Abstract

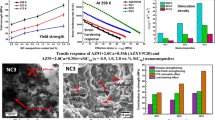

This study is aimed at understanding the function of two nitride nanoparticles regarding altering the mechanical properties of hybrid magnesium alloys in relation to nanoparticle-matrix reactivity. Nitride nanoparticles were selected for reinforcement purposes due to the affinity between magnesium and nitrogen (in parallel with the well-known magnesium-oxygen affinity). AZ91/ZK60A and AZ31/AZ91 hybrid magnesium alloys were reinforced with AlN and Si3N4 nanoparticles (respectively) using solidification processing followed by hot extrusion. Each nitride nanocomposite exhibited higher tensile strength than the corresponding monolithic hybrid alloy. However, AZ91/ZK60A/AlN exhibited slightly lower tensile ductility than AZ91/ZK60A, while AZ31/AZ91/Si3N4 exhibited higher tensile ductility than AZ31/AZ91. The formation of high strain zones (HSZs) (from particle surfaces inclusive) during tensile deformation as a significant mechanism supporting ductility enhancement was addressed. AZ91/ZK60A/AlN exhibited lower and higher compressive strength and ductility (respectively) compared to AZ91/ZK60A, while AZ31/AZ91/Si3N4 exhibited higher and unchanged compressive strength and ductility (respectively) compared to AZ31/AZ91. Nanograin formation (recrystallization) during room temperature compressive deformation (as a toughening mechanism) in relation to nanoparticle-stimulated nucleation (NSN) ability was also discussed. The beneficial (as well as comparative) effects of the respective nitride nanoparticle on each hybrid alloy are studied in this article.

Similar content being viewed by others

References

M.M. Avedesian and H. Baker (ed.): ASM Specialty Handbook: Magnesium and Magnesium Alloys, ASM International, Materials Park, OH, 1999.

Y. Morisada, H. Fujii, T. Nagaoka, and M. Fukusumi: Scripta Mater., 2006, vol. 55, pp. 1067–70.

Y. Morisada, H. Fujii, T. Nagaoka, and M. Fukusumi: Mater. Sci. Eng. A, 2006, vol. 419, pp. 344–48.

C.J. Lee, J.C. Huang, and P.J. Hsieh: Scripta Mater., 2006, vol. 54, pp. 1415–20.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta: J. Nanopart. Res., 2011, vol. 13, pp. 4855–66.

M. Paramsothy, S.F. Hassan, N. Srikanth, and M. Gupta: J. Nanosci. Nanotechnol., 2010, vol. 10, pp. 956–64.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta: Mater. Sci. Eng. A, 2011, vol. 528, pp. 6545–51.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta: J. Nanotechnol., 2011. Doi:10.1155/2011/401574.

M. De Cicco, H. Konishi, G. Cao, H.S. Choi, L.S. Turng, J.H. Perepezko, S. Kou, R. Lakes, and X. Li: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 3038–45.

H.J. Choi, J.H. Shin, B.H. Min, and D.H. Bae: Composites A, 2010, vol. 41, pp. 327–29.

H.J. Choi, J.H. Shin, and D.H. Bae: Compos. Sci. Technol., 2011, vol. 71, pp. 1699–705.

H.J. Choi, J.H. Shin, B.H. Min, J.S. Park, and D.H. Bae: J. Mater. Res., 2009, vol. 24(8), pp. 2610–16.

H.T. Liu and L.Z. Sun: Acta Mater., 2005, vol. 53, pp. 2693–701.

D.K. Ward, W.A. Curtin, and Y. Qi: Acta Mater., 2006, vol. 54, pp. 4441–51.

M. Gupta, M.O. Lai, and C.Y.H. Lim: J. Mater. Process. Technol., 2006, vol. 176, pp. 191–99.

M. Gupta, M.O. Lai, and S.C. Lim: J. Alloys Compd., 1997, vol. 260, pp. 250–55.

S.F. Hassan and M. Gupta: J. Mater. Sci., 2006, vol. 41, pp. 2229–36.

S.F. Hassan and M. Gupta: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 2253–58.

Z. Szaraz, Z. Trojanova, M. Cabbibo, and E. Evangelista: Mater. Sci. Eng. A, 2007, vol. 462, pp. 225–29.

L.H. Dai, Z. Ling, and Y.L. Bai: Compos. Sci. Technol., 2001, vol. 61, pp. 1057–63.

D. Hull and D.J. Bacon: Introduction to Dislocations, 4th ed., Butterworth-Heinemann, Oxford, 2002.

S.F. Hassan and M. Gupta: J. Alloys Compd., 2006, vol. 419, pp. 84–90.

S.F. Hassan and M. Gupta: J. Alloys Compd., 2007, vol. 429, pp. 176–83.

C.S. Goh, J. Wei, L.C. Lee, and M. Gupta: Acta Mater., 2007, vol. 55, pp. 5115–21.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta: Composites A, 2011, vol. 42, pp. 180–88.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta: Composites A, 2011, vol. 42, pp. 2093–100.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta: J. Nanomater., 2011. doi:10.1155/2011/642980.

C.J. Smithells and E.A. Brandes: Metals Reference Book, 5th ed., Butterworth & Co Ltd., London, 1976

H. Idrissi, L. Ryelandt, M. Veron, D. Schryvers, and P.J. Jacques: Scripta Mater., 2009, vol. 60, pp. 941–44.

X.Z. Liao, S.G. Srinivasan, Y.H. Zhao, M.I. Baskes, Y.T. Zhu, F. Zhou, E.J. Lavernia, and H.F. Xu: Appl. Phys. Lett., 2004, vol. 84(18), pp. 3564–66.

B. Hammer, K.W. Jacobsen, V. Milman, and M.C. Payne: J. Phys. Condens. Matter, 1992, vol. 4, pp. 10453–60.

N.M. Rosengaard and H.L. Skriver: Phys. Rev. B, 1993, vol. 47(19), pp. 12865–73.

K. Hernadi, A. Fonseca, J.B. Nagy, D. Bernaerts, A. Fudala, and A.A. Lucas: Zeolites, 1996, vol. 17, pp. 416–26.

F. Xu, H. Zhao, and S.D. Tse: Proc. Combust. Inst., 2007, vol. 31, pp. 1839–47.

Q. Zhao, T. Jiang, C. Li, and H. Yin: J. Ind. Eng. Chem., 2011, vol. 17, pp. 218–22.

Acknowledgments

The authors wish to thank the National University of Singapore (NUS) and Temasek Defence Systems Institute (TDSI) for funding this research (TDSI/09-011/1A and WBS# R265000349).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 23, 2012.

Rights and permissions

About this article

Cite this article

Paramsothy, M., Chan, J., Kwok, R. et al. Nitride Nanoparticle Addition to Beneficially Reinforce Hybrid Magnesium Alloys. Metall Mater Trans A 44, 1123–1138 (2013). https://doi.org/10.1007/s11661-012-1433-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1433-9