Abstract

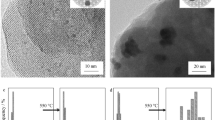

The stability of nanosized catalysts at high temperature is still a challenging topic and is a crucial criterion to evaluate their suitability for industrial use. Currently, the strategy to improve the high-temperature stability of nano-sized catalysts is to restrict the migration of particles on the surface, which, however, lacks theoretical knowledge and directions. Herein, we reported a new approach that can effectively inhibit the migration and agglomeration of supported nanoparticles by fabrication of a model catalyst Pt/CeO2/NiAl2O4/Al2O3@SiO2. This catalyst is highly stable with the microstructure unchanged even after being aged at 1000 °C. Density functional theory calculations indicate that two types of confinement effects exist in the catalyst and their mechanisms were well explained from the viewpoint of “energy traps” which can also be applied to other supported catalysts.

Similar content being viewed by others

References

Bell AT. Science, 2003, 299: 1688–1691

Valden, Lai, Goodman. Science, 1998, 281: 1647–1650

Merkle R, Maier J. Z Anorg Allg Chem, 2005, 631: 1163–1166

Levitas VI, Samani K. Nat Commun, 2011, 2: 284

Hansen TW, Delariva AT, Challa SR, Datye AK. Acc Chem Res, 2013, 46: 1720–1730

Yan W, Mahurin SM, Pan Z, Overbury SH, Dai S. J Am Chem Soc, 2005, 127: 10480–10481

Zhou HP, Wu HS, Shen J, Yin AX, Sun LD, Yan CH. J Am Chem Soc, 2010, 132: 4998–4999

Zhan W, He Q, Liu X, Guo Y, Wang Y, Wang L, Guo Y, Borisevich AY, Zhang J, Lu G, Dai S. J Am Chem Soc, 2016, 138: 16130–16139

Tang H, Liu F, Wei J, Qiao B, Zhao K, Su Y, Jin C, Li L, Liu JJ, Wang J, Zhang T. Angew Chem Int Ed, 2016, 55: 10606–10611

Cao A, Veser G. Nat Mater, 2010, 9: 75–81

Liu H, Zhang L, Wang N, Su DS. Angew Chem Int Ed, 2014, 54: 12634–12638

Lee I, Joo JB, Yin Y, Zaera F. Angew Chem, 2011, 123: 10390–10393

Cargnello M, Delgado Jaén JJ, Hernández Garrido JC, Bakhmutsky K, Montini T, Calvino Gámez JJ, Gorte RJ, Fornasiero P. Science, 2012, 337: 713–717

Joo SH, Park JY, Tsung CK, Yamada Y, Yang P, Somorjai GA. Nat Mater, 2009, 8: 126–131

Guo X, Fang G, Li G, Ma H, Fan H, Yu L, Ma C, Wu X, Deng D, Wei M, Tan D, Si R, Zhang S, Li J, Sun L, Tang Z, Pan X, Bao X. Science, 2014, 344: 616–619

Onn TM, Monai M, Dai S, Fonda E, Montini T, Pan X, Graham GW, Fornasiero P, Gorte RJ. J Am Chem Soc, 2018, 140: 4841–4848

Zhang D, Niu F, Li H, Shi L, Fang J. Powder Tech, 2011, 207: 35–41

Wang Z, Wang Q, Liao YC, Shen GL, Liu HD, Chen YF. J Nanopart Res, 2011, 13: 4969–4978

Liu Y, Wang S, Sun T, Gao D, Zhang C, Wang S. Appl Catal B-Environ, 2012, 119: 321–328

Pan X, Zhang Y, Zhang B, Miao Z, Wu T, Yang X. Chem Res Chin Univ, 2013, 29: 952–955

Zhao K, Qiao B, Wang J, Zhang Y, Zhang T. Chem Commun, 2011, 47: 1779–1781

Matsubu JC, Zhang S, DeRita L, Marinkovic NS, Chen JG, Graham GW, Pan X, Christopher P. Nat Chem, 2017, 9: 120–127

Jones J, Xiong H, DeLaRiva AT, Peterson EJ, Pham H, Challa SR, Qi G, Oh S, Wiebenga MH, Pereira Hernández XI, Wang Y, Datye AK. Science, 2016, 353: 150–154

Wu T, Pan X, Zhang Y, Miao Z, Zhang B, Li J, Yang X. J Phys Chem Lett, 2014, 5: 2479–2483

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2016YFC0204301), the National Natural Science Foundation of China (21872133, 21273221) and Youth Innovation Promotion Association of Chinese Academy of Sciences (2018263).

Author information

Authors and Affiliations

Corresponding authors

Supporting Information online

Rights and permissions

About this article

Cite this article

Li, J., Li, K., Sun, L. et al. Sinter-resistant and high-efficient Pt/CeO2/NiAl2O4/Al2O3@SiO2 model catalysts with “composite energy traps”. Sci. China Chem. 63, 519–525 (2020). https://doi.org/10.1007/s11426-019-9678-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-019-9678-5