Abstract

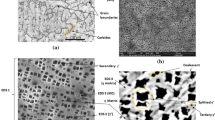

For the repair of single-crystalline turbine components, fabricated from nickel-based superalloys, a new high-temperature brazing technology has been developed. Cracks in single-crystalline parts can be repaired by reproducing the single-crystalline microstructure over the complete gap width within very short brazing times. Nickel-manganese–based alloys were identified as systems that provide very high, epitaxial solidification rates. In contrast to commonly used braze alloys, such as nickel-boron or nickel-silicon systems, the process is not completely diffusion controlled but works with consolute systems. For brazing experiments 300-μm-wide parallel gaps as well as V-shaped gaps with a maximum width of 250 μm were used. A complete epitaxial solidification, that is, the absence of large-angle grain boundaries, could be achieved within brazing times, being up to 100 times shorter compared to commonly used transient-liquid-phase bonding technologies. To quantify the misorientation relative to the base material and the composition within and near the filled gaps, the results of the brazing experiments were visualized by means of light microscopy and scanning electron microscopy (SEM). Furthermore, electron backscatter diffraction (EBSD) analyses and energy dispersive X-ray (EDX) analyses were conducted.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Notes

The term azeotropic composition is used according to the definition as constant boiling mixture. In this case, the liquidus and solidus line contact each other; the composition of the liquid and the solid phase are the same.

DSC404C PEGASUS is a trademark of Netzsch-Gerätebau GmbH, Selb, Germany.

References

K.C. Antony and G.W. Goward: Proceedings of the 6th Int. Symposium on Superalloys, Champion, PA, 1988, pp. 745–54

O.A. Idowu, N.L. Richards, and M.C. Chaturvedi: Mater. Sci. Eng., A, 2005, vol. 397, pp. 98–112

W. Li, T. Jin, X. Sun, Y. Guo, and H. Guan: J. Mater. Sci. Technol., 2002, vol. 18, pp. 54–56

P. Brauny, M. Hammerschmidt, and M. Malik: Mater. Sci. Technol., 1984, vol. 1, pp. 719–27

S. Humm: Untersuchungen zur Entwicklung eines Reparaturverfahrens für einkristalline und gerichtet erstarrte Turbinenkomponenten aus Nickelbasissuperlegierungen, RWTH, Aachen, 2003, pp. 7–25

O.A. Idowu, O.A. Ojo, and M.C. Chaturvedi: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2787–96

B. Hoppe: Ph.D. Thesis, TU Braunschweig, 2003, pp. 15–36

D.S. Duvall, W.A. Owczarski, and D.F. Paulonis: Weld. J., 1974, vol. 53 (4), pp. 203–214

B. Heine: Metall, 1995, vol. 6, pp. 393–400

K.A. Ellison, P. Lowden, and J. Liburdi: J. Eng. Gas Turb. Power, 1994, vol. 116, pp. 237–42

L.S.K. Heikinheimo, A. Laukkanen, and J. Veivo: Weld. World, 2005, vol. 49 (5–6), pp. 5–12

A. Schnell: Ph.D. Thesis, EPF de Lausanne, 2004, pp. 93–98

J.-P. Jung, B.-Y. Lee, and C.-S. Kang: International Trends in Welding Science and Technology: Proc. Int. Conf., 1993, pp. 1101–05

D.U. Kim: J. Kor. Inst. Met. Mater., 2001, vol. 39 (5), pp. 589–94

K. Nishimoto, K. Saida, D. Kim, and Y. Nakao: Weld. World, 1998, vol. 41 (2), pp. 121–31

J.E. Ramirez, and S. Liu: Weld. J., 1992, vol. 71 (10), pp. 365–75

T.B. Massalski: Binary Alloy Phase Diagrams, ASM, Metals Park, OH, 1988, vol. 2, p. 1573

B. Laux, S. Piegert, and J. Rösler: J. Eng. Gas Turbines Power, 2008, in press

E. Schatt and H. Worch: Werkstoffwissenschaft. Deutscher Verlag für Grundstoffindustrie, Stuttgart, 1996, pp. 88–89

R. Bürgel: Handbuch Hochtemperatur-Werkstofftechnik, Vieweg & Sohn Verlagsges, mbH, Braunschweig, Wiesbaden, 2001, pp. 407–24

P.R. Sahm, I. Egry, and T. Volkmann: Schmelze, Erstarrung, Grenzflächen, Vieweg & Sohn Verlagsgesellschaft mbH, Braunschweig, Wiesbaden, 1999, pp. 138–51

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 16, 2007.

Rights and permissions

About this article

Cite this article

Laux, B., Piegert, S. & Rösler, J. Braze Alloy Development for Fast Epitaxial High-Temperature Brazing of Single-Crystalline Nickel-Based Superalloys. Metall Mater Trans A 40, 138–149 (2009). https://doi.org/10.1007/s11661-008-9702-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9702-3