Abstract

Light exposure of potatoes induces formation of both chlorophyll (greening) and of toxic glycoalkaloids (GAs). Greening leads to rejection by consumers and thus to food waste and economic loss. The aim of this study was to (1) study light sensitivity with respect to colour changes and GA development for different Norwegian grown potato cultivars stored at 20 °C and (2) evaluate the light protective effect of selected packaging materials on colour development in cv. Folva at 6 °C and 20 °C. Potatoes of seven cultivars were stored under LED illumination for 4 days at 20 °C. Changes in colour were measured during storage by Minolta Chroma meter and by visually assessing the limit for unacceptable change of colour. The tested cultivars became unacceptable at different times (24–60 h) and differed both in absolute colour values and relative changes of values. The levels of total glycoalkaloids in cultivars with and without light exposure did not correspond well to the changes in colour. Potatoes of cultivar Folva were packaged in materials with different light barrier properties, followed by LED illumination for 4 days at 20 °C and 18 days at 6 °C. None of the tested packaging types provided sufficient protection from light. All potatoes at 20 °C were unacceptably green after 2 days in light (16 h/day) while the potatoes at 6 °C were unacceptably green after 9 days. Packaging material for potatoes cv. Folva should aim for a total light transmittance below 0.02 W/m2 to avoid development of green colour during light exposure at 20 °C in grocery stores.

Similar content being viewed by others

Introduction

Development of green discolouration makes potatoes unacceptable for human consumption and is a major cause for food waste and economic losses. Greening, which is directly correlated to chlorophyll content (Grunenfelder et al. 2006), may be induced either by sunlight or artificial light and may occur both during the growing season and after harvest. In addition to harmless chlorophyll, light exposure of potato tubers will also induce formation of toxic glycoalkaloids (GAs). Although no metabolic connection has been established between the two processes, contents of GA may be partly predicted from colour changes (Tilahun et al. 2020). Green potatoes are generally considered unfit for human consumption and are identified as the primary reason for customers not purchasing potatoes (Tanios et al. 2020). For the Norwegian retail chains, the total potato waste in 2020 due to green potatoes was estimated to be 200 tons at a value of 250,000 Euro (Pål Westby, Norgesgruppen).

Chlorophyll production takes place in the cortical parenchyma tissues directly beneath the periderm (Petermann and Morris 1985). The process is found to be highly affected by cultivar, as well as several pre-harvest and post-harvest factors including light conditions and storage temperatures (Tanios et al. 2018).

Glycoalkaloids are a naturally occurring toxic group of secondary plant compounds, common in members of the Solanaceae family. They are biosynthesized through a series of enzymatic processes, with cholesterol as a major precursor for the final steps (Friedman et al. 1997). Their content is largely affected by cultivar and light exposure (Mekapogu et al. 2016) but may also be elevated by various pre- and postharvest stress factors (Friedman et al. 1997). Total glycoalkaloids (TGAs) in potatoes consist of more than 95% α-solanine and α-chaconine (Machado et al. 2007; Şengül et al. 2004). Oral daily doses in the range of 1–5 mg GAs/kg b.w. are marginally to severely toxic to humans depending on individual sensitivity of consumers (Ruprich et al. 2009). Hence, the safety level of TGA in potatoes has been established at 200 mg/kg fresh potato (Kaaber 1993; Machado et al. 2007; Nema et al. 2008). Levels above 200 mg/kg may potentially cause gastroenteric symptoms, coma and even death (Friedman 2006). Glycoalkaloids also influence the flavour of potatoes and cause bitterness in tubers at levels as low as 140 mg/kg. At low levels (below 100 mg/kg), glycoalkaloids can make a positive contribution to flavour (Jansky 2010). They may also possess a potential anticarcinogenic effect (Friedman 2015).

Different potato cultivars develop chlorophyll and green colour at different rates. Grunenfelder et al. (2006) reported differences in visible changes in colour between cultivars and developed separate subjective grading scales for different cultivars, based on objective measurements of chlorophyll and colour.

Several researchers have studied the effect of different light sources on the development of chlorophyll and GAs (Nema et al. 2008). Petermann and Morris (1985) studied the spectral responses for chlorophyll and GA synthesis in the tuber cv. Sebago in the visual light wavelength region from 400 to 700 nm. The chlorophyll synthesis showed maximum at 475 and 675 nm (blue region and red region, respectively), whereas the maximum synthesis of α-solanine and α-chaconine occurred at 430 nm and 650 nm. Minimum synthesis of chlorophyll was between 525 and 575 nm, while GA had minimum at 510–560 nm (green region). The differences support the assumption of two different biosynthesis pathways for chlorophyll and GAs. Virgin and Sundqvist (1992) found that the chlorophyll concentration in potato tubers (cv. Bintje) exposed to blue light (0.10 W/m2) was three times as high after 16 days of storage, compared to potatoes exposed to red light (0.38 W/m2). Experiments performed by the author (unpublished data) also demonstrated that potatoes exposed to blue light developed green colour faster than potatoes exposed to red light.

The combination of longer shop opening hours and increased use of light for marketing purposes has led to a higher extent of light exposure of the foods in the grocery stores. Today, low energy–consuming light emitting diodes (LEDs) are replacing fluorescent light tubes in many grocery stores. Larsen et al. (2019) measured irradiance from light sources used for illumination of potatoes in five grocery stores. They found the mean light irradiance to be 5.5 and 7.8 W/m2 for the fluorescent tubes and LED light, respectively. Larsen et al. (2019) also found that fluorescent tubes (7.5 W/m2) emitted 1.9 times more blue light (400–500 nm) than the LED lamps (7.7 W/m2), whereas the LED lamps emitted 2.5 more red light (620–680 nm) than the fluorescent tubes. Hence, a replacement of fluorescent tubes with LED lamps in the grocery stores may possibly reduce the illumination of the most detrimental blue wavelengths.

Light-protective packaging can limit greening of potatoes during light exposure (Eie and Larsen 2012; Martin and Sheppard 1983; Rosenfeld et al. 1995; Tanios et al. 2018). Among commonly used materials are opaque fibre materials and transparent or printed plastic materials with varying degrees of opacity. For potatoes stored under light in grocery stores, the level of light radiation, and in particular photosynthetically active radiation (PAR) reaching the potatoes, depends on the properties of the packaging materials. The wavelength regions from 400 to 500 nm (violet to blue) and from 620 to 680 nm (red) are of special interest (Petermann and Morris 1985). UV-blocking components are often used in packaging materials to inhibit negative responses to light exposure. However, since UV-light is outside the main light absorption regions for chlorophyll, packages with UV-barrier will not inhibit greening. This is also reported by French-Brooks et al. (2012). Eie and Larsen (2012) showed that potatoes stored in green-printed oriented polypropylene bags developed less greening than those under clear plastic film. Packaging bags with block-out print coverage on the face can reduce greening and extend shelf life (French-Brooks et al. 2012). The light-protective properties of the current potato packaging materials used for Norwegian potatoes are to our knowledge not sufficiently studied.

The aim of this study was to (1) study light sensitivity with respect to colour changes and GA development for different Norwegian grown potato cultivars stored at 20 °C and (2) evaluate the light-protective effect of selected packaging materials on colour development in cv. Folva at 6 °C and 20 °C.

Materials and Methods

The study was divided in two: Part A studied the chlorophyll and GA development in seven potato cultivars, and part B studied the effect of storage temperature and three selected packaging materials for one potato cultivar (Folva) on colour changes due to chlorophyll development. Potatoes of cv. Folva were selected for further experiments, due to being a major cultivar in Norway and having a light skin with apparent greening problems in retail. Bags of three packaging materials with different light protective properties were selected, based on previous screening of materials.

Light Sensitivity of Seven Potato Cultivars — Part A

The potatoes were obtained from experimental fields at NIBIO Apelsvoll (60° 42′ 8.6″ N 10° 51′ 53.5″ E), where they were all grown and harvested under similar conditions. According to common practice, and to avoid synthesis of chlorophyll and GA, potatoes were stored under dark conditions until the start of the experiment in October. Five medium-sized (50–60 g) tubers of the red-skinned potato cultivars Asterix, Nansen and Rutt and of the yellow-skinned cultivars Celandine, Folva, Hassel and Mandel were placed at 20 °C under light every 12th h, at 09.00 in the morning and at 21.00 in the evening. Within 4 days, 8 samples of each potato cultivar, each with five tubers, were exposed to light for 0, 12, 24, 36, 48, 60, 72 and 84 h, respectively. The light source was 24 h per day LED light of type GIR-1200 LED 7000 DALI 830 (Glamox AS, Oslo, Norway) with an irradiance level of 7.4 ± 0.6 W/m2 (2400 lx, see spectra in Fig. 5). This irradiance level was in accordance with the mean level previously measured by Larsen et al. (2019) in five grocery stores.

At day 4, visual assessments and colour measurements were performed for potatoes exposed to light for 0, 12, 24, 36, 48, 60, 72 and 84 h. The tubers were also photographed using a Samsung mobile camera at the end of the study. A visual determination of the limits for discolouration unacceptable for sale was performed by four skilled people daily working with potatoes. Instrumental colour values for CIE L* (lightness), a* (redness) and b* (yellowness) were obtained using a Minolta Chroma Meter CR-400 (Konica Minolta, Inc.) with an 8-mm viewing port, 2° viewer angle and illuminant D65. The instrument was calibrated against a white tile (L* = 97.35, a* = 0.03 and b* = 2.16). Two measurements at different points on the surface facing towards the light were made on all the tubers, giving ten readings for each cultivar at each light exposure time. Ten readings were assumed to be sufficient due to relatively even colour, shape and size of the potatoes.

Chroma C* and hue angle (h°) are considered to be more appropriate measures of colour than CIE L*, a* and b* (McGuire 1992). Hence, from L*, a* and b*, we calculated chroma (C*) and hue angle (h°) according to equations given in McGuire (1992) and Sant’Anna et al. (2013). Chroma expresses the vividness or saturation of a colour, whereas hue angle is the degree value that corresponds to the three-dimensional colour diagram (i.e. 0° for red, 90° for yellow, 180° for green and 270° for blue) as seen by the human eye (Sant’Anna et al. 2013). Colour difference (∆E*) is a numerical comparison of a sample’s colour to a standard and is calculated as the Euclidean distance between two points in a three-dimensional space defined by L*, a* and b* (Sant’Anna et al. 2013). The average L*, a* and b* values from potatoes measured at hour 0 (= 5 samples from each cultivar) were used as fixed standard values in the calculation of changes in colour difference during storage. In another trial with potatoes of cv. Folva exposed to light for 0 to 72 h, levels of L*, h° and ∆E* showed a strong correlation (R-squared values above 0.5) with measured concentrations of total chlorophyll (a and b) (L* = 0,54, a* = 0.75, h° = 0,78 and ∆E* = 0.83, unpublished data). This corresponds to a correlation coefficient between total chlorophyll and a* of − 0.87 (p < 0.001), whereas Tilahun et al. (2020) found a correlation coefficient of − 0.82 between total chlorophyll and Hunter a* (p < 0.001) for cvs Atlantic and Trent.

Analysis of α-solanine and α-chaconine was performed at Eurofins Food & Feed Testing Sweden (Lidköping) by a modified extraction method of Bodart et al. (2000). Five intact tubers per treatment (seven cultivars, with and without 36 h light treatment) were kept in total darkness for a few days from treatment until mincing and extraction with acidic methanol using first ultrasound and then mechanical shaking at room temperature. Quantification was done by HPLC with MS-detector in positive electrospray ionisation mode, with detection of chaconine at 852.5u and solanine at 868.5u. The HPLC was equipped with a C18 Hypersil Gold 100 × 2.2 mm, 3 µm column at 40 °C, and the mobile phase was (A) acetonitril and (B) 10 mM ammoniumacetat (pH 4.5). Elution was from 10% A to 95% A with a flow of 0.3 ml/min. Quantification was performed using a single quad MS detector against an external calibration curve at five points at 0.0016–0.6 mg/l.

Effect of Light Transmittance in Packaging Materials and Storage Temperature on Colour Changes in Folva Potatoes — Part B

Light Transmission and Transmittance Through Packaging Materials

Light irradiance is the power of electromagnetic radiation at a surface per unit area and can be expressed as W/m2. When testing packaging materials, a spectrophotometer is often used to measure light transmission. Light transmission expresses the percentage of monochromatic light which passes through the material at each wavelength from 200 to 900 nm. A spectroradiometer, measuring light transmittance, gives additional information as it measures both the total amount of light energy passing though the material (both in lux and W/m2) and spectral power distribution of the light able to pass through the material, given as W/m2 nm. Thus, spectral light transmittance more clearly illustrates how much light the packaged product is exposed to in each region of the visible light spectrum under the light source in use.

In initial studies, spectral light transmittance was measured for a range of different packaging materials commonly used for potato packaging. Transmittance was measured with a portable CL-500A illuminance spectrophotometer (Konica Minolta Sensing Europe B.V., Nordic Filial, Västra Frölunda, Sweden), detecting irradiance in the region 360 to 780 nm. The instrument was placed directly below the packaging material illuminated by a LED light source of type GIR-1200 LED 7000 DALI 830 (Glamox AS, Oslo, Norway), on a shelf 70 cm below the light source. The irradiance of the LED lamps was 7.8 W/m2 (equalling 36 µmol/m2 s). For each packaging material, light transmittance was measured at several points covering different printing inks, and two measurements were performed at each measuring point.

From this light transmittance screening, one plastic bag and two fibre-based bags were selected for further trials. Their light transmittances ranged from high, via medium to low. The plastic bag was a two-coloured (beige and turquoise) 50-µm oriented polypropylene (OPP) film sealed on a vertical flowpack machine, hereafter denoted high light transmittance (‘High-LT’). The fibre bag with medium light transmittance (hereafter denoted ‘Mid-LT’) was made of one layer of light-coloured paper with areas of grey, beige and brown printing on the outside. The fibre bag with the lowest light transmittance (hereafter denoted ‘Low-LT’) was made of one layer of paper with black printing on the inside and light and black printing on the outside. Approximately one-third of the outside area of this bag was covered with black printing giving the highest level of light protection in this study.

Light transmission of the selected plastic bag and fibre-based bags was measured by a Lambda 800 UV/VIS spectrophotometer with an integrated sphere (Perkin Elmer Instruments, Norwalk, Conn., USA).

Light Exposure at 20 and 6 °C of Potatoes Packaged in Different Materials

Nine medium-sized (50 to 60 g) potatoes of cv. Folva were placed in low plastic trays. A marker was used to mark a circle of about 2 cm in diameter to follow the colour changes at the same point on the potatoes during storage. The plastic trays were placed flat into the selected plastic pouch or fibre-based bags as described above, before closing of the packages by folding the edge. The reference samples included nine medium-sized (50 to 60 g) uncovered potatoes (denoted ‘No-P’) and nine potatoes packaged in aluminium foil with no light transmittance (‘Alum’). The reference samples and the plastic pouch and paper bags were run in three replicates (3 × 9 potatoes). The potatoes were placed on the shelves approximately 70 cm below the LED light source with a mean irradiance of 7.2 W/m2 and at 7.5 W/m2 at 20 and 6 °C, respectively. The LED light source was of type GIR-1200 LED 7000 DALI 830 (Glamox AS, Oslo, Norway). The light was turned on at 07.00 and shut off at 23.00 (16 h/day), simulating a realistic time of illumination in grocery stores.

Colour Measurement During Illuminated Storage

Preliminary experiments have shown that the colour changes for cv. Folva under light exposure occurred within 4 days at 20 °C and within 18 days at 6 °C. Hence, the potatoes at 20 °C were stored for 4 days, with colour measurements at days 1, 2, 3 and 4, whereas the potatoes at 6 °C were stored under light conditions for 18 days with colour measurements at days 4, 9, 14 and 18. Instrumental colour was measured and calculated according to the description in “Light Sensitivity of Seven Potato Cultivars — Part A”. The average L*, a* and b* values from 54 reference potatoes (= all potatoes in aluminium foil at day 0) were used as fixed values in the calculation of colour difference during storage.

Statistical Analysis

Analysis of variance (ANOVA) was performed for the packaging trial dataset in Part B (α = 0.05) using general linear model in Minitab 17 Statistical Software (Minitab Inc., State College, PA, USA). The datasets for 20 °C and 6 °C were analysed separately, and differences between means were determined by Tukey’s multiple comparison test.

Results and Discussion

Light Sensitivity of Seven Potato Cultivars — Part A

The visual colour changes of four potato varieties stored for 0 to 84 h under LED illumination are presented in Fig. 1, showing the different visual effects of time on colour of various potato cultivars.

The red-skinned cv. Asterix (Fig. 1a) showed a large increase in hue angle, going from red to a brownish colour, whereas the yellow cv. Folva (Fig. 1b) increased in hue angle from 80 (yellow-green) to 94 (green-yellow). The yellow cv. Celandine (Fig. 1c) showed the least changes in all colour parameters during light exposure, whereas the yellow cv. Mandel (Fig. 1d) was the only cultivar where change in chroma value, going from yellow to a greyish colour, was the most important colour parameter.

Chroma metre values for lightness (L*; Fig. 2), calculated hue angle (h°; Fig. 3) and total colour difference (∆E*; Fig. 4) are presented for the red-skinned potato cultivars Asterix, Nansen and Rutt and the yellow cultivars Celandine, Folva, Hassel and Mandel, placed at 20 °C under continuous light every 12th h for 4 days.

After illumination for 0, 12, 24, 36, 48, 60, 72 and 84 h, L* decreased most over time for cv. Rutt and for the yellow cultivars (Fig. 2), while hue angle increased most for the red cultivars (Fig. 3). The change in ∆E* was highest for cvs. Asterix and Mandel and lowest for cv. Celandine (Fig. 4). Table 1 summarizes the hours until each cultivar was considered unacceptable for sale by visual evaluation, and colour values at start (0 h) and at the time the potatoes were considered unacceptable for sale. In addition, total glycoalkaloids (TGAs) are given at 0 and 36 h.

Cv. Celandine was the cultivar with the longest period under illumination before being considered unacceptable for sale (60 h), whereas cv. Mandel was considered unacceptable after just 24 h (Table 1). Cv. Nansen was unacceptable after 48 h of illumination, while the four last cultivars had unacceptable discolouration after 36 h.

For all cultivars except Mandel, the largest change during illumination was observed in h° (bold in Table 1), indicating a change in actual colour, rather than just intensity or lightness. The increase of h° was most pronounced for cultivars with red skin. Red potatoes mostly changed from bright purple to more brownish, while most yellow cultivars changed to green. In contrast, the yellow cultivar Mandel increased in darkness (lower L*) and became duller and more greyish in colour (lower C*). L* was also significantly reduced for Hassel. For the darkest cultivars, Asterix and Nansen, L* remained largely unchanged. C*, which indicates colour intensity or brightness, was most reduced for cv. Asterix, followed by cvs. Mandel, Nansen and Hassel. Calculations of total colour change (∆E*) showed that cv. Celandine had the lowest ∆E*, while one red (Asterix) and one yellow cultivar (Mandel) had the largest change of ∆E* at the time of becoming unacceptable (Fig. 3).

These data show differences among cultivars in both absolute values and in changes of values for L*, C*, h° and ∆E before reaching an unacceptable colour. This indicates that a separate set of indicators for unacceptable greening must be found for each cultivar.

These results are in accordance with the results of Grunenfelder et al. (2006), who reported differences in visible changes in colour between cultivars and developed separate subjective grading scales for different cultivars, based on objective measurements of chlorophyll and colour. These grading scales were also successfully used for the relevant cultivars to assess the levels of greening in the retail marked (Grunenfelder 2005).

All the cultivars except cv. Mandel showed an increase in total glycoalkaloids after light exposure for 36 h. For the red cv. Asterix and the two yellow cultivars Folva and Hassel (marked with bold in Table 1), the TGA levels after 36 h were above the recommended max-level of 200 mg/kg fresh weight. After 36 h of light exposure, however, these cultivars were also considered unacceptable due to greening. Major differences in levels and changes in TGA by light, as well as heat and wounding, were also found by Petersson et al. (2013). They found mean TGA for 21 cultivars, including cultivars Asterix and Folva, to be 127 mg/kg before treatment and 317 mg/kg after 8 days in white fluorescent light at 22 °C. While cv. Folva had the highest levels and highest increase caused by light exposure in our experiments, Petersson et al. (2013) found cv. Asterix to have higher levels and increase. Grunenfelder (2005) confirmed variability in the extent of light-induced TGA development among the cultivars tested, but with TGA concentration in the flesh of even the greenest tubers well below the limit of 200 mg/kg.

Effect of Light Transmittance in Packaging Materials and Storage Temperature on Colour Changes in Folva Potatoes — Part B

Light Transmission and Transmittance Through Packaging Materials

Light transmission (%) (Fig. 5a) and spectral light transmittance (W/m2 nm) (Fig. 5b) was measured for three packaging materials with high, medium (mid) and low light transmittance (LT). The regions marked in Fig. 5 are the blue and red regions, where most of the light is absorbed by chlorophyll a and b (LED Grow Lights HQ 2021) and most chlorophyll and glycoalkaloids are synthetized, according to Petermann and Morris (1985).

The plastic pouches had the highest light transmission and transmittance; the three-coloured paper bags with areas of grey, beige, and brown had medium levels and the two-coloured paper bags with black coloured inner layer had the lowest light transmission and transmittance. Light transmission and transmittance were influenced both by print colour and by type of packaging material. Compared to the transmittance curve for the LED light, even the most transparent material (High-LT-beige) absorbed some light energy showing a lower transmittance than LED light at all wavelengths.

The order of the materials and print colours were very similar for both light transmission (Fig. 5a) and light transmittance (Fig. 5b), with High-LT-Beige as the one with highest transmission and transmittance and Low LT-black with the lowest. The order within the blue region (400–495 nm) was slightly different from the red region (620–710 nm) since the turquoise colour of the plastic bag (High-LT-turquoise) absorbed light in the red region. Our results show that none of the materials totally absorbed all light, not even the fibre-based bag with black inside and black printing (Low-LT-black). However, since all the bags consisted of areas with different print colours, it was difficult to estimate the total amount of light passing through to the potatoes in each package. In this respect, it is easier to work with uniform materials with one type of material and one colour.

Light Exposure at 20 and 6 °C of Potatoes Packaged in Different Materials

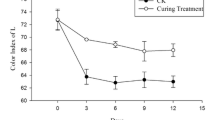

Colour (L*, a* and b*; converted to L*, C* and h°) was measured at the same point on the potatoes after 1, 2, 3 and 4 days at 20 °C and 4, 9, 14 and 18 days of illuminated storage at 6 °C. Changes in total colour difference (ΔE*) were calculated from L*, a* and b* values. Relatively small changes and differences were detected for chroma (C*), and hence, only the results for lightness (L*), hue angle (h°) (Fig. 6) and total colour change (∆E*) (Fig. 7) are presented for 20 and 6 °C.

Mean lightness (L*) and hue angle (h°) values for potatoes cv. Folva packaged in different materials and stored under LED illumination (16 h/day) for 4 days at 20 °C (top) and 18 days at 6 °C (bottom). The potatoes were packaged in aluminium foil (Alum) and bags with high (High-LT), medium (Mid-LT) and low (Low-LT) light transmittance. Samples marked with No-P were reference potatoes without packaging. Packaging samples (lines) with different letters are significantly different

Total colour difference (∆E*) mean values for potatoes cv. Folva packaged in different materials and stored under LED illumination (16 h/day) for 4 days at 20 °C and 18 days at 6 °C. The potatoes were packaged in aluminium foil (Alum) and bags with high (High-LT), medium (Mid-LT) and low (Low-LT) light transmittance. Samples marked with No-P were reference potatoes without packaging. Packaging samples (bars) with different letters are significantly different

The levels of reduction in L* and increase in h° were quite similar for packaged samples after 4 days at 20 °C as for 18 days at 6 °C, indicating that the rate of greening was four times faster at room temperature than at cold storage. The effect of temperature is also stated in a review by Tanios et al. (2018). Edwards and Cobb (1997) stored potato tubers (cv. King Edward) at 5, 10, 20 and 25 °C for up to 8 days in light or darkness. Accumulation of chlorophylls causing maximal greening was highest at 20 °C, which is comparable with temperatures found in most retail stores. Hence, Folva potatoes should be displayed under lower temperatures in retail stores to reduce greening rates and consequently extend shelf-life.

Folva potatoes were rated as unacceptable when L* had changed by − 1.6, h° by + 9.0 and ΔE* by + 6.0 (Table 1). Potatoes in aluminium foil did not show any noticeable colour changes at neither 20 nor 6 °C. At 20 °C, unacceptable colour developed within the second day for all the packaged samples and potatoes without packaging, although the potatoes in the package with the lowest light transmittance (Low-LT) had significantly less colour change than the other three. At 6 °C, all the packaged potatoes were rated as unacceptable green after 9 days under light. Surprisingly, the unpackaged potatoes at 6 °C showed less greening than the packaged potatoes and were not rated as unacceptable green after 14 days in light (ΔE* = 5.75, being below 6.0 in Table 1). We do not have a reasonable explanation for this unexpected finding, and this phenomenon will be further studied.

None of the packaging materials, not even the fibre-based bag with black inside and very low light transmission, could inhibit the development of greening within 2 days at 20 °C or 9 days at 6 °C, respectively. Martin and Sheppard (1983) concluded that none of the transparent or semi-transparent packaging materials offered any improvement over no packaging for the two potato cultivars used in their study. They measured light transmittance through different packaging materials using a Lambda Instrument Company Quantum Sensor measuring PAR in the wavelength region 400–700 nm. The opaque brown paper packaging with a light transmittance of 0.1 W/m2, being slightly lower than the light transmittance of the Low-LT sample in our study, gave the most efficient inhibition of chlorophyll development. However, a small increase in chlorophyll (from approximately 400 µl/ml at start of trial to 650 µl/ml after 5 days in light) was also observed in this brown paper packaging, although no information is given if this increase was visually noticeable or not. For the yellow-skinned cv. White Rose (Grunenfelder et al. 2006), which seems to have a similar greening development scale as cv. Folva, this small increase in chlorophyll was visually detectable.

From our packaging trials, we may conclude that packaging materials for potatoes, under normal lightning conditions used in grocery stores, should have a light transmittance below 0.1 W/m2 to avoid greening within 2 days at 20 °C or 9 days at 6 °C. Included in the basis for this conclusion is an additional experiment (results not presented), where Folva potatoes were packaged in the fibre bag with lowest light transmittance (Low-LT) and exposed to lower light intensity (irradiance reduced from 7.2 to 2.9 W/m2) for 10 days. Additional potatoes were also packaged in a double-layered black-coloured plastic garbage bag and stored under LED light (7.8 W/m2) for 11 days. These results demonstrated that only the double-layered black-coloured plastic material (light transmittance 0.02 W/m2) protected the potatoes against green colour development. After 11 days of illumination, the colour of these potatoes was almost as light as the colour of the potatoes stored for 18 days in aluminium foil. Nyankanga et al. (2018) found that greening of potatoes did not occur in black plastic bags, whether perforated or non-perforated.

Conclusion

Under light exposure, potatoes develop chlorophyll, giving a green flesh and a green or brownish discolouration of the peel, depending on the nature and colour of the peel. Such a discolouration makes potatoes unacceptable for human consumption and contributes significantly to food waste and economic losses.

Different potato cultivars develop various forms of discolouration and at different rates. The first of the six cultivars, Mandel, reached unacceptable levels of discolouration after 24 h under LED light at 20 °C, while the last cultivar, Celandine, was found to be unacceptable after 60 h. Red potatoes mainly changed in hue angle (h°), to a less clear red colour. Most yellow cultivars turned green, with an increase in h° and a reduction in lightness (L*). In the exception, yellow-skinned cv. Mandel, the peel turned dark (lower L*) and dull (lower C*), rather than actual green. The lack of correlation among cultivars between absolute values and relative changes of values for L*, C*, h° and ∆E before reaching an unacceptable colour, indicates that separate critical levels for unacceptable greening must be found for each cultivar. The levels of total glycoalkaloids (TGA) in cultivars with and without light exposure varied among cultivars but did not correspond well to the changes in colour.

Cv. Folva was stored under LED light at 20 and 6 °C in packages with three different light protective properties. The rate of greening was four times faster at room temperature than at cold storage. Hence, Folva potatoes should be displayed under lower temperatures in retail stores to reduce greening rates and consequently extend shelf-life.

None of the tested packaging types gave major protection from light, and the potatoes at 20° C were unacceptably green after 2 days in light (16 h/day) while the potatoes at 6° C were unacceptably green after 9 days in light. When stored at 20 °C, the potatoes in the package with lowest light transmittance had significantly less colour change than the potatoes in the other two packages and the potatoes without packaging. When stored at 6 °C, the potatoes without packaging became significantly less green than the packaged ones.

Packaging materials for potatoes like cv. Folva should have a total light transmittance lower than 0.02 W/m2 to avoid development of green colour during light exposure at 20 °C in the grocery stores. Such low levels were in this experiment only obtained when covered by double-layered black-coloured plastic and by aluminium.

Data Availability

Data underlying presented results are available on request.

Change history

14 November 2022

Missing Open Access funding information has been added in the Funding Note.

References

Bodart P, Kabengera C, Noirfalise A, Hubert P, Angenot L (2000) Determination of α-solanine and α-chaconine in potatoes by high-performance thin-layer chromatography/densitometry. J AOAC Int 83:1468–1473

Edwards EJ, Cobb AH (1997) Effect of temperature on glycoalkaloid and chlorophyll accumulation in potatoes (Solanum tuberosum L. cv. King Edward) stored at low photon flux density, including preliminary modeling using an artificial neural network. J Agric Food Chem 45:1032–1038. https://doi.org/10.1021/jf9607324

Eie T, Larsen H (2012) The effect of packaging light barrier on greening and solanine formation in Sava cultivar potatoes (Solanum tuberosum L.) stored at 5 and 15 °C under fluorescent light. Paper presented at the eighteenth IAPRI world packaging conference, June 17 to June 2, 2012. In: Book of proceedings, pp. 149–155

French-Brooks J (2012) Reducing supply chain and consumer potato waste. WRAP (http://www.wrap.org.uk/) Research Report. 50pp

Friedman M (2006) Potato glycoalkaloids and metabolites: roles in the plant and in the diet. J Agric Food Chem 54:8655–8681

Friedman M (2015) Chemistry and anticarcinogenic mechanisms of glycoalkaloids produced by eggplants, potatoes, and tomatoes. J Agric Food Chem 63:3323–3337

Friedman M, McDonald GM, Filadelfi-Keszi M (1997) Potato glycoalkaloids: chemistry, analysis, safety, and plant physiology. CRC Crit Rev Plant Sci 16:55–132

Grunenfelder L (2005) Physiological studies of light-induced greening in fresh market potatoes. Department of Horticulture and Landscape Architecture. Dissertation. Washington State University

Grunenfelder L, Hiller LK, Knowles NR (2006) Color indices for the assessment of chlorophyll development and greening of fresh market potatoes. Postharvest Biol Tec 40:73–81. https://doi.org/10.1016/j.postharvbio.2005.12.018

Jansky SH (2010) Potato flavor. Am J. Potato Res 87:209–217 ISSN: 1874-9380

Kaaber L (1993) Glycoalkaloids, green discoloration and taste development during storage of some potato varieties (Solanum tuberosum L.). Norwegian Journal of Agricultural Sciences (Norway) 7:221–229

Larsen H, Sanden KW, Molteberg EL (2019) Light transmittance in packaging materials and effect of light barrier on greening of Folva cultivar potatoes (Solanum tuberosum L.) stored at 20 °C under LED light. In: Rt K (ed) 29th IAPRI Symposium on Packaging Serving Society – innovative perspectives on packaging. University of Twente, Twente, pp 399–407

LED Grow Lights HQ (2021) Chlorophyll & other photosensitives. http://www.ledgrowlightshq.co.uk/chlorophyll-plant-pigments/. Accessed 3 September 2021.

Machado RM, Toledo MCF, Garcia LC (2007) Effect of light and temperature on the formation of glycoalkaloids in potato tubers. Food Control 18:503–508. https://doi.org/10.1016/j.foodcont.2005.12.008

Martin S, Sheppard R (1983) Effect of different packaging materials and light exposure times on chlorophyll concentration in 2 cultivars of potato. New Zeal J Exp Agr 11:63–67. https://doi.org/10.1080/03015521.1983.10427729

McGuire RG (1992) Reporting of objective color measurements. HortScience 27:1254–1255 ISSN: 0018-5345

Mekapogu M, Sohn H-B, Kim S-J, Lee Y-Y, Park H-M, Jin Y-I, Hong S-Y, Suh J-T, Kweon K, Jeong J-C (2016) Effect of light quality on the expression of glycoalkaloid biosynthetic genes contributing to steroidal glycoalkaloid accumulation in potato. Am J Potato Res 93:264–277

Nema PK, Ramayya N, Duncan E, Niranjan K (2008) Potato glycoalkaloids: formation and strategies for mitigation. J Sci Food Agric 88:1869–1881. https://doi.org/10.1002/jsfa.3302

Nyankanga RO, Murigi WW, Shibairo SI (2018) Effect of packaging material on shelf life and quality of ware potato tubers stored at ambient tropical temperatures. Potato Res 61:283–296. https://doi.org/10.1007/s11540-018-9377-0

Petermann JB, Morris SC (1985) The spectral responses of chlorophyll and glycoalkaloid synthesis in potato tubers (Solanum tuberosum). Plant Sci 39:105–110. https://doi.org/10.1016/0168-9452(85)90100-1

Petersson EV, Arif U, Schulzova V, Krtková V, Hajšlová J, Meijer J, Andersson HC, Jonsson L, Sitbon F (2013) Glycoalkaloid and calystegine levels in table potato cultivars subjected to wounding, light, and heat treatments. J Agric Food Chem 61:5893–5902

Rosenfeld H, Sundell H, Lea P, Ringstad M (1995) Influence of packaging materials and temperature on the glycoalkaloid content of potato tubers. Food Res Int 28:481–484. https://doi.org/10.1016/0963-9969(96)81395-0

Ruprich J, Rehurkova I, Boon P, Svensson K, Moussavian S, Van der Voet H, Bosgra S, Van Klaveren J, Busk L (2009) Probabilistic modelling of exposure doses and implications for health risk characterization: glycoalkaloids from potatoes. Food Chem Toxicol 47:2899–2905

Sant’Anna V, Gurak PD, Marczak LDF, Tessaro IC (2013) Tracking bioactive compounds with colour changes in foods–a review. Dyes Pigm 98:601–608. https://doi.org/10.1016/j.dyepig.2013.04.011

Şengül M, Keleş F, Keleş M (2004) The effect of storage conditions (temperature, light, time) and variety on the glycoalkaloid content of potato tubers and sprouts. Food Control 15:281–286. https://doi.org/10.1016/S0956-7135(03)00077-X

Tanios S, Eyles A, Corkrey R, Tegg RS, Thangavel T, Wilson CR (2020) Quantifying risk factors associated with light-induced potato tuber greening in retail stores. PLoS ONE 15(9):e0235522

Tanios S, Eyles A, Tegg R, Wilson C (2018) Potato tuber greening: a review of predisposing factors, management and future challenges. Am J Potato Res 95:248–257. https://doi.org/10.1007/s12230-018-9648-y

Tilahun S, An HS, Hwang IG, Choi JH, Baek MW, Choi HR, Park DS, Jeong CS (2020) Prediction of α-solanine and α-chaconine in potato tubers from Hunter color values and VIS/NIR spectra. J Food Qual: 2020. https://doi.org/10.1155/2020/8884219

Virgin HI, Sundqvist C (1992) Pigment formation in potato tubers (Solanum tuberosum) exposed to light followed by darkness. Physiol Plant 86:587–592. https://doi.org/10.1111/j.1399-3054.1992.tb02174.x

Acknowledgements

We wish to thank Bama for the support of potatoes and packaging materials, Magnhild Seim Grøvlen for performing measurements of light transmittance in packaging materials and Karen Wahlstrøm Sanden for handling of samples for analyses and colour measurements.

Funding

Open access funding provided by Nofima the food research institute, Norwegian Institute of Food, Fisheries and Aquaculture Research. The initial work in this study at Nofima and NIBIO was funded by Grofondet (no: 180016). For H. Larsen, the finalising work was performed as a part of the strategic programme “FutureFoodControl” at Nofima funded by Foundation for Research Levy on Agricultural Products (FFL, no: 314743). For author E.L. Molteberg, no extra external funding was received.

Author information

Authors and Affiliations

Contributions

Both authors contributed to the study conception and design. Material preparation and data collection from light experiments were performed by H. Larsen while E.L. Molteberg contributed with materials, visual analyses and analyses of TGA. Both authors contributed to data interpretation. The first draft of the manuscript was written by H. Larsen while both authors worked together to revise and approve the final manuscript.

Corresponding author

Ethics declarations

Consent for Publication

Yes.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Larsen, H., Molteberg, E.L. Discolouration of Potato Tubers Under Retail Light: Cultivar Variations and Effect of Different Packaging Materials for Folva Potatoes Stored at 20 and 6 °C. Potato Res. 66, 507–523 (2023). https://doi.org/10.1007/s11540-022-09585-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11540-022-09585-6