Abstract

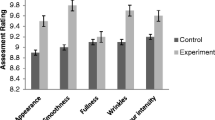

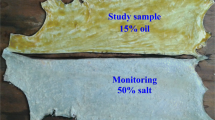

A method of dehairing of goat skins using oxidative chemicals and protease enzymes has been attempted. The dehairing process is one of the important and essential steps in leather making, where hair is removed by lime and sodium sulphide in the conventional process. This conventional dehairing system generates a higher amount of pollution problem as compared to the other unit operations and unit processes. In this work, dehairing of the goat skins through oxidative agents namely magnesium peroxide and protease enzyme has been attempted. For this, protease has been produced from Bacillus sp. at the laboratory level and the activity was found. The dehairing of goat skins takes place for the duration of 14–16 h. The leather produced with the experimental sample showed comparable organoleptic and strength properties with the conventional sample. This method paved the way for the reduction of pollution loads especially BOD, COD, and TDS to the level of 59, 27, and 77%, respectively, in comparison with the control sample. The reaction kinetics for the formation of the ligand-macromolecular complex is found in the isothermal titration calorimetry (ITC) experiment and a mathematical model has been formulated. The dyed crust leather showed comparable colour properties. In addition to that, there is a reduction in processing time for leather making through skipping reliming and deliming processes which are said to be another advantage of this method. The physical strength properties of the experimental leather were also comparable with conventionally produced leather.

Similar content being viewed by others

Data availability

All the authors have given all the data and materials for publishing the manuscript in this journal. If any supplementary material is required, all the authors abide to journal to provide the same.

References

Abraham J, Gea T, Sanchez A (2014) Substitution of chemical dehairing by proteases from solid-state fermentation of hair wastes. J Clean Prod 74:191–198

Adriano B (2008) Bacterial Keratinases: Useful enzymes for bioprocessing agroindustrial wastes and beyond. Food Bioprocess Technol 1:105–116

Akram F, Haq IU, Hayat AK, Ahmed Z, Jabbar Z, Baig IM, Akram R (2021) Keratinolytic enzyme from a thermotolerant isolate Bacillus sp. NDS-10: an efficient green biocatalyst for poultry waste management, laundry and hide-dehairing applications. Waste Biomass Valor 12:5001–5018

Amir S, Benlboukht F, Cancian N, Winterton P, Hafidi M (2008) Physico-chemical analysis of tannery solid waste and structural characterization of its isolated humic acids after composting. J Haz Mat 160:448–445

Andrioli E, Gutteres M (2014) Associated use of enzymes and hydrogen peroxide for cowhide hair removal. J Am Leat Chem Assoc 109(2):35–69

Annapurna Raju A, Chandrababu NK, Samivelu N, Rose C, Muralidhara Rao N (1996) Eco-friendly enzymatic dehairing using extra-cellular proteases from a Bacillus species isolate. J Am Leath Chem Ass 91:115–118

Arunachalam C, Saritha K (2009) Protease enzyme an eco-friendly alternative for leather industry. Ind J Sci Technol 2(12):29–32

Brown A (2009) Analysis of cooperativity by isothermal titration calorimetry. Int J Mol Sci 10:3457–3477

Cantera CS, Garro ML, Goya L, Babeito C, Galarza B (2004) Hair saving unhairing process. Part 6. Stratum corneum as a diffusion barrier: chemical- mechanical injury of epidermis. J Soc Leather Technol Chem 88:121–130

Dayanadan A, Kanagaraj J, Sunderraj L, Govindaraju R, Suseela RG (2003) Application of alkaline protease in leather processing - an eco-friendly approach. J Clean Prod 11:533–536

Detimer A, Patricia SDA, Maritiz G (2013) Special review paper: enzymes in the leather industry. J Am Leat Chem Assoc 10:146–155

Dixit S, Yadav A, Dwivedi PD, Das M (2014) Toxic hazards of leather industry and technologies to combat threat: a review. J Clean Prod 87(1):39–49

Durga J, Ranjithkumar A, Ramesh R, Girivasan KT, Rose C, Muralidharan C (2016) Replacement of lime with carbohydrases – a successful cleaner process for leather making. J Clean Prod 112(1):1122–1127

Eaton AD, Clesceri, LS, Greenberg AE (1995) Standard methods of the examination of water and waste water. The American Public Health Association (APHA), Washington

Gehring AG, Bailey DG, Dimaio GL (2003) Rapid oxidative unhairing with alkaline calcium peroxide. J Am Leat Chem Assoc 98(6):216–223

George N, Chauhan PS, Kumar V, Puri N, Gupta N (2014) Approach to eco-friendly leather: charactersistics and application of an alkaline protease for chemical free dehairing of skins and hides at pilot scale. J Clean Prod 7:249–257

Guo ZR, Zhang G, Fang J, Dou X (2006) Enhanced chromium recovery from tanning waste water. J Clean Prod 14:75–79

Hones P, Diserens M, Levy F (1999) Characterization of sputter-deposited chromium oxide thin films. Surf Coat Technol 120–121:277–283

Hu J, Xiao Z, Zhou R, Deng W, Wang M, Ma S (2010) Ecological utilization of leather tannery waste with circular economy model. J Clean Prod 18:221–228

IUP 16 (2015) ISO 3380: 2015. Leather - physical and mechanical tests - determination of shrinkage temperature up to 100 °C

Jegannathan KR, Nielsen PH (2013) Environmental assessment of enzyme use in industrial production– a literature review. J Clean Prod 42:228–240

Kamini NR, Hemachander C, Mala SM, Puvanakrishnan R (1999) Microbial enzyme technology as an alternative to conventional chemicals in leather industry. Current Scie 77:80–86

Kanagaraj J, Mandal AB (2012) Combined biodegradation and ozonation for removal of tannins and dyes for the reduction of pollution loads. Environ Scie Poll Res 19:42–52

Kanagaraj J, Panda RC (2011) Modelling of dye uptake rate, related interactions, and binding energy estimation in leather matrix using protein based nanoparticle polymer. Ind Eng Chem Res 50(22):12400–12408

Kanagaraj J, Chandra Babu NK, Mandal AB (2008) Recovery and reuse of chromium from chrome tanning waste water aiming towards zero discharge of pollution. J Clean Prod 16:1807

Kanagaraj J, Panda RC, Sumathi V (2015a) Water soluble graft copolymer synthesized from collagenous waste and PEG with functional carboxylic chains: A highly efficient adsorbent for chromium (III) with continuous recycling and molecular docking studies. Ind Eng Chem Res 54:7401–7414

Kanagaraj J, Senthilvelan T, Panda RC, Kavitha S (2015b) Eco-friendly waste management strategies for greener environment towards sustainable development in leather industry: a comprehensive review. J Clean Prod 89:1–17

Kanagaraj J, Senthilvelan T, Panda RC (2016a) Remediation of sulfide based dehairing by oxidative dehairing of skin and correlation by mathematical model: an eco-friendly approach. Proc Safety Environ Protection 100:36–48

Kanagaraj J, Panda RC, Senthilvelan T, Gupta S (2016b) Cleaner approach in leather dyeing using graft copolymer adsorbent: related kinetics and mechanism. J Clean Prod 112:4863–4878

Kanagaraj J, Panda RC, Vinodh Kumar M (2020a) Trends and advancements in sustainable leather processing: future directions and challenges—a review. J Env Chem Eng 8:104379

Kanagaraj J, Panda RC, Jayakumar JC (2020b) Interaction of glyoxal with collagenous matrix and its behavioral aspects for non-toxic and sustainable tanning system. Int J Environ Scie Technol 17(2):879–890

Kanagaraj J, Panda RC, Prasanna R (2022) Sustainable chrome tanning system using protein based product developed from leather waste: wealth from waste. Polym Bull 79:10201–10228

Kandasamy N, Velmurugan P, Sundarvel A, Raghava RJ, Bangaru C, Palanisamy T (2012) Eco-benign enzymatic dehairing of goatskins utilizing a protease from a Pseudomonas fluorescens species isolated from fish visceral waste. J Clean Prod 25:27–33

Kanth SV, Venba R, Madhan B, Chandrababu NK, Sadulla S (2009) Cleaner tanning practices for tannery pollution abatement: role of enzymes in eco-friendly vegetable tanning. J Clean Prod 17(5):507–515

Kilic E, Puig R, Baquero G, Font J, Colak S, Gurler D (2011) Environmental optimization of chromium recovery from tannery sludge using a life cycle assessment approach. J Hazard Mat 192(1):393–401

Li K, Chen H, Wang Y, Shan Z, Yang J, Brutto PA (2009) Salt free pickling regime for hides and skins using oxazolidine. J Clean Prod 17(17):1603–1606

Linton DJ, Klassen R, Jayaraman V (2007) Sustainable supply chains: an introduction. J Oper Management 25:1075–1082

Ma J, Hou X, Gao D, Lv B, Zhang J (2014) Greener approach to efficient leather soaking process: role of enzymes and their synergistic effect. J Clean Prod 78:226–232

Malay S, Rajnish V (2017) Partial characterization of keratinase from Stenotrophomonas maltophilia K279a and study of its dehairing potential. Int J Biotechnol Biochem 13(1):95–110

Marmer WN, Dudley RL (2005) Oxidative dehairing by sodium percarborate. J Am Leat Chem Assoc 100:427–431

Marshal A, Cot J, Bartoli E (2002) Oxidising unhairing process with hair recovery. J Soc Leat Technol Chem 86:30–35

McKillop A, Sanderson WR (1995) Sodium perborate and sodium percarbonate: cheap, safe and versatile oxidizing agents for organic synthesis. Tetrahedron 55:6145–6166

Morera JM, Bartolí E, Chico R, Solé C, Cabeza LF (2011) Minimization of the environmental impact of chrome tanning: a new process reusing the tanning floats. J Clean Prod 19(17–18):2128–2132

Murugappan G, Zakir MJ, Jayakumar GC, Khambhaty Y, Sreeram KJ, Rao JR (2016) A novel approach to enzymatic unhairing and fiber opening of skin using enzymes immobilized on magnetite nanoparticles. ACS Sust Chem Engg 4(3):828–834

Muthsubramanian L, Mitra RB (2006) A cleaner production method for the synthesis of bronopol- a bactericide that is useful in leather making. J Clean Prod 14:536–538

Nashy EHA, Ismail SA, Ahmady AM, El-Fadaly H, El-Sayed NH (2005) Enzymatic bacterial dehairing of bovine hide by a locally isolated strain of Bacillus lichniformis. J Soc Leat Technol Chem 89:242–249

Neil MJ (ed) (2006) The Merck index - an encyclopedia of chemicals, drugs, and biologicals. Merck and Co., Inc., Whitehouse Station, NJ

Priya P, Archana G (2008) Hide depilation and feather disintegration studies with keratinolytic serine protease from a novel Bacillus subtilis isolate. Appl Microbiol Biotechnol 78:643–650

Qiang T, Xin G, Jing R, Xiaoke C, Xuechuan W (2016) A chrome-free and chrome-less tanning system based on the hyperbranched polymer. ACS Sust Chem Eng 4(3):701–707

Ramesh RR, Muralidharan V, Palanivel S (2018) Preparation and application of unhairing enzyme using solid wastes from the leather industry-an attempt toward internalization of solid wastes within the leather industry. Environ Sci Poll Res 25(3):2121–2136

Ranjithkumar A, Durga J, Ramesh R, Rose C (2017) Cleaner processing: a sulphide-free approach for depilation of skins. Env Scie Poll Res 24(1):1–9

Richardson Gavin D, Fantauzzo KA, Bazzi H, Maatta A, Jahoda CAB (2009) Dynamic expression of syndecan-1 during hair follicle morphogenesis. Gene Expr Patterns 9(6):454–460

Saran S, Mahajan RV, Kaushik R, Isar J, Saxena RK (2013) Enzyme mediated beam house operations of leather industry: a needed step towards greener technology. J Clean Prod 54(1):315–322

Saravanan P, Shiny Renitha T, Gowthaman MK, Kamini NR (2014) Understanding the chemical free enzyme based cleaner unhairing process in leather manufacturing. J Clean Prod 79(15):258–264

Sarkis J (2003) A strategic decision framework for green supply chain management. J Clean Prod 11:397–409

Saurabh S, Richi VM, Rekha K, Jasmine I, Rajendra KS (2013) Enzyme mediated beam house operations of leather industry: a needed step towards greener technology. J Clean Prod 54(1):315–322

Senthilvelan T, Kanagaraj J, Mandal AB (2012) Application of enzymes for dehairing of skins: cleaner leather processing. Clean Techn Environ Policy 14:889–897

Shi B, Lu X, Sun D (2003) The mechanism of oxidative unhairing using hydrogen peroxide. J Am Leat Chem Ass 98(5):185–192

Song S, Tao W, Chen W (2011) Kinetics of enzymatic unhairing by protease in leather industry. J Clean Prod 119(4):325–331

Subbarao CH, Sathish T, Ravichandra P, Prakasam RS (2009) Characterization of thermo and detergent stable serine protease from isolated bacillus circulans and evaluation of eco-friendly applications. Proc Biochem 44:262–268

Thangam EB, Rajkumar GS (2002) Purification and characterization of alkaline protease from Alcaligenes faecalis. Biotechnol Appl Biochem 35(2):149–154

Tian J, Xu Z, Long X, Tian Y, Shi B (2019) High-expression keratinase by Bacillus subtilis SCK6 for enzymatic dehairing of goatskins. Int J Biol Macromol 15(135):119–126

Uddin ME, Ahmad T, Ajam MM, Moniruzzaman M, Mandol D, Ray SK, Sufian A, Rahman MA, Hossain E, Ahammed T (2017) Thermotolerant extracellular proteases produced by bacillus subtilis isolated from local soil that representing industrial applications. J Pure Appl Microbiol 11(2):733–741

Valeika V, Beleska K, Valeikiene V, Kolodzeiskis V (2009) An approach to cleaner production: from hair burning to hair saving using a lime-free unhairing system. J Clean Prod 17(2):214–221

Verma A, Pal HS, Singh R, Agarwal S (2011) Pottential of alkaline protease isolated from thermoactinomyces sp. RM4 as an alternative to conventional chemicals in leather industry dehairing process. Int J Agril Env Biotech 4(2):173–178

Wang R, Min C, Haiming C, Li Z (2009) Enzyme unhairing an eco-friendly biotechnological process. J Soc Leat Technol Chem 93:51–55

Wei X, Lifen H, Lei Z (2010) Cleaner dehairing technology for goatskins: effects of hydrosulfide and peroxide on enzyme unhearing. Adv Mat Res 113–114:1726–1731

Yang Na, Ma J, Shi J, Yang X, Jun Lu (2022) Manipulate the nano-structure of layered double hydroxides via calcination for enhancing immobilization of anionic dyes on collagen fibers. J Coll Int Scie 610:182–193

Acknowledgements

All the authors would like to acknowledge and thank CSIR, New Delhi for approving the FBR project with code MLP-2004 for carrying out this work.

Funding

The authors thank Council of Scientific & Industrial Research (CSIR), New Delhi, India for sponsoring and permitting to carry out this work under Focused Basic Research (FBR) project with code: MLP 2004.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Dr. James Kanagaraj, Dr. Rames C. Panda, Ramakrishna Prasanna, and Alagamuthu Tamilselvi. The first draft of the manuscript was written by Dr. James Kanagaraj and all authors commented on previous versions of the manuscript. Dr. Alagamuthu Tamilselvi has contributed in analysis of results. All authors read and approved the final manuscript. All authors agree to publish and participate as per the norms of the journal.

Corresponding author

Ethics declarations

Ethical approval

All procedures performed in studies involving dehairing systems were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki Declaration and its later amendments or comparable ethical standards.

Consent to participate

All authors who have contributed to the study have agreed to participate as per the journal directions.

Consent for publication

All authors who have contributed to the study have agreed to publish as per the journal directions.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanagaraj, J., Panda, R.C., Prasanna, R. et al. An efficient dehairing system supported by oxidative-enzymatic auxiliary towards sustainability. Environ Sci Pollut Res 30, 43817–43832 (2023). https://doi.org/10.1007/s11356-023-25380-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-25380-3