Abstract

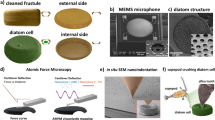

A universal design paradigm in biology is the use of hierarchies, which is evident in the structure of proteins, cells, tissues, and organisms, as well as outside the material realm in the design of signaling networks in complex organs such as the brain. A fascinating example of a biological structure is that of diatoms, a microscopic mineralized algae that is mainly composed of amorphous silica, which features a hierarchical structure that ranges from the nano- to the macroscale. Here, we use the porous structure found at submicron length scales in diatom algae as a basis to study a bioinspired nanoporous material implemented in crystalline silica. We consider the mechanical performance of two nanoscale levels of hierarchy, studying an array of thin-walled foil silica structures and a hierarchical arrangement of foil elements into a porous silica mesh structure. By comparing their elastic, plastic, and failure mechanisms under tensile deformation, we elucidate the impact of hierarchies and the wall width of constituting silica foils on the mechanical properties, by carrying out a series of large-scale molecular dynamics (MD) simulations with the first principles based reactive force field ReaxFF. We find that by controlling the wall width and by increasing the level of hierarchy of the nanostructure from a foil to a mesh, it is possible to significantly enhance the mechanical response of the material, creating a highly deformable, strong, and extremely tough material that can be stretched in excess of 100 pct strain, in stark contrast to the characteristic brittle performance of bulk silica. We find that concurrent mechanisms of shearing and crack arrest lead to an enhanced toughness and are enabled through the hierarchical assembly of foil elements into a mesh structure, which could not be achieved in foil structures alone. Our results demonstrate that including higher levels of hierarchy are beneficial in improving the mechanical properties and deformability of intrinsically brittle materials. The findings reported here provide insight into general material design approaches that may enable us to transform a brittle material such as silicon or silica into a ductile, yet strong and tough material, solely through alterations of its structural arrangement at the nanoscale.

Similar content being viewed by others

References

J. Aizenberg, J.C. Weaver, M.S. Thanawala, V.C. Sundar, D.E. Morse, and P. Fratzl: Science, 2005, vol. 309 (5732), pp. 275–78.

P. Fratzl and R. Weinkamer: Prog. Mater. Sci., 2007, vol. 52, pp. 1263–1334.

R.O. Ritchie, M.J. Buehler, and P. Hansma: Phys. Today, 2009, vol. 62 (6), pp. 41–47.

M.J. Buehler and Y.C. Yung: Nat. Mater., 2009, vol. 8 (3), pp. 175–88.

F.E. Round, R.M. Crawford, and D.G. Mann: Diatoms: Biology and Morphology of the Genera, Cambridge University Press, Cambridge, United Kingdom, 1990.

M. Hildebrand: Chem. Rev., 2008, vol. 108 (11), pp. 4855–74.

J.A. Raven and A.M. Waite: Tansley Rev., 2003, vol. 162, pp. 45–61.

C.E. Hamm and V. Smetacek: in Evolution of Primary Producers in the Sea, P.G. Falkowski and A.H. Knoll, eds., Elsevier, Boston, MA, 2007, pp. 311–32.

S.W. Fowler and N.S. Fisher: Deep Sea Res., 1983, vol. 39 (9), pp. 963–69.

H.-C. Shin, J.A. Corno, J.L. Gole, and M. Liu: J. Power Sources, 2005, vol. 139 (1–2), pp. 314–20.

E.K. Prince, T.L. Myers, and J. Kubanek: Limnol. Oceanogr., 2008, vol. 53 (2), pp. 531–41.

Z. Bao, M.R. Weatherspoon, S. Shian, Y. Cai, P.D. Graham, S.M. Allan, G. Ahmad, M.B. Dickerson, B.C. Church, Z. Kang, H.W. Abernathy Iii, C.J. Summers, M. Liu, and K.H. Sandhage: Nature, 2007, vol. 446 (7132), pp. 172–75.

D. Losic, J.G. Mitchell, and N.H. Voelcker: Adv. Mater., 2009, vol. 21 (29), pp. 2947–58.

N. Tokranova, I.A. Levitsky, B. Xu, J. Castracane, and W.B. Euler: Hybrid Solar Cells Based on Organic Material Embedded into Porous Silicon, SPIE, San Jose, CA, 2005.

C. Jeffryes, T. Gutu, J. Jiao, and G.L. Rorrer: ACS Nano, 2008, vol. 2 (10), pp. 2103–12.

W. Fenical: Plants: the Potentials for Extracting Protein, Medicines, and Other Useful Chemicals: Workshop Proc., Washington, DC, U.S. Government Printing Office, Washington, DC, 1983, pp. 147–53.

J.T. Allen, L. Brown, R. Sanders, C. Mark Moore, A. Mustard, S. Fielding, M. Lucas, M. Rixen, G. Savidge, S. Henson, and D. Mayor: Nature, 2005, vol. 437 (7059), pp. 728–32.

E. Litchman, C.A. Klausmeier, and K. Yoshiyama: Proc. Nat. Acad. Sci., 2009, vol. 106 (8), pp. 2665–70.

C.E. Hamm, R. Merkel, O. Springer, P. Jurkojc, C. Maier, K. Prechtel, and V. Smetacek: Nature, 2003, vol. 421 (6925), pp. 841–43.

D. Losic, K. Short, J.G. Mitchell, R. Lal, and N.H. Voelcker: Langmuir, 2007, vol. 23 (9), pp. 5014–21.

D. Losic, R.J. Pillar, T. Dilger, J.G. Mitchell, and N.H. Voelcker: J. Porous Mater., 2007, vol. 14, pp. 61–69.

A.P. Garcia and M.J. Buehler: Comput. Mater. Sci., 2010, vol. 48 (2), pp. 303–09.

H.S. Park: Nanotechnology, 2009, vol. 20 (11), p. 115701.

T.Y. Kim, S.S. Han, and H.M. Lee: Mater. Trans., 2004, vol. 45 (5), pp. 1442–49.

T.J. Chuang, P.M. Anderson, M.K. Wu, S. Hsieh, and T.-j. Chuang: in Nanomechanics of Materials and Structures, Springer, Netherlands, 2006, pp. 67–78.

T. Namazu and Y. Isono: Sens. Actuat. A, Phys., 2003, vol. 104 (1), pp. 78–85.

H. Ni, X. Li, and H. Gao: Appl. Phys. Lett., 2006, vol. 88 (4), p. 043108.

E.C. Silva, L. Tong, S. Yip, and K.J. Van Vliet: Size Effects on the Stiffness of Silica Nanowires, Small, 2006, vol. 2 (2), pp. 239–43.

J.P Lucas, N.R. Moody, S.L. Robinson, J. Hanrock, and R.Q. Hwang: Scripta Metall. Mater., 1995, vol. 32 (5), pp. 743–48.

D. Bonamy, S. Prades, C. Rountree, L. Ponson, D. Dalmas, E. Bouchaud, K. Ravi-Chandar, and C. Guillot: Int. J. Fract., 2006, vol. 140 (1), pp. 3–14.

M.J. Buehler, H. Tang, A.C.T. van Duin, and W.A. Goddard: Phys. Rev. Lett., 2007, vol. 99, p. 165502.

M.J. Buehler, A.C.T. van Duin, and W.A. Goddard: Phys. Rev. Lett., 2006, vol. 96 (9), p. 095505.

J.C. Fogarty, H.M. Aktulga, A.Y. Grama, A.C.T. van Duin, and S.A. Pandit: J. Chem. Phys., 2010, vol. 132 (17), pp. 174704–10.

A.C.T. van Duin, S. Dasgupta, F. Lorant, and W.A. Goddard: J. Phys. Chem. A, 2001, vol. 105, p. 9396.

A.C.T. van Duin, A. Strachan, S. Stewman, Q. Zhang, X. Xu, and W.A. Goddard: J. Phys. Chem. A, 2003, vol. 107 (19), pp. 3803–11.

W.W. Zhang, Q.A. Huang, H. Yu, and L.B. Lu: in Micro and Nano Technology—1st Int. Conf. of Chinese Society of Micro/Nano Technology (Csmnt), X. Wang, ed., Trans Tech Publications Ltd., Stafa-Zurich, 2009, pp. 315–19.

D. Raymand, A.C.T. van Duin, M. Baudin, and K. Hermansson: Surf. Sci., 2008, vol. 602 (5), pp. 1020–31.

W. Liu, K. Zhang, H. Xiao, L. Meng, J. Li, G.M. Stocks, and J. Zhong: Nanotechnology, 2007, vol. 18 (21), p. 215703.

H.J.C. Berendsen, J.P.M. Postma, W.F. van Gunsteren, A. DiNola, and J.R. Haak: J. Chem. Phys., 1984, vol. 81 (8), pp. 3684–90.

J.A. Zimmerman, E.B. Webb III, J.J. Hoyt, R.E. Jones, P.A. Klein, and D.J. Bammann: Model. Sim. Mater. Sci. Eng., 2004, vol. 12, pp. S319–S332.

T. Zhu, J. Li, S. Yip, R.J. Bartlett, S.B. Trickey, and N.H. de Leeuw: Molec. Simul., 2003, vol. 29 (10), pp. 671–76.

E. Silva, J. Li, D. Liao, S. Subramanian, T. Zhu, and S. Yip: J. Comput. Aided Mater. Des., 2006, vol. 13 (1), pp. 135–59.

H. Kimizuka, S. Ogata, and Y. Shibutani: Phys. Status Solidi (b), 2007, vol. 244 (3), pp. 900–09.

B. Wu, A. Heidelberg, J.J. Boland, J.E. Sader, X.M. Sun, and Y.D. Li: Nano Lett., 2006, vol. 6 (3), pp. 468–72.

H. Liang, M. Upmanyu, and H. Huang: Phys. Rev. B, 2005, vol. 71 (24), p. 241403.

C.L. Rountree, S. Prades, D. Bonamy, E. Bouchaud, R. Kalia, and C. Guillot: J. Alloys Compd., 2007, vols. 434–435, pp. 60–63.

H. Mehrez and S. Ciraci: Phys. Rev. B, 1997, vol. 56 (19), p. 12632.

S. Keten, Z. Xu, B. Ihle, and M.J. Buehler: Nat. Mater., 2010, vol. 9, pp. 359–67.

N. Kroger: Curr. Opin. Chem. Biol., 2007, vol. 11 (6), pp. 662–69.

N. Lundholm, Ø. Moestrup, G.R. Hasle, and K. Hoef-Emden: J. Phycol., 2003, vol. 39 (4), pp. 797–813.

Acknowledgments

We acknowledge support from the Army Research Office (Grant No. W9-11NNF-06-1029), the National Science Foundation through a Graduate Research Fellowship, the Gates Millennium Scholars Program, and a graduate research fellowship awarded by the Department of Civil and Environmental Engineering at the Massachusetts Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 19, 2010.

Rights and permissions

About this article

Cite this article

Garcia, A.P., Sen, D. & Buehler, M.J. Hierarchical Silica Nanostructures Inspired by Diatom Algae Yield Superior Deformability, Toughness, and Strength. Metall Mater Trans A 42, 3889–3897 (2011). https://doi.org/10.1007/s11661-010-0477-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0477-y