Abstract

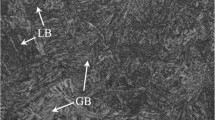

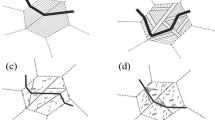

The high strength bridge steel was processed with the simulated coarse grain heat affected zone (CGHAZ) thermal cycle with heat input varying from 30 to 60 kJ/cm, the microstructures were investigated by means of optical microscope (OM), scanning electron microscope (SEM), electron backscattering diffraction (EBSD) and transmission electron microscope (TEM), and the impact properties were evaluated from the welding thermal cycle treated samples. The results indicate that the microstructure is primarily composed of lath bainite. With decreasing heat input, both bainite packet and block are significantly refined, and the toughness has an increasing tendency due to the grain refinement. The fracture surfaces all present cleavage or fracture for the samples with different heat inputs. Moreover, the average cleavage facet size for the CGHAZ is nearly equal to the average bainite packet size and the bainitic packet boundary can strongly impede the crack propagation, indicating that the bainitic packet is the most effective unit in control of impact toughness in the simulated CGHAZ of high strength bridge steel.

Similar content being viewed by others

References

Shin SY, Hwang B, Lee S, et al. Correlation of Microstructure and Charpy Impact Properties in API X70 and X80 Line-pipe Steels[J]. Mater. Sci. Eng. A, 2007, 458: 281–289

Zhao W, Wang W, Chen S, et al. Effect of Simulated Welding Thermal Cycle on Microstructure and Mechanical Properties of High Strength Bridge Steel[J]. Mater. Sci. Eng A, 2011, 528(5): 7417–7422

Davis CL, King JE. Cleavage Initiation in the Intercritically Reheated Coarse-grained Heat-affected Zone: Part I. Fractographic Evidence[J]. Metall. Mater. Trans. A, 1994, 25(7): 563–73

Hu J, Du L-X, Wang J-J, et al. Effect of Welding Heat Input on Microstructures and Toughness in Simulated CGHAZ of V-N High Strength Steel[J]. Mater. Sci. Eng. A, 2013, 577(6): 161–168

Wei R, Wu KM, Gao Z. Effect of Heat Input on Impact Toughness of Coarse-Grained Heat-Affected Zone of a Nb-Ti Microalloyed Bridge Steel[J]. Adv. Mater. Res., 2012,538(5): 2026–2031

Li R, Zuo X, Hu Y, et al. Microstructure and Properties of Bridge Steel with a Ferrite/Martensite Dual-phase Microstructure[J]. Mater. Charact, 2011, 62(5): 801–806

Lambert-Perlade A, Gourgues AF, Pineau A. Austenite to Bainite Phase Transformation in the Heat-affected Zone of a High Strength Low Alloy Steel[J]. Acta Mater., 2004, 52(7): 2337–2348

Guo A, Misra RDK, Liu J, et al. An Analysis of the Microstructure of the Heat-affected Zone of an Ultra-low Carbon and Niobium-bearing Acicular Ferrite Steel Using EBSD and Its Relationship to Mechanical Properties[J]. Mater. Sci. Eng. A, 2010,527(3): 6440–6448

You Y, Shang C, Chen L, et al. Investigation on the Crystallography of the Transformation Products of Reverted Austenite in Intercritically Reheated Coarse Grained heat Affected Zone[J]. Mater. Des., 2013, 43(9): 485–491

Sung HK, Shin SY, Cha W, et al. Effects of Acicular Ferrite on Charpy Impact Properties in Heat Affected Zones of Oxide-containing API X80 Linepipe Steels[J]. Mater. Sci. Eng. A, 2011,528(21): 3350–3357

Morito S, Tanaka H, Konishi R, et al. The Morphology and Crystallography of Lath Martensite in Fe-C Alloys[J]. Acta. Mater., 2003, 51(9): 1789–1799

Morito S, Saito H, Ogawa T, et al. Effect of Austenite Grain Size on the Morphology and Crystallography of Lath Martensite in Low Carbon Steels[J]. ISIJ Int., 2005, (8)45: 91–94

Wang C, Wang M, Shi J, et al. Effect of Microstructural Refinement on the Toughness of Low Carbon Martensitic Steel[J]. Scripta. Mater., 2008, 58: 492–495

Lee S, Kim BC, Lee DY. Fracture Mechanism in Coarse Grained HAZ of HSLA Steel Welds[J]. Scr. Metall., 1989, 23(10): 995–1000

Kim YM, Kim SK, Lim YJ, et al. Effect of Microstructure on the Yield Ratio and Low Temperature Toughness of Linepipe Steels[J]. ISIJ Int., 2002, 42(7): 1571–1577

Rancel L, Gómez M, Medina SF, et al. Measurement of Bainite Packet Size and Its Influence on Cleavage Fracture in a Medium Carbon Bainitic Steel[J]. Mater. Sci. Eng. A,2011,530(9): 21–27

Zhang C, Wang Q, Ren J, et al. Effect of Martensitic Morphology on Mechanical Properties of an As-quenched and Tempered 25CrMo48V Steel[J]. Mater. Sci. Eng. A, 2012,534(6): 339–346

Yang Y, Shang C, Wenjin N, et al. Investigation on the Microstructure and Toughness of Coarse Grained Heat Affected Zone in X-100 Multiphase Bridge Steel with High Nb Content[J]. Mater. Sci. Eng. A, 2012, 558(5): 692–701

Shanmugam S, Ramisetti NK, Misra RDK, et al. Microstructure and High Strength–toughness Combination of a New 700 MPa Nb-microalloyed Bridge Steel[J]. Mater. Sci. Eng. A, 2008,478: 26–37

Zhao M-C, Yang K, Xiao F-R, et al. Continuous Cooling Transformation of Undeformed and Deformed Low Carbon Bridge Steels[J]. Mater. Sci. Eng. A, 2003, 355: 126–136

Wang S-C, Yang J-R. Effects of Chemical Composition, Rolling and Cooling Conditions on the Amount of Martensite/austenite (M/A) Constituent Formation in Low Carbon Bainitic Steels[J]. Mater. Sci. Eng. A, 1992, 154(3): 43–49

Yakubtsov IA, Poruks P, Boyd JD. Microstructure and Mechanical Properties of Bainitic Low Carbon High Strength Plate Steels[J]. Mater. Sci. Eng. A, 2008, 480: 109–116

Furuhara T, Kawata H, Morito S, et al. Crystallography of Upper Bainite in Fe–Ni–C Alloys[J]. Mater. Sci. Eng. A, 2006, 431(7): 228–236

Qiao GY, Han Y and Han XL. Microstructure and Mechanical Properties of Welding Heat Affected Zone of High-Nb High Strength Pipeline Steel[J]. Journal of Iron and Steel Research, 2014, 26(10): 40–45

Olasolo M, Uranga P, Rodriguez-Ibabe JM, et al. Effect of Austenite Microstructure and Cooling Rate on Transformation Characteristics in a Low Carbon Nb-V Microalloyed Steel[J]. Mater. Sci. Eng. A, 2011, 528: 2559–2569

Naylor JP, Krahe PR. Cleavage Planes in Lath Type Bainite and Martensite[J]. Metall Trans. A, 1975,(2)6: 594–598

Lan L, Qiu C, Zhao D, et al. Microstructural Characteristics and Toughness of the Simulated Coarse Grained Heat Affected Zone of High Strength Low Carbon Bainitic Steel[J]. Mater. Sci. Eng. A, 2011, 529(2): 192–200

Yang X Zh, Zhang L, Shi Y Sh, et al. Effect of Niobium Addition on Hot Deformation Behaviors of Medium Carbon Ultra-high Strength Steels[J]. Journal of Wuhan University of Technology-Mater. Sci Ed., 2017, 32(1): 1–28

Daigne J, Guttmann M, Naylor JP. The Influence of Lath Boundaries and Carbide Distribution on the Yield Strength of 0.4% C Tempered Martensitic Steels[J]. Mater. Sci. Eng., 1982, 56: 1–10

Yang L Q, Sui Y l, Xia P P, et al. Microstructure and Toughness of Weld CGHAZ under Different Heat Input for X90 High Strength Pipeline Steel[C]. Proceedings of the 2016 11th International Pipeline Conference., IPC2016

Acknowledgments

Thanks for the supporting tests of State Key Laboratory of Material Processing and Die & Mould Technology and Analysis and Test Center in Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supported by the National 863 Program of China (No.2015AA042505), State Key Laboratory of Materials Processing and Die & Mould Technology of Huazhong University of Science and Technology (No.P2018-014), Major Science and Technology Project in Guangdong Province (No.2014B010130001)

Rights and permissions

About this article

Cite this article

Yang, X., Zhang, L., Shi, Y. et al. Effective microstructure unit in control of impact toughness in CGHAZ for high strength bridge steel. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 177–184 (2018). https://doi.org/10.1007/s11595-018-1803-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1803-2