Abstract

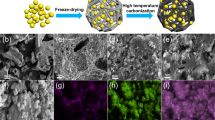

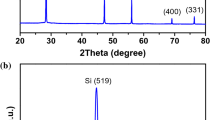

Two kinds of porous silicon (PS) were synthesized by magnesiothermic reduction of rice husk silica (RHS) derived from the oxidization of rice husks (RHs). One was obtained from oxidization/reduction at 500 °C of the unleached RHs, the other was synthesized from oxidization/reduction at 650 °C of the acidleached RHs. The structural difference of the above PS was compared: the former had a high pore volume (PV, 0.31 cm3/g) and a large specific surface area (SSA, 45.2 m2/g), 138 % and 17 % higher than the latter, respectively. As anode materials for lithium ion batteries, the former had reversible capacity of 1 400.7 mAh/g, 987 mAh/g lower than the latter; however, after 50 cycles, the former had 64.5 % capacity retention (907 mAh/g), which was 41.2 % higher than the latter (555.7 mAh/g). These results showed that the electrochemical performance of PS was significantly affected by its pore structures, and low reduction temperature played the key role in increasing its porosity, and therefore improving its cycling performance.

Similar content being viewed by others

References

Bruce P G, Scrosati B, Tarascon J M. Nanomaterials for Rechargeable Lithium Batteries[J]. Angew. Chem. Int. Ed., 2008, 47(16): 2930–2946

Key B, Bhattacharyya R, Morcrette M, et al. Real-Time NMR Investigations of Structural Changes in Silicon Electrodes for Lithium-Ion Batteries[J]. J. Am. Chem. Soc., 2009, 131(26): 9239–9249

Bang B M, Lee J -I, Kim H, et al. High-Performance Macroporous Bulk Silicon Anodes Synthesized by Template-Free Chemical Etching[J]. Adv. Energy Mater., 2012, 2(7): 878–883

Wu H, Chan G, Choi J W, et al. Stable Cycling of Double-walled Silicon Nanotube Battery Anodes through Solid-electrolyte Interphase Control[J]. Nat. Nanotechnol., 2012,7(5): 310–315

Jung D S, Ryou M -H, Sung Y J, et al. Recycling Rice Husks for Highcapacity Lithium Battery Anodes[J]. PNAS, 2013, 110(30): 12229–12234

Wen Z H, Lu G H, Cui S M, et al. Rational Design of Carbon Network cross-linked Si–SiC Hollow Nanosphere as Anode of Lithium-ion Batteries[J]. Nanoscale, 2014, 6(1): 342–351

Liu M P, Li C H, Du H B, et al. Facile Preparation of Silicon Hollow Spheres and Their Use in Electrochemical Capacitive Energy Storage[J]. Chem. Commun., 2012, 48(41): 4950–4952

Ge M, Fang X, Rong J, et al. Review of Porous Silicon Preparation and Its Application for Lithium-ion Battery Anodes[J]. Nanotechnology, 2013, 24(42): 422001

Yoo J K, Kim J S, Lee H J, et al. Porous Silicon Nanowires for Lithium Rechargeable Batteries[J]. Nanotechnology, 2013, 24(42): 424–008

Yoo J K, Kim J S, Jung Y S, et al. Scalable Fabrication of Silicon Nanotubes and their Application to Energy Storage[J]. Adv. Mater., 2012, 24(40): 5452–5456

Huang X K, Yang J, Ma S, et al. Controllable Synthesis of Hollow Si Anode for Long-Cycle-Life Lithium-Ion Batteries[J]. Adv. Mater., 2014, 26(25): 4326–4332

Bao Z H, Weatherspoon M R, Shian S, et al. Chemical Reduction of Three-dimensional Silica Micro-assemblies into Microporous Silicon Replicas[J]. Nature, 2007, 446(7132): 172–175

Hai N H, Grigoriants I, Gedanken A. Converting Stöber Silica and Mediterranean Sand to High Surface Area Silicon by a Reaction under Autogenic Pressure at Elevated Temperatures[J]. J. Phys. Chem. C, 2009, 113(24): 10521–10526

Favors Z, Wang W, Bay H H, et al. Scalable Synthesis of Nano-Silicon from Beach Sand for Long Cycle Life Li-ion Batteries[J]. Scientific Reports, 2014, 4: 05623

Krishnarao R V, Godkhindi M M. Distribution of Silica in Rice Husks and Its Effect on the Formation of Silicon Carbide[J]. Ceram. Int., 1992, 18(4): 243–249

Park B-D, Wi S G, Lee K H, et al. Characterization of Anatomical Features and Silica Distribution in Rice Husk Using Microscopic and Micro-analytical Techniques[J]. Biomass & Bioenergy, 2003, 25(3): 319–327

Wang W X, Martin J C, Fan X T, et al. Silica Nanoparticles and Frameworks from Rice Husk Biomass[J]. ACS Appl. Mater. Interfaces, 2012, 4(2): 977–981

Xing A, Tian S, Tang H, et al. Mesoporous Silicon Engineered by the Reduction of Biosilica from Rice Husk as a High-performance Anode for Lithium-ion Batteries[J]. RSC Adv., 2013, 3: 10145–10149

Liu N, Huo K F, McDowell M T, et al. Rice Husks as a Sustainable Source of Nanostructured Silicon for High Performance Li-ion Battery Anodes[J]. Sci. Rep., 2013, 3: 1919

Krishnarao R V, Subrahmanyam J, Kumar T J. Studies on the Formation of Black Particles in Rice Husk Silica Ash[J]. J. Eur. Ceram. Soc., 2001,21 (1): 99–104

Xiong L M, Sekiya E H, Sujaridworakun P, et al. Burning Temperature Dependence of Rice Husk Ashes in Structure and Property[J]. Journal of Metals, Materials and Minerals, 2009, 19(2): 95–99

Real C, Alcala M D, Criado J M. Preparation of Silica from Rice Husks[J]. J. Am. Ceram. Soc., 1996, 79(8): 2012–2016

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No. 51264016) and the Analysis and Testing Foundation of Kunming University of Science and Technology, China(No.20140967)

Rights and permissions

About this article

Cite this article

Liu, S., Liu, B., Yao, Y. et al. Effect of pore structures on the electrochemical performance of porous silicon synthesized from magnesiothermic reduction of biosilica. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 965–971 (2016). https://doi.org/10.1007/s11595-016-1476-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1476-7