Abstract

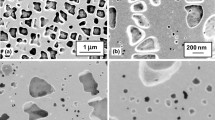

Microstructure evolution during the supersolvus heat treatment of a powder-metallurgy, low-solvus, high-refractory (LSHR) superalloy was established. For this purpose, three lots of LSHR with varying initial carbon/boron composition and thermomechanical history were subjected to a series of short-time (induction) and long-time (furnace) heat treatments followed by scanning electron microscopy/electron backscatter diffraction and quantitative metallography. The size of the (pinned) gamma grains exhibited a limited dependence on heating rate and soak time at peak temperature, and it was generally smaller than the predictions based on the classic Smith-Zener model. The differences were rationalized in terms of stereological and pinning-particle location effects. Observations of limited coarsening of the carbide/boride pinning particles were interpreted in the context of prior experimental observations and a modified Lifshitz-Slyosov-Wagner model applied previously for the coarsening of compound phases in steels.

Similar content being viewed by others

Notes

The shape factor σ for a lognormal distribution is related to the ratio of the standard deviation sx and the mean \( < s > \) of the distribution by the relation \( {\text{s}_{x}}/ < s > = \sqrt {\mathop e\nolimits^{{\sigma^{2} }} - 1} \).

References

R.M. Forbes Jones and L.A. Jackman: JOM, 1999, vol. 51, no. 1, pp. 27–31.

M.J. Donachie Jr., Ed., Superalloys Source Book, ASM International, Materials Park, OH, 1984.

T.P. Gabb, J. Gayda, and J. Falsey: Report NASA/TM-2005-213649, National Aeronautics and Space Administration, Glenn Research Center, Cleveland, OH, 2005, http://gltrs.grc.nasa.gov.

D.D. Krueger, R.D. Kissinger, R.G. Menzies, and C.S. Wukusick: US Patent 4,957,567, 1990.

E.L. Raymond, R.D. Kissinger, A.J. Paxson, and E.S. Huron: US Patent 5,584,947, 1996.

E.S. Huron, J.A. Heaney, D.P. Mourer, J.R. Groh, E.L. Raymond, D.A. Utah, M.J. Weimer, and K.R. Bain: US Patent Application 2009/0000706 A1, 2009.

C. Zener: Private Communication to C.S. Smith in Trans. AIME, 1948, vol. 175, pp. 15–51.

J.W. Martin, R.D. Doherty, and B. Cantor: Stability of Microstructure in Metallic Systems, Cambridge University Press, Cambridge, UK, 1997.

P.A. Manohar, M. Ferry, and T. Chandra: ISIJ Int., 1998, vol. 38, pp. 913–24.

K. Song and M. Aindow: Mater. Sci. Eng. A, 2008, vol. A479, pp. 365–72.

E.J. Payton: Ph.D. Dissertation, The Ohio State University, Columbus, OH, 2009.

C.R. Roberts: Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, 2007.

C.R. Roberts, S.L. Semiatin, and A.D. Rollett: Scripta Mater., 2007, vol. 56, pp. 899–902.

S. Bjorklund, L.F. Donaghey, and M. Hillert: Acta Metall., 1972, vol. 20, pp. 867–74.

S.K. Bhattacharyya and K.C. Russell: Metall. Trans., 1972, vol. 3, pp. 2195–99.

J.E. Morral and G.R. Purdy: Scripta Metall. Mater., 1994, vol. 30, pp. 905–08.

H.M. Lee, S.M. Allen, and M. Grujicic: Metall. Trans. A, 1991, vol. 22A, pp. 2863–68.

H.M. Lee and S.M. Allen: Metall. Trans. A, 1991, vol. 22A, pp. 2877–88.

P. Tao, C. Zhang, Z-G. Yang, and T. Hiroyuki: J. Iron Steel Res., Int., 2010, vol. 17, no. 5, pp, 74–78.

K. Miyata, T. Omura, T. Kushida, and Y. Komizo: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1565–73.

A. Gustafson: Mater. Sci. Eng. A, 2000, vol. A287, pp. 52–58.

D. Ramakrishna and S.P. Gupta: Mater. Sci. Eng., 1987, vol. 92, pp. 179–91.

S. Ghosh: Scripta Mater., 2010, vol. 63, pp. 273–76.

J. Gayda, T.P. Gabb, and P.T. Kantzos: Superalloys 2004, K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, and S. Walston, eds., TMS, Warrendale, PA, 2004, pp. 323–30.

J. Lemsky: Report NASA/CR-2005-213574, Ladish Company, Inc., Cudahy, WI, 2005. http://gltrs.grc.nasa.gov.

S.L. Semiatin and D.R. Barker: US Patent 5,447,580, 1995.

J. Gayda, T.P. Gabb, and P.T. Kantzos: US Patent 6,660,110, 2003.

G.F. Mathey: US Patent 5,312,497, 1994.

S. Ganesh and R.G. Tolbert: US Patent 5,527,020, 1996.

J. Lemsky: Ladish Co., Cudahy, WI, Unpublished research, 2006.

M. Hillert: Acta Metall., 1965, vol. 13, pp. 227–38.

D.J. Srolovitz, M.P. Anderson, and G.S. Grest: Acta Metall., 1984, vol. 32, pp. 793–802.

D.J. Srolovitz, M.P. Anderson, G.S. Grest, and P.S. Sahni: Acta Metall., 1984, vol. 32, pp. 1429–38.

E.S. Huron, R.L. Casey, M.F. Henry, and D.P. Mourer: Superalloys 1996, R.D. Kissinger, D.J. Deye, D.L. Anton, A.D. Cetel, M.V. Nathal, T.M. Pollock, and D.A. Woodford, eds., TMS, Warrendale, PA, 1996, pp. 667–76.

E.S. Huron, K.R. Bain, D.P. Mourer, J.J. Schirra, P.L. Reynolds, and E.E. Montero: Superalloys 2004, K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, and S. Walston, eds., TMS, Warrendale, PA, 2004, pp. 73–81.

E.J. Payton: Institut für Werkstoffe, Ruhr-Universität Bochum, Bochum, Germany, Unpublished research, 2011.

J.C. Russ and R.T. DeHoff: Practical Stereology, Kluwer Academic/Plenum Publishers, New York, NY, 2000.

T.P. Gabb and D.R. Miller: National Aeronautics and Space Administration, Glenn Research Center, Cleveland, OH, Unpublished research, 2010.

T.P. Gabb, J. Gayda, J. Telesman, and P.T. Kantzos: Report NASA/TM-2005-213645, National Aeronautics and Space Administration, Glenn Research Center, Cleveland, OH, 2005, http://gltrs.grc.nasa.gov.

H-J. Jou: Report NASA/CR-2010-216748, QuesTek Innovations LLC, Evanston, IL, July 2010, http://gltrs.grc.nasa.gov.

A.K. Koul and F.B. Pickering: Acta Metall., 1982, vol. 30, pp. 1303–08.

P.R. Rios: Acta Metall., 1987, vol. 35, pp. 2805–14.

H.A. Calderon, P.W. Voorhees, J.L. Murray, and G. Kostorz: Acta Metall. Mater., 1994, vol. 42, pp. 991–1000.

D.S. Berry: J. Appl. Phys., 1973, vol. 44, pp. 3792–93.

M.S.A. Karunaratne, D.C. Cox, P. Carter, and R.C. Reed: Superalloys 2000, T.M. Pollock, R.D. Kisssinger, R.R. Bowman, K.A. Green, M. Mclean, S. Olson, and J.J. Schirra, eds., TMS, Warrendale, PA, 2000, pp. 263–72.

R.V. Patil and G.B. Kale: J. Nucl. Mater., 1996, vol. 230, pp. 57–60.

G. Miyamoto, J.C. Oh, K. Hono, T. Furuhara, and T. Maki: Acta Mater., 2007, vol. 55, pp. 5027–38.

Acknowledgments

This work was conducted as part of the in-house research of the Metals Branch of the Air Force Research Laboratory’s Materials and Manufacturing Directorate. The support and encouragement of the Laboratory management are gratefully acknowledged. The assistance of P.N. Fagin and T.M. Brown in conducting the experiments is appreciated. Technical discussions with J. Gayda and J. Telesman (NASA GRC) are also much appreciated. Two authors (A.D.R. and C.G.R.) also acknowledge support from the Air Force STW-21 Initiative, Contract F33615-01-2-5225, and the MRSEC at Carnegie Mellon University, NSF Grant Number DMR-0520425.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 5, 2011.

Rights and permissions

About this article

Cite this article

Semiatin, S.L., McClary, K.E., Rollett, A.D. et al. Microstructure Evolution during Supersolvus Heat Treatment of a Powder Metallurgy Nickel-Base Superalloy. Metall Mater Trans A 43, 1649–1661 (2012). https://doi.org/10.1007/s11661-011-1035-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-1035-y