Abstract

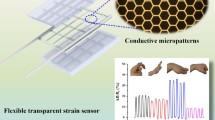

At present, study on dynamic tensile properties and atomic chain fabrication of single nanowire, for understanding its dynamic tensile properties and unique physical properties of atomic chain to fabricate atom scale devices, is one of frontier research issues in nanoscale science. However, how to assemble single nanowire on a tensible microstructure becomes one of the most difficult problems, which severely restricts the development of this research field. In this paper, after the ultrahigh tensible microelectrode chip is fabricated by MEMS technology, hexamethyldisilazane is utilized to improve hydrophobicity of the chip, and then a microdroplet dielectrophoresis experimental platform and technology is developed to assemble single nanowire on the sensible microelectrode. Experimental results show that accurate and efficient assembly of single Cu nanowire is realized, which contribute greatly to the further research of dynamic tensile properties and atomic chain fabrication. And for guiding the assembly experiments, finite element technology is also utilized to analyze the local microelectro field around the microelectrodes during dieletrophoresis experiments.

Similar content being viewed by others

References

Fasth C, Fuhrer A, Samuelson L et al (2007) Direct measurement of the spin–orbit interaction in a two-electron InAs nanowire quantum dot. Phys Rev Lett 98:266801

Nilsson HA, Caroff P, Thelander C et al (2009) Giant, level-dependent g factors in InSb nanowire quantum dots. Nano Lett 9:3151–3156

Romeo L, Roddaro S, Pitanti A et al (2012) Electrostatic spin control in InAs/InP nanowire quantum dots. Nano Lett 12:4490–4494

Hochbaum AI, Fan R, He RR et al (2005) Controlled growth of Si nanowire arrays for device integration. Nano Lett 5:457–460

Huang Y, Lieber CM (2004) Integrated nanoscale electronics and optoelectronics: exploring nanoscale science and technology through semiconductor nanowires. Pure Appl Chem 76:2051–2068

Li Y, Qian F, Xiang J et al (2006) Nanowire electronic and optoelectronic devices. Mater Today 9:18–27

Ohnishi H, Kondo Y, Takayanagi K (1998) Quantized conductance through individual rows of suspended gold atoms. Nature 395:780–783

Smogunov A, Dal Corso A, Delin A et al (2008) Colossal magnetic anisotropy of monatomic free and deposited platinum nanowires. Nat Nanotechnol 3:22–25

Sokolov A, Zhang C, Tsymbal EY et al (2007) Quantized magnetoresistance in atomic-size contacts. Nat Nanotechnol 2:171–175

Weber B, Mahapatra S, Ryu H et al (2012) Ohm’s law survives to the atomic scale. Science 335:64–67

Liu XM, Yang XB, Wei YG (2012) Yielding behavior of copper nanowire in the presence of vacancies. Sci China Phys Mech Astron 55:1010–1017

Yang ZY, Jiao FF, Lu ZX et al (2013) Coupling effects of stress and ion irradiation on the mechanical behaviors of copper nanowires. Sci China Phys Mech Astron 56:498–505

Zhu Y, Espinosa HD (2005) An electromechanical material testing system for in situ electron microscopy and applications. Proc Natl Acad Sci USA 102:14503–14508

Morgan H, Hughes MP, Green NG (1999) Separation of submicron bioparticles by dielectrophoresis. Biophys J 77:516–525

Liu YL, Chung JH, Liu WK et al (2006) Dielectrophoretic assembly of nanowires. J Phys Chem B 110:14098–14106

Tian XJ, Wang YC, Yu HB et al (2009) Di-electrophoresis assembly and fabrication of SWCNT field-effect transistor. Chin Sci Bull 54:4451–4457

Vijayaraghavan A, Blatt S, Weissenberger D et al (2007) Ultra-large-scale directed assembly of single-walled carbon nanotube devices. Nano Lett 7:1556–1560

Hermanson KD, Lumsdon SO, Williams JP et al (2001) Dielectrophoretic assembly of electrically functional microwires from nanoparticle suspensions. Science 294:1082–1086

Zhang D, Wang R, Wen M et al (2012) Synthesis of ultralong copper nanowires for high-performance transparent electrodes. J Am Chem Soc 134:14283–14286

Hertl W, Hair ML (1971) Reaction of hexamethyldisilazane with silica. J Phys Chem US 75:2181–2185

Chan RHM, Fung CKM, Li WJ (2004) Rapid assembly of carbon nanotubes for nanosensing by dielectrophoretic force. Nanotechnology 15:S672–S677

Li JQ, Zhang Q, Peng N et al (2005) Manipulation of carbon nanotubes using AC dielectrophoresis. Appl Phys Lett 86:153116–153118

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51375477 and 61375091) and the CAS FEA International Partnership Program for Creative Research Teams.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Huang, C., Zeng, H., Tian, X. et al. Single Cu nanowire assembled by microdroplet dielectrophoresis on ultrahigh tensible microelectrodes. Chin. Sci. Bull. 59, 577–584 (2014). https://doi.org/10.1007/s11434-013-0065-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-013-0065-9