Abstract

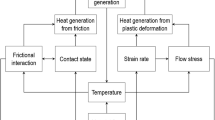

A multi-physics hybrid numerical model, which couples electric, magnetic, thermal and flow fields, was used to investigate electromagnetic stirring behavior in a resistance spot weld nugget. The differences of two kinds of different excitation inputs, i.e., a sinusoidal current and its root-mean-square (RMS) value, were studied to examine if they could produce equivalent electromagnetic stirring effects in the weld nugget. Research showed that the two types of current inputs could produce almost identical fluid flow and heat transfer patterns and consistent evolution of flow and thermal fields in the nugget. At the end of the welding cycles, the maximum flow velocity and temperature between the two inputs differed by 11.6% and 0.3%, respectively. Therefore, the RMS current can be assumed to produce an approximately equivalent electromagnetic stirring effect with the sinusoidal current, and can be used in the future research to greatly improve the solution efficiency of the electromagnetic stirring behavior in the resistance spot weld nugget.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Cunningham A, Begeman M L. A fundamental study of project welding using high speed photography computer. Weld J, 1965, 44: 381–384

Yang L F, Zhao X H, Cao H P. Critical technology study and progress of resistance spot-welding process numerical simulation (in Chinese). Aerospace Manuf Tech, 2004, 2: 50–54

Alcini W V. Experimental measurement of liquid nugget heat convection in spot welding. Weld Res Suppl, 1990, 69: 177–180

Wei P S, Wang S C, Lin M S. Transport phenomena during resistance spot welding. Trans ASME-J Heat Transf, 1996, 118: 762–773

Khan J A, Xu L J, Chao Y J, et al. Numerical simulation of resistance spot weld process. Numer Heat Tr Part A-Appl, 2000, 37: 425–446

Yang L F, Zhao X H, Cao H P. Finite element analysis of thermal field and flow field in spot welding for aluminum alloys (in Chinese). Trans China Weld Inst, 2004, 26(6): 4–6

Li Y B, Lin Z Q, Hu S J, et al. Numerical analysis of magnetic fluid dynamics behaviors during resistance spot welding. J Appl Phys, 2007, 101: 053506

Li Y B, Lin Z Q, Hu S J, et al. Magnetohydrodynamic behaviors in a resistance spot weld nugget under different welding currents. Sci China Ser E-Tech Sci, 2008, 51(9): 1507–1515

Nied H A. The finite element modeling of the resistance spot welding process. Weld J, 1984, 63: 123–132

Long X, Sanjeev K. Numerical simulation of residual stresses in a spot welded joint. Trans ASME-J Eng Mater Tech, 2003, 125: 222–226

Tsai C L, Dai W L, Dicknson D W, et al. Analysis and development of a real-time control methodology in resistance spot welding. Welding J, 1991, 100: 158–176

Li Y B, Lin Z Q, Lai X M, et al. Analysis of nugget formation process of resistance spot welding based on magnetic fluid dynamics theory (in Chinese). Trans China Weld Inst, 2006, 27: 41–45

Wang Q, Li G D. Basic Theory of Electromagnetic (in Chinese). Beijing: China Science Press, 1998

Jia R G, Xue Q Z. Electromagnetics (in Chinese). Beijing: Higher Education Press, 2003

Li Y B, Lin Z Q, Chen G L, et al. Study on moving GTA weld pool in an externally applied longitudinal magnetic field with experimental and finite element methods. Model Simul Mater Sci Eng, 2002, 10(6): 781–798

Valod N, Wilhelm Sc, Andrey V K. Internal flow and shell solidification in horizontal continuous casting processes. In: Proceedings of 8th International Conference on Modeling of Casting, Welding, and Advanced Solidification Processes-VIII, 1998 June 7–12, San Diego, CA, USA. 655–662

ANSYS. Version 12. Canonsburg: ANSYS Inc. 2001

Li W, Daniel C, Gerald A G. A comparative study of single-phase ac and multiphase DC resistance spot welding. Trans ASME-J Manuf Sci Eng, 2005, 127: 583–589

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Lin, Z., Lai, X. et al. Induced electromagnetic stirring behavior in a resistance spot weld nugget. Sci. China Technol. Sci. 53, 1271–1277 (2010). https://doi.org/10.1007/s11431-010-0086-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-0086-4