Abstract

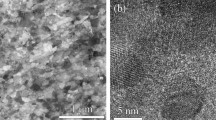

The present article reports on the formulation of an analytical model to predict the size scale of oxide dispersoids in Al alloys processed by a reactive atomization and consolidation synthesis approach. The proposed model formulation is primarily based on the assumption that all of the strain energy in the oxides is used to create interfaces between the oxide dispersoids and the matrix. The following predictions are made, based on the preceding analytical model. First, the diameter or thickness of oxide discs (the oxide dispersoids are assumed to have a disc geometry) constantly decreases with increasing strain. However, when exposed to the range of strain levels that are present in conventional processes (e.g., less than 100:1, 90 pct, and 90 pct of area, thickness, and height reduction ratio in extrusion, rolling, and forging, respectively), the oxide discs will fracture into sizes that are on the order of tens of nanometers in both diameter and thickness. Ultra-high strain levels (e.g., more than 18.5 of total strain) are required to obtain ultra-fine oxide discs whose diameter and thickness are on the order of nanometers. Second, working temperature appears to exert only limited influence on the final diameter or thickness of the oxide discs. The size scale of oxide dispersoids predicted on the basis of the analytical model presented herein is in good agreement with the available experimental observations.

Similar content being viewed by others

References

E.J. Lavernia and Y. Wu: Spray Atomization and Deposition, John Wiley & Sons Inc., New York, NY, 1996, pp. 7–9, 278–79, and 398–99.

P.S. Grant: Progr. Mater. Sci., 1995, vol. 39, pp. 497–545.

S.L. Dai, J.-P. Delplanque, and E.J. Lavernia: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2597–2611.

H. Liu, R.H. Rangel, and E.J. Lavernia: Acta Metall. Mater., 1994, vol. 42, pp. 3277–89.

X. Zeng, H. Liu, M. Chu, and E.J. Lavernia: Metall. Trans. A, 1992, vol. 23A, pp. 3394–99.

X. Zeng, S. Nutt, and E.J. Lavernia: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 817–27.

F.J. Humphreys and J.W. Martin: Phil. Mag., 1968, vol. 17, pp. 365–80.

O. Preston and N.J. Grant: Trans. TMS-AIME, 1961, vol. 221, pp. 164–73.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Pergamon, Oxford, United Kingdom, 1995, pp. 78, 146, 256, and 306.

Y.J. Lin, Y. Zhou, and E.J. Lavernia: J. Mater. Res., 2004, vol. 19, pp. 3090–98.

Y.W. Kim, W.M. Griffith, and F.H. Froes: J. Met., 1985, vol. 37, pp. 27–33.

Y.J. Lin, Y. Zhou, and E.J. Lavernia: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 1173–85.

Y.J. Lin, Y. Zhou, and E.J. Lavernia: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3265–73.

G.W. Rowe: Elements of Metalworking Theory, Edward Arnold Ltd., London, 1979, pp. 23 and 37.

J.N. Harris: Mechanical Working of Metals, Pergamon Press Ltd., Oxford, United Kingdom, 1983, pp. 53, 86–87, and 98.

N.R. Bauld: Mechanics of Materials, Prindle, Weber & Schmidt Publisher, Boston, MA, 1986, pp. 54 and 567.

G.A. Roberts and R.A. Cary: Tool Steels, ASM, Materials Park, OH, 1980, pp. 633–40.

G.V. Samsonov: Oxide Handbook, C.N. Turton, and T.I. Turton, translators, IFI/Plenum Data Corporation, New York, NY, 1973, pp. 105–14 and 235–42.

D.A. Porter and K.E. Easterling: Phase Transformations in Metals and Alloys, Stanley Thorns (Publishers) Ltd., London, United Kingdom, 1992, p. 315.

J.R. Groza: in Nanostructured Materials, C.C. Koch, ed., Noyes Publications, Norwich, NY, 2002, pp. 125 and 155–57.

T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak: Binary Alloy Phase Diagrams, ASM INTERNATIONAL, Materials Park, OH, 1990, pp. 1–3542.

Y.V.R.K. Prasad and S. Sasidhara: Hot Working Guide, ASM INTERNATIONAL, Materials Park, OH, 1997, pp. 25–448.

M.I. Alymov, E.I. Maltina, and Y.N. Stepanov: Nanostr. Mater., 1994, vol. 4, pp. 737–42.

S.L. Dai, J.-P. Delplanque, and E.J. Lavernia: J. Mater. Res., 1999, vol. 14, pp. 2814–23.

J.R. Davis: Aluminum and Aluminum Alloys, ASM INTERNATIONAL, Materials Park, OH, 1993, p. 494.

J.A.S. Tenorio and D.C.R. Espinosa: Oxid. Met., 2000, vol. 53, pp. 361–73.

T.J. Carney, P. Tsakiropoulos, J.F. Watts, and J.E. Watts, and J.E. Castle: Int. J Rapid Solidification, 1990, vol. 5, pp. 189–217.

E.A. Brandes and G.B. Brook: Smithells Metals Reference Book, Butterworths-Heinemann, Oxford, United Kingdom, 1992, pp. 8–1, 8–2, 8–25, and 14–7.

R. Asthana: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 225–30.

G.V. Samsonov: Oxide Handbook, translated from Russian by C.N. Turton and T.I. Turton, IFI/Plenum Data Corporation, New York, NY, 1982, pp. 51, 173, 183, and 187–88.

J.R. Newby: Metals Handbook, 9th ed., ASM, Metals Park, OH, 1985, vol. 8, p. 23.

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai: Acta Mater., 1999, vol. 47, pp. 579–83.

V.M. Segal: Mater. Sci. Eng. A, 1995, vol. 197, pp. 157–64.

J. Lee, F. Zhou, K.H. Chung, N.J. Kim, and E.J. Lavernia: Metall. Mater. Trans. A, 2001, vol. 32, pp. 3109–15.

M.J. Luton, C.S. Jayanth, M.M. Disco, S. Matras, and J. Vallone: in Multicomponent Ultrafine Microstructures, L.E. McCandlish, B.H. Kear, D.K. Polk, and R.W. Siegel, eds., Materials Research Society, Pittsburgh, PA, 1989, pp. 79–86.

R.J. Perez, H.G. Jiang, C.P. Dogan, and E.J. Lavernia: Metall. Mater. Trans. A, 1998, vol. 29, pp. 2469–75.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, Y., Zhou, Y. & Lavernia, E.J. Modeling of oxide dispersions in reactively processed al. Metall Mater Trans A 36, 177–186 (2005). https://doi.org/10.1007/s11661-005-0150-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0150-z