Abstract

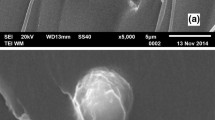

Fly ash cenospheres (FACs) as a recycling material of industrial waste has become a competitor for other inorganic particle fillers. Epoxy resin (EP) composites reinforced with different content of FACs as well as different size grading ratio were prepared. The surface modification of FACs particles was conducted before incorporating into EP matrix. The impact and flexural strengths and the flexural modulus were investigated, and the fracture surfaces of the testing samples were analyzed using SEM. Results showed that FACs had an obvious effect on the mechanical characteristics of the FACs/EP composites. With increasing weight fraction of FACs, the impact and flexural strengths and the flexural modulus of EP composite samples increased, and reached the highest values when the weight fraction of FACs reached 15 wt%. The mechanical characteristics of the FACs/EP composites however deteriorated with further increasing of FACs content. For the EP composites reinforced with different size grading ratio of FACs, the larger proportion of small FACs particles, the better mechanical properties of the EP composites. The results were analyzed from the aspect of the plastic deformation, new surface formation and fracture absorption energy. The synergistic effect of the size grading ratio of FACs was not obvious, which would be further investigated.

Similar content being viewed by others

References

He H W, Li K X, Wang J, et al. Study on Thermal and Mechanical Properties of Nano-calcium Carbonate/epoxy Composites[J]. Mater. Des., 2011, 32: 4521–4527

Sun T, Fan H Y, Wang Z, et al. Modified Nano Fe2O3-epoxy Composite with Enhanced Mechanical Properties[J]. Mater. Des., 2015, 87: 10–16

Sharmila T K B, Antony J V, Jayakrishnan M P, et al. Mechanical, Thermal and Dielectric Properties of Hybrid Composites of Epoxy and Reduced Graphene Oxide/iron Oxide[J]. Mater. Des., 2016, 90: 66–75

Kang Y K, Chen X H, Song S Y, et al. Friction and Wear Behavior of Nanosilica-filled Epoxy Resin Composite Coatings[J]. Appl. Surf. Sci., 2012, 258: 6384–6390

Zhou H L, Liu H Y, Zhou H M, et al. On Adhesive Properties of Nano-silica/epoxy Bonded Single-lap Joints[J]. Mater. Des., 2016, 95: 212–218

Wang F Z, Drzal L T, Qin Y, et al. Enhancement of Fracture Toughness, Mechanical and Thermal Properties of Rubber/epoxy Composites by Incorporation of Graphene Nanoplatelets[J]. Compos. Part A, 2016, 87: 10–22

Sprenger S. Epoxy Resins Modified with Elastomers and Surface-modified Silica Nanoparticles[J]. Polymer, 2013, 54: 4790–4797

Beylergil B, Tanoglu M, Aktas E. Enhancement of Interlaminar Fracture Toughness of Carbon Fiber-epoxy Composites Using Polyamide-6,6 Electrospun Nanofibers[J]. J. Appl. Polym. Sci., 2017, 134: 45244–45255

Liu S L, Fan X S, He C B. Improving the Fracture Toughness of Epoxy with Nanosilica-rubber Core-shell Nanoparticles[J]. Compos. Sci. Technol., 2016, 125: 132–140

Kim H S, Khamis M A. Fracture and Impact Behaviours of Hollow Micro-sphere/epoxy Resin Composites[J]. Compos. Part A, 2001, 32: 1311–1317

Conradi M, Zorko M, Kocijan A, et al. Mechanical Properties of Epoxy Composites Reinforced with a Low Volume Fraction of Nanosilica Fillers[J]. Mater. Chem. Phys., 2013,137: 910–915

Swetha C, Kumar R. Quasi-static Uni-axial Compression Behaviour of Hollow Glass microspheres/epoxy Based Syntactic Foams[J]. Mater. Des., 2011, 32: 4152–4163

Wang L J, Yang X, Zhang J, et al. The Compressive Properties of Expandable Microspheres/epoxy Foams[J]. Compos. Part B, 2014, 56: 724–732

Woldesenbet E. Low Velocity Impact Properties of Nanoparticulate Syntactic Foams[J]. Mater. Sci. Eng. A, 2008, 496: 217–222

Kolay P K, Bhusal S. Recovery of Hollow Spherical Particles with Two Different Densities from Coal Fly Ash and Their Characterization[J]. Fuel, 2014, 117: 118–124

Acar I, Atalay M U. Recovery Potentials of Cenospheres from Bituminous Coal Fly Ashes[J]. Fuel, 2016, 180: 97–105

Wang C F, Liu J C, Du H Y, et al. Effect of Fly Ash Cenospheres on the Microstructure and Properties of Silica-based Composites[J]. Ceram. Int., 2012, 38: 4395–4440

Gu J, Wu G H, Zhang Q. Effect of Porosity on the Damping Properties of Modified Epoxy Composites Filled with Fly Ash[J]. Scripta Mater., 2007, 57: 529–532

Zyrkowski M, Neto R C, Santos L F, et al. Characterization of Fly-ash Cenospheres from Coal-fired Power Plant Unit[J]. Fuel, 2016, 174: 49–53

Li Q, Pang J F, Wang B, et al. Preparation, Characterization and Microwave Absorption Properties of Barium-ferrite-coated Fly-ash Cenospheres[J]. Adv. Powder Technol., 2013, 24: 288–294

Liu S M, Zhu J L, Guo X T, et al. Preparation of a-Fe2O3–TiO2/Fly Ash Cenospheres Photocatalyst and Its Mechanism of Photocatalytic Degradation[J]. Colloid Surf. A-Physicochem. Eng. Asp., 2015, 484: 434–440

Sharma J, Chand N, Bapat M N. Effect of Cenosphere on Dielectric Properties of Low Density Polyethylene[J]. Results in Physics., 2012, 2: 26–33

Deepthi M V, Sharma M, Sailaja R R N, et al. Mechanical and Thermal Characteristics of High Density Polyethylene-fly Ash Cenospheres Composites[J]. Mater. Des., 2010, 31: 2051–2060

Labella M, Zeltmann S E, Shunmugasamy V C, et al. Mechanical and Thermal Properties of Fly ash/vinyl Ester Syntactic Foams[J]. Fuel, 2014, 121: 240–249

Kumar B R B, Doddamani M, Zeltmann S E, et al. Processing of Cenosphere/HDPE Syntactic Foams Using an Industrial Scale Polymer Injection Molding Machine[J]. Mater. Des., 2016, 92: 414–423

Das A, Satapathy B K. Structural, Thermal. Mechanical and Dynamic Mechanical Properties of Cenosphere Filled Polypropylene Composites[J]. Mater. Des., 2011, 32: 1477–1484

Manakari V, Parande G, Doddamani M, et al. Dry Sliding Wear of Epoxy/ cenosphere Syntactic Foams[J]. Tribol. Int., 2015, 92: 425–438

Srivastava V K, Pawar A G. Solid Particle Erosion of Glass Fibre Reinforced Fly Ash Filled Epoxy Resin Composites[J]. Compos. Sci. Technol., 2006, 66: 3021–3028

Zhang L Y, Ma J. Effect of Coupling Agent on Mechanical Properties of Hollow Carbon Microsphere/phenolic Resin Syntactic Foam[J]. Compos. Sci. Technol., 2010, 70: 1265–1271

Yang R, Liu Y J, Wang K H, et al. Characterization of Surface Interaction of Inorganic Fillers with Silane Coupling Agents[J]. J. Anal. Appl. Pyrolysis., 2003, 70: 413–425

Derradji M, Ramdani N, Zhang T, et al. Mechanical and Thermal Properties of Phthalonitrile Resin Reinforced with Silicon Carbide Particles[J]. Mater. Des., 2015, 71: 48–55

Chen P, Ma F, Mei H F, et al. Erosive Wear Characteristics of High-alumina Cenospheres Filled Epoxy Resin Composites[J]. J. University of Sci. Technol. Beijing, 2014, 36(2): 218–225

Wang X, Wang L, Su Q, et al. Use of Unmodified SiO2 as Nanofiller to Improve Mechanical Properties of Polymer-based Nanocomposites[J]. Compos. Sci. Technol., 2013, 89: 52–60

Baheti V, Militky J, Mishra R, et al. Thermomechanical Properties of Glass Fabric/epoxy Composites Filled with Fly Ash[J]. Compos. Part B, 2016, 85: 268–276

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No.51305023) and the Fundamental Research Funds for the Central Universities of China (No.FRF-GF-17-B20)

Rights and permissions

About this article

Cite this article

Chen, P., Li, J. & Zhang, L. Analysis of mechanical characteristics of fly ash cenospheres reinforced epoxy composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 139–145 (2018). https://doi.org/10.1007/s11595-018-1798-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1798-8