Abstract

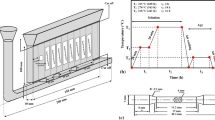

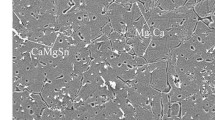

The grain-refinement effects of titanium (Ti) additions and a low-frequency electromagnetic casting (LFEC) process on the AZ31 magnesium alloy have been investigated. It is shown that Ti has no effect on the formation and distribution of secondary phases in the AZ31 alloy. The results suggests that the grain size decreases with an increasing cooling rate for the AZ31 alloy; it decreases first, however, then increases slightly for Ti-containing AZ31 alloys, indicating that the grain-refinement effect of Ti decreases with an increasing cooling rate. However, the grain size decreases first, and then increases with increasing Ti for a given cooling rate. The lowest grain size is obtained at the addition of about 0.01% Ti and the cooling rate of about 6 K/s. The grain refinement effect is explained in terms of the growth restriction factor (GRF) due to the constitutional undercooling generated by the Ti solute elements, which produces grain refinement up to a critical GRF value corresponding to about 0.01% Ti addition. The yield strength of a conventional-cast AZ31 alloy can be improved by grain refinement and expressed as σ y = 39.31 + 142.53 d −1/2 according to the Hall−Petch relationship. The combination of the Ti grain refiner and the LFEC process during direct-chill (DC) casting of an AZ31 alloy can produce high-quality magnesium alloy billets with uniform and equiaxed grains of less than 40 μm across the billet section up to at least a 100-mm diameter, which further improves the yield strength of the alloy, resulting in σ y = 51.53 + 90.85 d −1/2.

Similar content being viewed by others

References

T.C. Chang, J.Y. Wang, O. Lee: J. Mater. Process. Technol., 2003, vol. 140, pp. 588–91

A.A Luo: SAE Technical Paper 2005-01-0734, Society for Automotive Engineers International, Warrendale, PA, 2005, pp. 411–21

V. Kaese, L. Greve, S. Jutter, M. Goede, S. Schumann, H. Friedrich, W. Holl, and W. Ritter: Proc. 6th Int. Conf. Magnesium Alloys and Their Applications, K.U. Kainer, ed., Wiley-VCH, Weinheim, Germany, 2003, pp. 949–54

Y.X. Wang, X.Q. Zeng, W.J. Ding: Scripta Mater., 2006, vol. 54, pp. 269–73

D.H. St John, M. Qian, M.A. Easton, P. Cao, Z. Hildebrand: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1669–79

Y.X. Wang, X.Q. Zeng, W.J. Ding, A.A. Luo, A.K. Sachdev: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1333–41

J. Dong, J.Z. Cui, F.X. Yu, C.Y. Ban, Z.H. Zhao: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2487–94

S.J. Guo, Q.C. Le, Z.H. Zhao, Z.J. Wang, J.Z. Cui: Mater. Sci. Eng., 2005, vol. 404A, pp. 323–29

J.Z. Cui, Q.C. Le, S.J. Guo, X.J. Zhang, Z.H. Zhao: China Materials Forum 2002, CMS, Beijing, China, 2002, pp. 26–33

M. Easton, D.H. St John: Metall. Mater. Mater. Trans. A, 1999, vol. 30A, pp. 1625–33

F. Xue, W.W. Du, Y.S. Sun: Mater. Sci. Forum, 2005, vols. 488–489, pp. 143–46

Y.X. Wang: Doctoral Paper, Shanghai Jiao Tong University, Shanghai, P.R. China, 2006

M. Johnsson, L. Bäckerud: Z. Metallkd., 1996, vol. 87, pp. 216–20

Y.C. Lee, A.K. Dahle, D.H. St John: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2895–906

J.L. Murray: Bull. Alloy Phase Diagrams, 1986, vol. 7, pp. 245–48

J. Lipton, M.E. Glicksman, W. Kurz: Mater. Sci. Eng., 1984, vol. 65A, pp. 57–63

M. Johnsson: Thermochimica Acta, 1995, vol. 256, pp. 101–21

M. Easton, D.H. St John: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1613–24

Acknowledgment

This work was performed as a collaborative research program “Development of low cost magnesium alloy extrusions” supported by Shanghai Jiao Tong University (Shanghai, China) and General Motors Corporation (Warren, MI).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 27, 2006.

Rights and permissions

About this article

Cite this article

Wang, Y., Zeng, X., Ding, W. et al. Grain Refinement of AZ31 Magnesium Alloy by Titanium and Low-Frequency Electromagnetic Casting. Metall Mater Trans A 38, 1358–1366 (2007). https://doi.org/10.1007/s11661-007-9215-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9215-5