Abstract

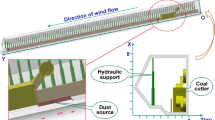

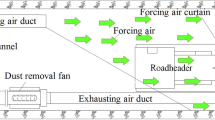

The development of coal industry is restricted by dust pollution. Air curtain dust control technology was proposed as a solution to the serious problem of pollution. A mixture of numerical modeling and field tests has been used to study this technology. Numerical simulation is used to analyze the dust control effect of this technology under different dust generation conditions. Field measurements are used to verify the effectiveness of this technology. The results show that following the application of this technology, the fan-shaped air curtain generated by the fans forms a trapezoidal protective area between the coal cutter and the sidewalk. This protective area prevents dust from entering the coal-cutter driver’s workspace. The average dust concentrations where the coal-cutter driver works were 1590 and 466 mg/m3, severally, before and after the implementation of this technology. The dust control rate in this space is approximately 70.69%. This research provides useful data for dust control technology in fully mechanized mining faces, and will contribute to the stable development of coal fuel.

Similar content being viewed by others

Availability of data and materials

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

References

Alobaid F (2015) An offset-method for Euler-Lagrange approach. Chem Eng Sci 138:173–193

Arya S, Sottile J, Novak T (2018) Development of a flooded-bed scrubber for removing coal dust at a longwall mining section. Saf Sci 110:204–213

Bao Q, Nie W, Liu C, Zhang H, Wang H, Jin H, Yan J, Liu Q (2020) The preparation of a novel hydrogel based on crosslinked polymers for suppressing coal dusts. J Clean Prod 249:119343

Cai P, Nie W, Liu Z, Xiu Z, Peng H, Du T, Yang B (2020) Study on the air curtain dust control technology with a dust purifying fan for fully mechanized mining face. Powder Technol 374:507–521

Cai X, Nie W, Yin S, Liu Q, Hua Y, Guo L, Cheng L, Ma Q (2021) An assessment of the dust suppression performance of a hybrid ventilation system during the tunnel excavation process: Numerical simulation. Process Saf Environ 152:304–317

Chang P, Xu G, Zhou F, Mullins B, Abishek S, Chalmers D (2019) Minimizing DPM pollution in an underground mine by optimizing auxiliary ventilation systems using CFD. Tunn Undergr Space Technol 87:112–121

Chen D, Nie W, Xiu Z, Yang B, Du T, Liu Q, Peng H (2022) Research on environmental dust pollution: ventilation and dust space–time evolution law of a fully mechanized mining face with 7-m mining height. Environ Sci Pollut R

Cheng W, Nie W, Yao Y, Zhou G, Yu Y, Yang J (2011) Numerical simulation on the flow field of swirling flow air curtain aspiration control dust in fully mechanized workface. J China Coal Soc 36(8):1342–1348

Goubran S, Qi D, Saleh WF, Wang L, Zmeureanu R (2016) Experimental study on the flow characteristics of air curtains at building entrances. Build Environ 105:225–235

Guo L, Nie W, Yin S, Liu Q, Hua Y, Cheng L, Cai X, Xiu Z, Du T (2020) The dust diffusion modeling and determination of optimal airflow rate for removing the dust generated during mine tunneling. Build Environ 178:106846

Hua Y, Nie W, Liu Q, Peng H, Wei W, Cai P (2020) The development and application of a novel multi-radial-vortex-based ventilation system for dust removal in a fully mechanized tunnelling face. Tunn Under Sp Tech 98:103253

Huang Q, Liu S, Cheng W, Wang G (2020) Fracture permeability damage and recovery behaviors with fracturing fluid treatment of coal: An experimental study. Fuel 282:118809

Kumar A, Schafrik S, Novak T (2020) Multi-phase computer modeling and laboratory study of dust capture by an inertial Vortecone scrubber. Int J Min Sci Techno 30:287–291

Li Y, Su H, Ji H, Cheng W (2020) Numerical simulation to determine the gas explosion risk in longwall goaf areas: A case study of Xutuan Colliery. Int J Min Sci Techno 30:875–882

Li K, Song X, Zhang C (2021a) Particle flow code analysis of geometrical and mechanical representative elementary volumes size of fractured rock mass. J Shandong Univ Sci Technol (Nat Sci) 40:59–68

Li R, Zhou G, Mo P, Hall M,Chen J, Chen D, Cai S (2021b) Behaviour of granular matter under gravity-induced stress gradient: a two-dimensional numerical investigation. Int J Min Sci Techno 31:439–450

Liu Q, Nie W, Hua Y, Peng H, Liu C, Wei C (2019) Research on tunnel ventilation systems: dust diffusion and pollution behaviour by air curtains based on CFD technology and field measurement. Build Environ 147:444–460

Liu Y, Xia T, Wang Y, Chen J, Li X (2020) Simulation and experimental investigation of dust-collecting performances of different dust exhaust hoods. J Air Waste Manag Assoc 70(12):1367–1377

Liu X, Nie W, Hua Y, Liu C, Guo L, Ma W (2021a) Behavior of diesel particulate matter transport from subsidiary transportation vehicle in mine. Environ Pollut 270:116264

Liu C, NieW, Liu X, Hua Y, Zhou W, Yu F, Niu W, Sun N, Xue Q (2021b) Behavior of the particulate matter (PM) emitted by trackless rubber-tyred vehicle (TRTV) at an idle speed under different movement conditions and ventilation optimization. Sci Total Environ 783:147008

Ma Q, Nie W, Yang S, Xu C, Peng H, Liu Z, Guo C, Cai X (2020) Effect of spraying on coal dust diffusion in a coal mine based on a numerical simulation. Environ Pollut 264:114717

Nie W, Guo C, Zhang S, Peng H, Xu C, Ma Q, Yuan M, Zhou W, Guo L, Cheng L (2021) Optimization of spraying dust reduction technology of continuous miner machine and the dust environment in a tunnel based on computational fluid dynamics (CFD) technology. Powder Technol 117044

Nie W, Sun N, Liu Q, Guo L, Xue Q, Liu C, Niu W (2022a) Comparative study of dust pollution and air quality of tunnelling anchor integrated machine working face with different ventilation. Tunn Under Sp Tech 122:104377

Nie W, Liu X, Liu C, Guo L, Hua Y (2022b) Prediction of dispersion behavior of typical exhaust pollutants from hydraulic support transporters based on numerical simulation. Environ Sci Pollut R

Niu W, Nie W, Yuan M, Bao Q, Zhou W, Yan J, Yu F, Liu C, Sun N, Xue Q (2021) Study of the microscopic mechanism of lauryl glucoside wetting coal dust: Environmental pollution prevention and control. J Hazard Mater 412:125223

Peng H, Nie W, Zhang S, Cheng W, Liu Q, Guo C, Ma Q, Zhou Z, Xu C, Hua Y, Zhang H (2022) Research on negative pressure jet dust-removal water curtain technology for coal mine cleaner production. Fuel 310:122378

Seaman C, Shahan M, Beck T, Mischler S (2020) Design of a water curtain to reduce accumulations of float coal dust in longwall returns. Int J Min Sci Techno 30:443–447

Sun B, Cheng W, Wang J, Wang H (2018) Effects of turbulent airflow from coal cutting on pollution characteristics of coal dust in fully-mechanized mining face: a case study. J Clean Prod 201:308–324

Sun L, Wang H, Zhang C, Zhang S, Liu N, He Z (2021) Evolution of methane ad-/desorption and diffusion in coal under in the presence of oxygen and nitrogen after heat treatment. J Nat Gas Sci Eng 95:104196

Wang P, Liu R, Tang M, Zhang W, Gui Z (2015) Experimental study on dust-isolating of rotating air curtain at fully mechanized work face. Chin J Environ Eng 9(8):3895–3901

Wang Q, Wang D, Wang H, Shen Y, Zhu X (2018) Experimental investigations of a new surfactant adding device used for mine dust control. Powder Technol 327:303–309

Wang P, Li Y, Liu R, Shi Y (2019a) Effects of forced-to-exhaust ratio of air volume on dust control of wall-attached swirling ventilation for mechanized excavation face. Tunn Undergr Space Technol 90:194–207

Wang Z, Li S, Ren T, Wu J, Lin H, Shuang H (2019b) Respirable dust pollution characteristics within an underground heading face driven with continuous miner - a CFD modelling approach. J Clean Prod 217:267–283

Wang Q, Wang D, Han F, Yang F, Sheng Y (2020) Study and application on foam-water mist integrated dust control technology in fully mechanized excavation face. Process Saf Environ Prot 133:41–50

Wang Z, Yin Y, Zhao T, Ma J, Wu W (2021) Numerical simulation study on bolting mechanism and support control of soft rock roadway. J Shandong Univ Sci Technol (Nat Sci) 40:35–43

Xiu Z, Nie W, Yan J, Chen D, Cai P, Liu Q, Du T, Yang B (2020) Numerical simulation study on dust pollution characteristics and optimal dust control air flow rates during coal mine production. J Clean Prod 248

Xu C, Nie W, Liu Z, Peng H, Yang S, Liu Q (2019) Multi-factor numerical simulation study on spray dust suppression device in coal mining process. Energy 182:544–558

Xue Q, Nie W, Guo L, Liu Q, Hua Y, Sun N, Liu C, Niu W (2022) Determining the optimal airflow rate to minimize air pollution in tunnels. Process Saf Environ 157:115–130

Yang S, Nie W, Lv S, Liu Z, Peng H, Ma X, Cai P, Xu C (2019) Effects of spraying pressure and installation angle of nozzles on atomization characteristics of external spraying system at a fully-mechanized mining face. Powder Technol 343:754–764

Zhang Q, Zhou G, Qian X, Yuan M, Sun Y, Wang D (2018) Diffuse pollution characteristics of respirable dust in fully-mechanized mining face under various velocities based on CFD investigation. J Clean Prod 184:239–250

Zhang K, Zhang J, Wei J, Ren T, Xu X (2019) Coal seam water infusion for dust control: a technical review. Environ Sci Pollut Res 26(5):4537–4554

Zhang X, Nie W, Peng H, Chen D, Du T, Yang B, Niu W (2021a) Onboard air curtain dust removal method for longwall mining: Environmental pollution prevention. J Environ Chem Eng 9:106387

Zhang L, Wang G, Yu J, Xiao Z, Wang K (2021b) Permeability evolution model and application of dual-porosity and dualpermeability coalbed. J Shandong Univ Sci Technol (Nat Sci) 40:33–42

Zhang H, Nie W, Liang Y, Chen J, Peng H (2021c) Development and performance detection of higher precision optical sensor for coal dust concentration measurement based on Mie scattering theory. Opt Laser Eng 144:106642

Zhou Q, Qin B, Wang F, Wang H, Hou J, Wang Z (2019) Effects of droplet formation patterns on the atomization characteristics of a dust removal spray in a coal cutter. Powder Technol 344:570–580

Funding

This work has been funded by the National Natural Science Foundation of China (NO. 51874191 and 51404147), the Focus on Research and Development Plan in Shandong Province (NO. 2017GSF20111), the National Key R&D Program of China (2017YFC0805201), and the China Post Doctoral Science Foundation (NO. 2015M570601 and 2017T100503).

Author information

Authors and Affiliations

Contributions

Wen Nie: supervision, project administration. Xu Zhang: conceptualization, methodology, software, numerical simulation. Huitian Peng: investigation, data curation. Dawei Chen: software, validation. Tao Du: assist in numerical simulation. Bo Yang: resources. Chengyi Liu: software.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nie, W., Zhang, X., Peng, H. et al. Research on air curtain dust control technology for environmental protection at fully mechanized working faces. Environ Sci Pollut Res 29, 43371–43384 (2022). https://doi.org/10.1007/s11356-022-18775-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-18775-1