Abstract

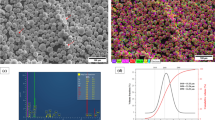

In this study, austenitizing heat treatment before hot stamping of Al-10% Si coated boron steel is first investigated through environment scanning electron microscopy (ESEM) equipped with energy dispersive x-ray analysis (EDAX). The cracking behavior of the coating was evaluated using Gleeble 3500, a thermo-mechanical simulator under uniaxial plastic deformation at elevated temperatures. The extent and number of cracks developed in the coating were carefully assessed through an optical microscope. The coating layer under hot-dipped condition consists of an Al-Si eutectic matrix, Fe2Al7Si, Fe3Al2Si3 and Fe2Al5, from the coating surface to the steel substrate. The coating layer remains dense, continuous and smooth. During austenitization, the Al-rich Fe-Al intermetallics in the coating transform to more Fe-rich intermetallics, promoted by the Fe diffusion process. The coating finally shows the coexistence of two types of Fe-Al intermetallics, namely, FeAl2 and FeAl. Microcracks and Kirkendall voids occur in the coating layer and diffusion zone, respectively. The coating is heavily cracked and broken into segments during the hot tensile tests. Bare steel exposed between the separate segments of the coating is oxidized and covered with a thin FeO x layer. The appearance of the oxide decreases the adhesion of the Al-Si coating. It is found that the ductile FeAl is preferred as a coating microstructure instead of the brittle FeAl2. Therefore, the ductility of the Al-Si coating on hot stamping boron steel could be enhanced by controlling the ductile Fe-rich intermetallic phase transformations within it during austenitization. Experiments indicate that a higher austenitizing temperature or longer dwell time facilitate the Fe-rich intermetallics transformation, increasing the volume fraction of FeAl. This phase transformation also contributes to reducing the crack density and depth.

Similar content being viewed by others

References

Gui Z X, Zhang Y S, Li H Q, et al. Hot stamping and blank designing for a vehicle bumper using ultra high strength steel (UHSS). Adv Mater Res, 2013, 690–693: 2240–2244

Wang C, Zhang Y S, Tian X W, et al. Thermal contact conductance estimation and experimental validation in hot stamping process. Sci China Tech Sci, 2012, 55: 1852–1857

Long A, Ge R, Zhang Y S, et al. Numerical simulation of b-pillar’s hot press forming process and its shape optimization. Appl Mech Mater, 2012, 138–189: 749–753

Jang J H, Lee J H, Joo B D, et al. Flow characteristics of aluminum coated boron steel in hot press forming. T Nonferr Metal Soc, 2009, 19: 913–916

Merklein M, Lechler J. Investigation of the thermo-mechanical properties of hot stamping steels. J Mater Process Tech, 2006, 177: 452–455

Merklein M, Lechler J, Geiger M. Characterization of the flow properties of the quenchenable ultra high strength steel 22MnB5. CRIP Ann-Manuf Technol, 2006, 55: 229–232

Mori K, Ito D. Prevention of oxidation in hot stamping of quenchable steel sheet by oxidation preventive oil. CRIP Ann-Manuf Tech, 2009; 58: 267–270

Kondratiku J, Kuhn P. Tribological investigation on friction and wear behaviour of coatings for hot sheet metal forming. Wear, 2011, 270: 839–849

Hu P, Ying L, Li Y, et al. Effect of oxide scale on temperature-dependent interfacial heat transfer in hot stamping process. J Mater Process Tech, 2013, 213: 1475–1483

Suehiro M, Kusumik K, Miyakoshi T, et al. Properties of aluminum-coated steels for hot stamping. Japan: Nippon Steel Technical Report, 2003

Jeon Y P, H. Seo Y, Kim J D, et al. Experimental analysis of coating layer behavior of Al-Si-coated boron steel in a hot bending process for IT applications. Int J Adv Manuf Tech, 2013, 67: 1693–1700

Azushima A, Uda K, Yanagida A. Friction behavior of aluminum-coated 22MnB5 in hot stamping under dry and lubricated conditions. J Mater Process Technol, 2012, 212: 1014–1021

Takahashi M. Development of High Strength Steels for Automobiles. Japan: Nippon Steel Technical Report, 2003

Chen Z T, Li G, Wu Z Q, et al. The crack propagating behavior of composite coatings prepared by PEO on aluminized steel during in situ tensile processing. Mater Sci Eng A, 2011, 528: 1409–1414

Wu C W, Huang C G, Chen G N. Interface delamination of the thermal barrier coating subjected to local heating. Sci China Tech Sci, 2010, 53: 3168–3174

Lara A, Picas I, Casellas D. Effect of cutting process on the fatigue behavior of press hardened and high strength dual phase steels. J Mater Process Tech, 2013, 213: 1908–1919

Gupta S P. Intermetallic compound formation in Fe-Al-Si ternary system: Part I. Mater Charact, 2003, 49: 269–291

Maitra T, Gupta S P. Intermetallic compound formation in Fe-Al-Si ternary system: Part II. Mater Charact, 2003, 49: 293–311

Cheng W J, Wang C J. Observation of high-temperature phase transformation in the Si-modified aluminide coating on mild steel using EBSD. Mater Charact, 2010, 6: 467–473

Windmann M, Rottger A, Theisen W. Phase formation at the interface between a boron alloyed steel substrate and an Al-rich coating. Surf Coat Tech, 2013, 226: 130–139

Cheng W J, Wang C J. Microstructural evolution of intermetallic layer in hot-dipped aluminide mild steel with silicon addition. Surf Coat Tech, 2011, 205: 4726–4731

Raghavan V. Al-Fe-Si (aluminum-iron-silicon). J Phase Equilib Diff, 2002, 23: 362–366

Kobayashi S, Yakou T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater Sci Eng A, 2002, 338: 44–53

Chang Y Y, Tsaur C C, Rock J C. Microstructure studies of an aluminide coating on 9Cr-1Mo steel during high temperature oxidation. Surf Coat Tech, 2006, 200: 6588–6593

Beuth J L, Klingbeil N W. Cracking of thin films bonded to elastic-plastic substrates. J Mech Phys Solids, 1996, 44: 1411–1428

Ye T, Suo Z, Evans A G. Thin film cracking and the roles of substrate and interface. Int J Solids Structures, 1992, 29: 2639–2648

Hu M S, Evans A G. The cracking and decohesion of thin films on ductile substrate. Acta Metall, 1989, 37: 917–925

George M, Coupeau C, Colin J, et al. Atomic force microscopy observations of successive damaging mechanisms of thin films on substrates under tensile stress. Thin Solid Films, 2003, 429: 267–272

Kattner U R, Massalski T B. Binary Alloy Phase Diagrams, in: H. Baker (Ed.), ASM International, Material Park, OH, 1990

Koster U, Liu W, Liebertz H, et al. Mechanical properties of quasicrystalline and crystalline phases in Al-Cu-Fe alloys. J Non Cryst Solids, 1993, 153-154: 446–452

Kubosova A, Karlik M, Hausild P, et al. Fracture behaviour of Fe3Al and FeAl type iron aluminides. Mater Sci Forum, 2008, 567-568: 349–352

Zhang D T. Effect of ductile-brittle transition temperature of Al-Si coating on fatigue properties of Ni-base superalloys. Acta Metall Sin, 1990, 26: 215–219

Naderia M, Saeed-Akbari A, Bleck W. The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel. Mater Sci Eng A, 2008, 487: 445–455

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gui, Z., Liang, W. & Zhang, Y. Enhancing ductility of the Al-Si coating on hot stamping steel by controlling the Fe-Al phase transformation during austenitization. Sci. China Technol. Sci. 57, 1785–1793 (2014). https://doi.org/10.1007/s11431-014-5576-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5576-3