Abstract

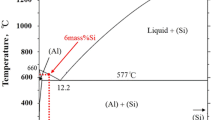

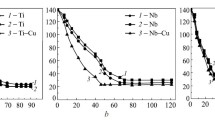

The effect of magnesium and silicon additions to aluminum, free silicon on the SiC substrate, nitrogen gas in the atmosphere, and process temperature on the wetting characteristics of SiC by aluminum alloys are investigated using the sessile drop technique. The contribution of each of these parameters and their interactions to the contact angle, surface tension, and driving force for wetting are determined. In addition, an optimized process for enhanced wetting is suggested and validated. Results show that the presence of free silicon on the surface of SiC significantly reduces the contact angle between the molten alloy and the substrate. The positive effect of silicon on the contact angle is attributed to a chemical reaction in which both SiC and aluminum are active participants. The results also indicate that nitrogen gas in the atmosphere positively influences the liquid/vapor surface tension, and the presence of magnesium in the aluminum alloy favorably affects the overall driving force for wetting. A mechanism is proposed to explain the beneficial role that the interaction of nitrogen with magnesium plays in enhancing wetting. Magnesium significantly reduces the surface tension of aluminum melts but has a low vapor pressure. Consequently, it readily volatilizes during holding at the processing temperature and is lost from the alloy. It is proposed that a series of chemical reactions in the system Al-Mg-N are responsible for reintroducing magnesium into the melt, thus, maintaining a low melt surface tension. Interactions between the aluminum alloy and the silicon carbide substrate that may lead to the dissolution of the substrate and the formation of undesirable reaction products, particularly Al4C3, are examined, and means for mitigating their formation are outlined.

Similar content being viewed by others

References

B. Maruyama: The AMPTIAC Newsletter, 1998, vol. 3, pp. 1–8.

S. Suresh, A. Mortensen, and A. Needleman: Fundamentals of Metal Matrix Composites, 1st ed., Butterworth-Heinemann Co., Stoneham, MA, 1993, pp. 3–22.

J.R. Davis: Aluminum and Aluminum Alloys, ASM Specialty Handbook, 4th ed., ASM INTERNATIONAL, Materials Park, OH, 1998, pp. 160–179.

F. Delannay, L. Froyen, and A. Deruyttere: J. Mater. Sci., 1987, vol. 22, pp. 1–16.

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia: J. Mater. Sci., 1991, vol. 26, pp. 1137–56.

M.K. Aghajanian, M.A. Rocazella, J.T. Burke, and S.D. Keck: J. Mater. Sci., 1991, vol. 26, pp. 447–54.

M.I. Pech-Canul, R.N. Katz, and M.M. Makhlouf: Worcester Polytechnic Institute, Worcester, MA, unpublished research, 1998.

D.R. White, A.W. Urquhart, and M.K. Aghajanian: U.S. Patent No. 5,395, 701, 1995.

A.W. Adamson: Physical Chemistry of Surfaces, 1st ed., Interscience Publishers, New York, NY, 1960, pp. 355–60.

L.E. Murr: Interfacial Phenomena in Metals and Alloys, 1st ed., Addison-Wesley Publishing Co., Reading, MA, 1975, pp. 87–95.

T. Iiada and R.I.L. Guthrie: The Physical Properties of Liquid Metals, 1st ed., Clarendon Press, Oxford, United Kingdom, 1988, pp. 109–19.

V. Laurent, D. Chatain, and N. Eustathopoulos: J. Mater. Sci., 1987, vol. 22, pp. 244–50.

J. Goicoechea, C. Garcia-Cordovilla, E. Louis, and A. Pamies: J. Mater. Sci., 1992, vol. 27, pp. 5247–52.

A. Alonso, C. Garcia-Cordovilla, E. Louis, J. Narciso, and A. Pamies: J. Mater. Sci., 1994, vol. 29, pp. 4729–35.

B.C. Pai, Geetha Kamani, R.M. Pillai, and K.G. Satyanarayana: J. Mater. Sci., 1995, vol. 30 pp. 1903–11.

T. Iseki, T. Kameda, and T. Maruyama: J. Mater. Sci., 1984, vol. 19, pp. 1692–98.

J.C. Viala, P. Fortier, and J. Bouix: J. Mater. Sci., 1990, vol. 25, pp. 1842–50.

A. Alonso, J. Narciso, A. Pamies, C. Garcia-Cordovilla, and E. Louis: Scripta Metall. Mater., 1993, vol. 29, pp. 1559–64.

R.Y. Lin, R.J. Arsenault, G.P. Martins, and S.G. Fishman: Interfaces in Metal-Ceramic Composites, TMS, Warrandale, PA, 1990, pp. 291–302.

R. Roy: A Primer on the Taguchi Method, Van Nostrand Reinhold, New York, NY, 1990, pp. 40–75.

V. Laurent, D. Chatain, and N. Eustathopoulos: J. Mater. Sci. Eng, 1991, vol. A135, pt. 89–94.

R.L. Mehan and D.W. Mckee: J. Mater. Sci., 1976, vol. 11, pp. 1009–18.

John E. Hatch: Aluminum, Properties and Physical Metallurgy, 1st ed., ASM, Metals Park, OH, 1984, pp. 208–9.

S.Y. OH, J.A. Cornie, and K.C. Russell: Metall. Trans. A, 1989, vol. 20A, pp. 533–41.

Q. Hou, R. Mutharasan, and M. Koczak: J. Mater. Sci. Eng. A, 1995, vol. A195, pp. 121–9.

J.C. Viala, F. Bosselet, V. Laurent, and Y. Lepetitcorps: J. Mater. Sci., 1993, vol. 28, pp. 5301–12.

T.Y. Kosolapova: Carbides Properties, Production and Applications, 1st ed., Plenum Press, New York, NY, 1971, pp. 250–4.

M.I. Pech-Canul, R.N. Katz, and M.M. Makhlouf: Worcester Polytechnic Institute, Worcester, MA, unpublished research, 1999.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pech-Canul, M.I., Katz, R.N. & Makhlouf, M.M. Optimum parameters for wetting silicon carbide by aluminum alloys. Metall Mater Trans A 31, 565–573 (2000). https://doi.org/10.1007/s11661-000-0291-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0291-z