92.

J. Eckert, J.C. Holzer, C.E. Krill III and W.L. Johnson: J. Mater. Res., 1992, vol. 7, pp. 1980-83.

T. Volpp, E. Goring, W.M. Kusche and E. Arzt: Nanostruct. Mater., 1997, vol. 8, pp. 855-65.

M. Klimiankou, R. Lindau and A. Moslang: J. Crystal Growth, 2003, vol. 249, pp. 381–87.

S.W. Kim, T. Shobu, S. Ohtsuka, T. Kaito, M. Inoue and M. Ohnuma: Mater. Trans., 2009, vol. 50, pp. 917-21.

Y. Kimura and S. Takaki: Mater. Trans. JIM, 1995, vol. 36, pp. 289-96.

D. Tabor: The Hardness of Metals, Oxford University Press, New York, NY, 2000.

P. Le Brun, E. Gaffet, L. Proyen, and L. Delaey: Scripta Metall. Mater., 1992, vol. 26, pp. 1743–48.

H.H. Fu, D.J. Benson and M.A. Mayers: Acta Mater., 2001, vol. 49, pp. 2567-82.

M. Murayama, J.M. Howe, H. Hidaka and S. Takaki; Science, 2002, vol. 295, pp. 2433-35.

M.A. Meyers, A. Mishra and D.J. Benson, Prog. Mater. Sci., 2006, vol. 51, pp. 427-556.

M. Seefeldt, Rev. Adv. Mater. Sci., 2001, vol. 2, pp. 44-79.

J. Miyake and M.E. Fine: Acta Metallur. Mater., 1992, vol. 40, pp. 733-41.

M.F. Ashby: Metallurgical Society Conference, Gordon & Breach, New York, NY, 1968, p. 431.

D.J. Bacon, U.F. Kocks and R.O. Scattergood: Philos. Mag., 1973, vol. 28, pp. 1241-63

R. Vijay and M. Ramakrishna: International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad, India, 2012, Unpublished Research.

Acknowledgments

The authors thank Mr. G.V.R. Reddy for his help in carrying out SEM analysis. The help rendered by Dr. K. Satya Prasad, DMRL, Hyderabad for TEM examination is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 31, 2012.

Rights and permissions

About this article

Cite this article

Vijay, R., Nagini, M., Joardar, J. et al. Strengthening Mechanisms in Mechanically Milled Oxide-Dispersed Iron Powders. Metall Mater Trans A 44, 1611–1620 (2013). https://doi.org/10.1007/s11661-012-1494-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1494-9