Abstract

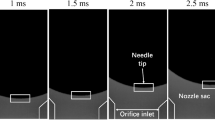

The design of fuel nozzle orifices at micrometer scales is crucial for generating desired fuel spray patterns, and consequently optimizing fuel combustion and emission in internal combustion engines. Although there have been several recent advancements in the characterization of orifice internal geometries, quantitative studies on the orifice internal wall surface characteristics are still challeges due to the lack of effective measuring methods. A new method for quantifying the internal wall surface characteristics of fuel nozzle micro-orifices is presented in this study to achieve a better understanding and prediction of spray characteristics: Firstly, by using the synchrotron X-ray micro CT technology, a three-dimensional digital model of the fuel nozzle tip was constructed. Secondly, a data post-processing technique was then applied to unfold the orifice internal wall surface to a flat base plane. Finally, the conventional surface characteristic quantification techniques can be used to evaluate the wall surface characteristics. Two diesel nozzles with identical orifice geometry design but different hydraulic grinding time were measured using this method. One nozzle was hydro-ground for 2 s while the other was not. The internal wall surfaces of the two orifices were successfully unfolded to base planes and their surface characteristics were respectively analyzed. The surface fluctuation data were perfectly reproduced by a Gaussian distribution function. The standard deviations of the distribution demonstrate the fluctuation range and the distribution of the entire surface fluctuation profiles. As an effective parameter to evaluate the hydraulic grinding process and the spray behaviors, the standard deviation was considered feasible for the analysis of the orifice internal wall surface characteristics.

Similar content being viewed by others

References

Yoshikawa S, Furusawa R, Arai M, et al. Optimizing spray behavior to improve engine performance and to reduce exhaust emissions in a small D.I. diesel engine. SAE Technical Paper 890463, 1989

Agarwal A K, Gupta J G, Maurya R K, et al. Spray evolution, engine performance, emissions and combustion characterization of Karanja biodiesel fuelled common rail turbocharged direct injection transportation engine. Int J Engine Res, 2016, 17: 1092–1107

Som S, Ramirez A I, Longman D E, et al. Effect of nozzle orifice geometry on spray, combustion, and emission characteristics under diesel engine conditions. Fuel, 2011, 90: 1267–1276

Han D, Duan Y, Wang C, et al. Experimental study on the two stage injection of diesel and gasoline blends on a common rail injection system. Fuel, 2015, 159: 470–475

Duan Y, Han D, Li P, et al. Experimental study on injection and macroscopic spray characteristics of ethyl oleate, jet fuel, and their blend on a diesel engine common rail system. Atomiz Spr, 2015, 25: 777–793

Ohrn T R, Senser D W, Lefebvre A H. Geometrical effects on discharge coefficients for plain-orifice atomizers. Atomiz Spr, 1991, 1: 137–153

Payri R, Salvador F J, Gimeno J, et al. Diesel nozzle geometry influence on spray liquid-phase fuel penetration in evaporative conditions. Fuel, 2008, 87: 1165–1176

Camille H, Jean-Bernard B, Xandra M, et al. Influence of Nozzle geometry on spray shape, particle size, spray velocity and Air entrainment of high-pressure Diesel spray. In: Proceddings of THIESEL 2010—Conference on Thermo-and Fluid Dynamic Processes in Diesel Engines. 2010, Valencia, 2010

Moon S, Gao Y, Park S, et al. Effect of the number and position of nozzle holes on in- and near-nozzle dynamic characteristics of diesel injection. Fuel, 2015, 150: 112–122

Huang W D, Wu Z J, Gong H F, et al. Effect of nozzle geometry on macroscopic behavior of diesel spray in the near-nozzle field. SAE Paper 2013–01–1587, 2013

Wu Z, Gao Y, Gong H, et al. Evaluation and optimization of the structural parameter of diesel nozzle basing on synchrotron radiation imaging techniques. J Inst, 2016, 11: C04004

Li Y, Guo H, Ma X, et al. Experimental study of effect of nozzle diameter on near-field spray behavior of diesel sprays in non-evaporating conditions. SAE Paper 2014–01–1405, 2014

Tu P W, Xu H, Srivastava D K, et al. Numerical investigation of GDI injector nozzle geometry on spray characteristics. SAE Paper 2015–01–1906, 2015

Benajes J, Pastor J V, Payri R, et al. Analysis of the influence of diesel nozzle geometry in the injection rate characteristic. J Fluids Eng, 2004, 126: 63–71

Eeshotko M, Boldman D E, Ehlers R C. Effects of eoughness on heat transfer in conical nozzles. In: Proceddings of Augmentation of Convective Heat and Mass Transfer, American Society of Mechanical Engineers, Winter Annual Meeting. New York, 1970. 63–69

Xu M, Zhang Y, Zeng W, et al. Flash boiling: Easy and better way to generate ideal sprays than the high injection pressure. SAE Int J Fuels Lubr, 2013, 6: 137–148

Echouchene F, Belmabrouk H, Le Penven L, et al. Numerical simulation of wall roughness effects in cavitating flow. Int J Heat Fluid Flow, 2011, 32: 1068–1075

Li L, Diver C, Atkinson J, et al. Sequential laser and EDM microdrilling for next generation fuel injection nozzle manufacture. CIRP Ann, 2006, 55: 179–182

Macian V, Bermudez V, Payri R, et al. New technique for determination of internal geometry of a diesel nozzle with the use of silicone methodology. Exp Techniques, 2003, 27: 39–43

Wu Z, Li Z, Huang W, et al. Comparisons of nozzle orifice processing methods using synchrotron X-ray micro-tomography. J Zhejiang Univ Sci A, 2012, 13: 182–188

Duke D J, Finney C E A, Kastengren A, et al. High-resolution X-ray and neutron computed tomography of an engine combustion network spray g gasoline injector. SAEInt J Fuels Lubr, 2017, 10: 2017–01–0824

Peiner E, Balke M, Doering L. Form measurement inside fuel injector nozzle spray holes. MicroElectron Eng, 2009, 86: 984–986

Tan H, Wang D, Li R, et al. A robust method for high-precision quantification of the complex three-dimensional vasculatures acquired by X-ray microtomography. J Synchrotron Rad, 2016, 23: 1216–1226

Li Z, Wu Z, Gao Y, et al. development and application of an automatic measurement method for nozzle orifice diameter and length. J Zhejiang Univ Sci A, 2015, 16: 11–17

Li Z L, Wu Z J, Gao Y, et al. New method for measuring diesel nozzle orif ice inlet structures based on synchrotron X-ray tomography. Chin Opt Lett, 2014, 12: 081201

Geometrical Product Specifications (GPS)—Surface Texture: Areal— Part 2: Terms, Definitions and Surface Texture Parameters. ISO 25178–2, 2012

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Z., Zhao, W., Wu, Z. et al. The measurement of internal surface characteristics of fuel nozzle orifices using the synchrotron X-ray micro CT technology. Sci. China Technol. Sci. 61, 1621–1627 (2018). https://doi.org/10.1007/s11431-018-9289-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9289-1