Abstract

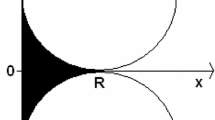

A model of three-dimensional helm-shaped body composed of a helm-shaped fin and inner heat sources is built in this paper. For the specified volumes of the body, fin and heat source, the constructal optimizations of the body with single and multiple inner heat sources are implemented. The entransy-dissipation-rate-based equivalent thermal resistance (ETR) is minimized in the optimizations. It shows that for the helm-shaped body with multiple inner heat sources, there exist an optimal ratio of the heat source distance to the radius of the extended fin and a twice optimal radius ratio of the centre fin to the extended fin which lead to the double minimum dimensionless ETR. Comparing the optimal result of the body with helm-shaped fin with that with annular fin, the radius of the centre fin and the distance between the heat source and the center of the body are decreased, and the ETR is decreased by 9.57%. Essentially, the temperature gradient field of the helm-shaped body is more homogenous, and its global heat transfer performance is improved.

Similar content being viewed by others

References

Bejan A. Shape and Structure, from Engineering to Nature. Cambridge: Cambridge University Press, 2000

Wang A, Liang X, Ren J. Constructal enhancement of heat conduction with phase change. Int J Thermophysics, 2006, 27: 126–138

Bejan A, Lorente S. Design with Constructal Theory. New Jersey: Wiley, 2008

Chen L G. Progress in study on constructal theory and its application. Sci China Tech Sci, 2012, 55: 802–820

Bejan A, Lorente S. Constructal law of design and evolution: Physics, biology, technology, and society. J Appl Phys, 2013, 113: 151301

Hajmohammadi M R, Rahmani M, Campo A, et al. Optimal design of unequal heat flux elements for optimized heat transfer inside a rectangular duct. Energy, 2014, 68: 609–616

Yang J, Fan A W, Liu W, et al. Optimization of shell-and-tube heat exchangers conforming to TEMA standards with designs motivated by constructal theory. Energy Convers Mgmt, 2014, 78: 468–476

Yang J, Oh S R, Liu W. Optimization of shell-and-tube heat exchangers using a general design approach motivated by constructal theory. Int J Heat Mass Transfer, 2014, 77: 1144–1154

Xie G, Zhang F, Sundén B, et al. Constructal design and thermal analysis of microchannel heat sinks with multistage bifurcations in single-phase liquid flow. Appl Thermal Engng, 2014, 62: 791–802

Xie G, Asadi M, Sunden B, et al Constructal theory based geometric optimization of wavy channels in the low Reynolds number regime. Trans ASME J Electronic Pack, 2014, 136: 031013

Bejan A, Dan N. Constructal trees of convective fins. Trans ASME J Heat Transfer, 1999, 121: 675–682

Bejan A, Almogbel M. Constructal T-shaped fins. Int J Heat Mass Transfer, 2000, 43: 2101–2115

Lorenzini G, Rocha L A O. Constructal design of Y-shaped assembly of fins. Int J Heat Mass Transfer, 2006, 49: 4552–4557

Xie Z H, Chen L G, Sun F R. Constructal optimization of twice level Y-shaped assemblies of fins by taking maximum thermal resistance minimization as objective. Sci China Tech Sci, 2010, 53: 2756–2764

Bello-Ochende T, Meyer J P, Bejan A. Constructal multi-scale pin-fins. Int J Heat Mass Transfer, 2010, 53: 2773–2779

Zhang X, Liu D. Optimum geometric arrangement of vertical rectangular fin arrays in natural convection. Energy Convers Mgmt, 2010, 51: 2449–2456

Lorenzini G, Corrêa R L. Constructal design of complex assembly of fins. Trans ASME J Heat Transfer, 2011, 133: 081902

Hajmohammadi M R, Poozesh S, Hosseini R. Radiation effect on constructal design analysis of a T-Y-shaped assembly of fins. J Thermal Sci Tech, 2012, 7: 677–692

Lorenzini G, Moretti S. Bejan’s constructal theory and overall performance assessment. The global optimization for heat exchanging finned modules. Thermal Sci, 2014, 18: 339–348

Song Y, Asadi M, Xie G, et al. Constructal wavy-fin channels of a compact heat exchanger with heat transfer rate maximization and pressure losses minimization. Appl Thermal Engng, 2015, 75: 24–32

Aziz A, Bouaziz M N. A least squares method for a longitudinal fin with temperature dependent internal heat generation and thermal conductivity. Energy Convers Mgmt, 2011, 52: 2876–2882

Aziz A, Torabi M, Zhang K. Convective-radiative radial fins with convective base heating and convective-radiative tip cooling: Homogeneous and functionally graded materials. Energy Convers Mgmt, 2013, 74: 366–376

Hajmohammadi M R, Poozesh S, Nourazar S S. Constructal design of multiple heat sources in a square-shaped fin. Proc I Mech E, J Process Mech Engng, 2012, 226: 324–336

Hajmohammadi M R, Poozesh S, Nourazar S S, et al. Optimal architecture of heat generating pieces in a fin. J Mech Sci Tech, 2013, 27: 1143–1149

Lorenzini G, Biserni C, Correa R L, et al. Constructal design of T-shaped assemblies of fins cooling a cylindrical solid body. Int J Thermal Sci, 2014, 83: 96–103

Kundu B, Lee K S. Analytical tools for calculating the maximum heat transfer of annular stepped fins with internal heat generation and radiation effects. Energy, 2014, 76: 733–748

Guo Z, Zhu H, Liang X. Entransy—A physical quantity describing heat transfer ability. Int J Heat Mass Transfer, 2007, 50: 2545–2556

Li Z, Guo Z. Field Synergy Principle of Heat Convection Optimization. Beijing: Science Press, 2010

Chen L G. Progress in entransy theory and its applications. Chin Sci Bull, 2012, 57: 4404–4426

Chen Q, Liang X, Guo Z. Entransy theory for the optimization of heat transfer-A review and update. Int J Heat Mass Transfer, 2013, 63: 65–81

Cheng X, Liang X. Entransy, entransy dissipation and entransy loss for analyses of heat transfer and heat-work conversion processes. J Thermal Sci Tech, 2013, 8: 337–352

Chen L G. Progress in optimization of mass transfer processes based on mass entransy dissipation extremum principle. Sci China Tech Sci, 2014, 57: 2305–2327

Cheng X, Liang X. Entransy: Its physical basis, applications and limitations. Chin Sci Bull, 2014, 59: 5309–5323

Chen L G, Wei S H, Sun F R. Constructal entransy dissipation minimization for “volume-point” heat conduction. J Phys D Appl Phys, 2008, 41: 195506

Chen L G, Wei S H, Sun F R. Constructal entransy dissipation rate minimization of a disc. Int J Heat Mass Transfer, 2011, 54: 210–216

Xie Z H, Chen L G, Sun F R. Comparative study on constructal optimizations of T-shaped fin based on entransy dissipation rate minimization and maximum thermal resistance minimization. Sci China Tech Sci, 2011, 41: 962–970

Xiao Q H, Chen L G, Sun F R. Constructal entransy dissipation rate minimization for umbrella-shaped assembly of cylindrical fins. Sci China Tech Sci, 2011, 54: 211–219

Feng H J, Chen L G, Sun F R. Constructal entransy dissipation rate minimization for leaf-like fins. Sci China Tech Sci, 2012, 55: 515–526

Chen L G, Xiao Q H, Xie Z H, et al. T-shaped assembly of fins with constructal entransy dissipation rate minimization. Int Comm Heat Mass Transfer, 2012, 39: 1556–1562

Chen L G, Xiao Q H, Xie Z H, et al. Constructal entransy dissipation rate minimization for tree-shaped assembly of fins. Int J Heat Mass Transfer, 2013, 67: 506–513

Cheng X, Zhang Q, Xu X, et al. Optimization of fin geometry in heat convection with entransy theory. Chin Phys B, 2013, 22: 020503

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy optimizations for insulation layer of steel rolling reheating furnace wall with convective and radiative boundary conditions. Chin Sci Bull, 2014, 59: 2470–2477

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization for variable cross-section insulation layer of the steel rolling reheating furnace wall. Int Comm Heat Mass Transfer, 2014, 52: 26–32

Jia H, Liu Z, Liu W, et al. Convective heat transfer optimization based on minimum entransy dissipation in the circular tube. Int J Heat Mass Transfer, 2014, 73: 124–129

Tao Y, He Y, Liu Y, et al. Performance optimization of two-stage latent heat storage unit based on entransy theory. Int J Heat Mass Transfer, 2014, 77: 695–703

Wang S, Xie X, Jiang Y. Optimization design of the large temperature lift/drop multi-stage vertical absorption temperature transformer based on entransy dissipation method. Energy, 2014, 68: 712–721

Cheng X, Liang X. A comparison between the entropy generation in terms of thermal conductance and generalized thermal resistance in heat exchanger analyses. Int J Heat Mass Transfer, 2014, 76: 263–267

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization for triangular heat trees at micro and nanoscales. Int J Heat Mass Transfer, 2015, 84: 848–855

Feng H J, Chen L G, Xie Z H, et al. Constructal optimization of complex fin with convective heat transfer based on entransy dissipation rate minimization (in Chinese). Acta Phys Sin, 2015, 64: 034701

Chen Q, Fu R, Xu Y. Electrical circuit analogy for heat transfer analysis and optimization in heat exchanger networks. Appl Energy, 2015, 139: 81–92

Chen Q, Wang Y, Xu Y. A thermal resistance-based method for the optimal design of central variable water/air volume chiller systems. Appl Energy, 2015, 139: 119–130

Cheng X, Liang X. Entransy variation associated with work. Int J Heat Mass Transfer, 2015, 81: 167–170

Qian X, Li Z, Li Z. Entransy and exergy analyses of airflow organization in data centers. Int J Heat Mass Transfer, 2015, 81: 252–259

COMSOL Multiphysics, version 4.2, Users’ Manuals, 2011

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, H., Chen, L., Xie, Z. et al. Constructal entransy dissipation rate minimization for helm-shaped fin with inner heat sources. Sci. China Technol. Sci. 58, 1084–1090 (2015). https://doi.org/10.1007/s11431-015-5833-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-015-5833-0