Abstract

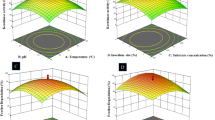

Bacillus sp. CL18 was investigated to propose a bioprocess for protease production using feathers as organic substrate. In feather broth (FB), containing feathers as sole organic substrate (1–100 g l−1), maximal protease production was observed at 30 g l−1 (FB30) after 6 days of cultivation, whereas increased feather concentrations negatively affected protease production and feather degradation. Protease production peaks were always observed earlier during cultivations than maximal feather degradation. In FB30, 80% of initial feathers mass were degraded after 7 days. Addition of glucose, sucrose, starch, yeast extract (2 g l−1), CaCl2, or MgCl2 (10 mmol l−1) to FB30 decreased protease production and feather degradation. FB30 supplementation with NH4Cl (1 g l−1) resulted in less apparent negative effects on protease production, whereas peptone (2 g l−1) increased protease yields earlier during cultivations (3 days). Through a central composite design employed to investigate the effects of peptone and NH4Cl (0.5–4.5 g l−1) on protease production and feather degradation, FB30 supplementation with peptone and NH4Cl (0.5–1.1 g l−1) increased protease production within a shorter cultivation time (5 days) and hastened complete feather degradation (6 days). Feather bioconversion concurs with sustainable production of value-added products.

Similar content being viewed by others

References

Bernal C, Vidal L, Valdivieso E, Coello N (2003) Keratinolytic activity of Kocuria rosea. World J Microbiol Biotechnol 19:255–261. doi:10.1023/A:1023685621215

Bernal C, Diaz I, Coello N (2006) Response surface methodology for the optimization of keratinase production in culture medium containing feathers produced by Kocuria rosea. Can J Microbiol 52:445–450. doi:10.1139/w05-139

Bhange K, Chaturvedi V, Bhatt R (2016) Feather degradation potential of Stenotrophomonas maltophilia KB13 and feather protein hydrolysate (FPH) mediated reduction of hexavalent chromium. 3 Biotech 6:42. doi:10.1007/s13205-016-0370-5

Bhargavi PL, Prakasham RS (2017) Agro-industrial wastes utilization for the generation of fibrinolytic metalloprotease by Serratia marcescens RSPB11. Biocatal Agric Biotechnol 9:201–208. doi:10.1016/j.bcab.2016.11.008

Bohacz J (2017) Biodegradation of feather waste keratin by a keratinolytic soil fungus of the genus Chrysosporium and statistical optimization of feather mass loss. World J Microbiol Biotechnol 33:13. doi:10.1007/s11274-016-2177-2

Bose A, Chawdhary V, Keharia H, Subramanian RB (2014a) Production and characterization of a solvent-tolerant protease from a novel marine isolate Bacillus tequilensis P15. Ann Microbiol 64:343–354. doi:10.1007/s13213-013-0669-y

Bose A, Pathan S, Pathak K, Keharia H (2014b) Keratinolytic protease production by Bacillus amyloliquefaciens 6B using feather meal as substrate and application of feather hydrolysate as organic nitrogen input for agricultural soil. Waste Biomass Valor 5:595–605. doi:10.1007/s12649-013-9272-5

Brandelli A, Daroit DJ, Riffel A (2010) Biochemical features of microbial keratinases and their production and applications. Appl Microbiol Biotechnol 85:1735–1750. doi:10.1007/s00253-009-2398-5

Burtt EH, Ichida JM (1999) Keratinase produced by Bacillus licheniformis US Patent number 5877000

Chaturvedi V, Bhange K, Bhatt R, Verma P (2014) Production of kertinases using chicken feathers as substrate by a novel multifunctional strain of Pseudomonas stutzeri and its dehairing application. Biocatal Agric Biotechnol 3:167–174. doi:10.1016/j.bcab.2013.08.005

Daroit DJ, Brandelli A (2014) A current assessment on the production of bacterial keratinases. Crit Rev Biotechnol 34:372–384. doi:10.3109/07388551.2013.794768

De Oliveira CT, Pellenz L, Pereira JQ, Brandelli A, Daroit DJ (2016) Screening of bacteria for protease production and feather degradation. Waste Biomass Valor 7:447–453. doi:10.1007/s12649-015-9464-2

De Oliveira CT, Pereira JQ, Brandelli A, Daroit DJ (2017) Prospecting soil bacteria from subtropical Brazil for hydrolases production. Biologia 72:130–139. doi:10.1515/biolog-2017-0025

Demir T, Hameş EE, Öncel SS, Vardar-Sukan F (2015) An optimization approach to scale up keratinase production by Streptomyces sp. 2M21 by utilizing chicken feather. Int Biodeterior Biodegrad 103:134–140. doi:10.1016/j.ibiod.2015.04.025

El-Naggar NEA, Moawad H, Abdelwahed NAM (2017) Optimization of fermentation conditions for enhancing extracellular production of L-asparaginase, an anti-leukemic agent, by newly isolated Streptomyces brollosae NEAE-115 using solid state fermentation. Ann Microbiol 67:1–15. doi:10.1007/s13213-016-1231-5

Fakhfakh N, Ktari N, Haddar A, Mnif IH, Dahmen I, Nasri M (2011) Total solubilisation of the chicken feathers by fermentation with a keratinolytic bacterium, Bacillus pumilus A1, and the production of protein hydrolysate with high antioxidative activity. Process Biochem 46:1731–1737. doi:10.1016/j.procbio.2011.05.023

Fakhfakh-Zouari N, Haddar A, Hmidet N, Frikha F, Nasri M (2010) Application of statistical experimental design for optimization of keratinases production by Bacillus pumilus A1 grown on chicken feather and some biochemical properties. Process Biochem 45:617–626. doi:10.1016/j.procbio.2009.12.007

Gessesse A, Hatti-Kaul R, Gashe BA, Mattiasson B (2003) Novel alkaline proteases from alkaliphilic bacteria grown on chicken feather. Enzym Microb Technol 32:519–524. doi:10.1016/S0141-0229(02)00324-1

Gupta R, Beg Q, Lorenz P (2002) Bacterial alkaline proteases: molecular approaches and industrial applications. Appl Microbiol Biotechnol 59:15–32. doi:10.1007/s00253-002-0975-y

Gupta R, Ramnani P (2006) Microbial keratinases and their prospective applications: an overview. Appl Microbiol Biotechnol 70:21–33. doi:10.1007/s00253-005-0239-8

Jeong JH, Jeon YD, Lee OM, Kim JD, Lee NR, Park GT, Son H (2010) Characterization of a multifunctional feather-degrading Bacillus subtilis isolated from forest soil. Biodegradation 21:1029–1040. doi:10.1007/s10532-010-9363-y

Kasana RC, Salwan R, Yadav SK (2011) Microbial proteases: detection, production, and genetic improvement. Crit Rev Microbiol 37:262–276. doi:10.3109/1040841X.2011.577029

Lange L, Huang Y, Busk PK (2016) Microbial decomposition of keratin in nature - a new hypothesis of industrial relevance. Appl Microbiol Biotechnol 100:2083–2096. doi:10.1007/s00253-015-7262-1

Lasekan A, Bakar FA, Hashim D (2013) Potential of chicken by-products as sources of useful biological resources. Waste Manag 33:552–565. doi:10.1016/j.wasman.2012.08.001

Lv LX, Sim MH, Li YD, Min J, Feng WH, Guan WJ, Li YQ (2010) Production, characterization and application of a keratinase from Chryseobacterium L99 sp. nov. Process Biochem 45:1236–1244. doi:10.1016/j.procbio.2010.03.011

Mabrouk MEM (2008) Feather degradation by a new keratinolytic Streptomyces sp. MS-2. World J Microbiol Biotechnol 24:2331–2338. doi:10.1007/s11274-008-9748-9

Matsui T, Yamada Y, Mitsuya H, Shigeri Y, Yoshida Y, Saito Y, Matsui H, Watanabe K (2009) Sustainable and practical degradation of intact chicken feathers by cultivating a newly isolated thermophilic Meiothermus ruber H328. Appl Microbiol Biotechnol 82:941–950. doi:10.1007/s00253-009-1880-4

Meriem G, Mahmoud K (2017) Optimization of chitinase production by a new Streptomyces griseorubens C9 isolate using response surface methodology. Ann Microbiol 67:175–183. doi:10.1007/s13213-016-1249-8

Mishra VK (2016) Optimization of thermotolerant alkaline protease production from Brevibacillus brevis strain BT2 using surface response methodology. Biocatal Agric Biotechnol 7:87–94. doi:10.1016/j.bcab.2016.05.008

Nawaz MA, Bibi Z, Karim A, Ur Rehman H, Jamal M, Jan T, Aman A, Ul Qader SA (2017) Production of α-1,4-glucosidase from Bacillus licheniformis KIBGE-IB4 by utilizing sweet potato peel. Environ Sci Pollut Res 24:4058–4066. doi:10.1007/s11356-016-8168-x

Park GT, Son HJ (2009) Keratinolytic activity of Bacillus megaterium F7-1, a feather-degrading mesophilic bacterium. Microbiol Res 164:478–485. doi:10.1016/j.micres.2007.02.004

Rajput R, Gupta R (2013) Thermostable keratinase from Bacillus pumilus KS12: production, chitin crosslinking and degradation of Sup35NM aggregates. Bioresour Technol 133:118–126. doi:10.1016/j.biortech.2013.01.091

Rieger TJ, De Oliveira CT, Pereira JQ, Brandelli A, Daroit DJ (2017) Proteolytic system of Bacillus sp. CL18 is capable of extensive feather degradation and hydrolysis of diverse protein substrates. Br Poult Sci. doi:10.1080/00071668.2017.1293229

Sahoo DK, Das A, Thatoi H, Mondal KC, Mohapatra PKD (2012) Keratinase production and biodegradation of whole chicken feather keratin by a newly isolated bacterium under submerged fermentation. Appl Biochem Biotechnol 167:1040–1051. doi:10.1007/s12010-011-9527-1

Sharma S, Gupta A (2016) Sustainable management of keratin waste biomass: applications and future perspectives. Braz Arch Biol Technol 59:e16150684. doi:10.1590/1678-4324-2016150684

Shih JCH, Williams CM (1990) Method of degrading keratinaceous material and bacteria useful therefore. US Patent number 4959311

Son HJ, Park HC, Kim HS, Lee CY (2008) Nutritional regulation of keratinolytic activity in Bacillus pumilis. Biotechnol Lett 30:461–465. doi:10.1007/s10529-007-9567-3

Suntornsuk W, Suntornsuk L (2003) Feather degradation by Bacillus sp. FK 46 in submerged cultivation. Bioresour Technol 86:239–243. doi:10.1016/S0960-8524(02)00177-3

Thanikaivelan P, Rao JR, Nair BU, Ramasami T (2004) Progress and recent trends in biotechnological methods for leather processing. Trends Biotechnol 22:181–188. doi:10.1016/j.tibtech.2004.02.008

Vermelho AB, Villa ALV, Almeida AMM, Dias EPS, Santos EP (2010) Keratin hydrolysates, process for their production and cosmetic composition containing the same. US Patent number 20100196302

Acknowledgments

Authors thank the “Programa Institucional de Iniciação Científica da Universidade Federal da Fronteira Sul (PRO-ICT/UFFS)” and “Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul (PROBIC/FAPERGS).”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Santiago V. Luis

Rights and permissions

About this article

Cite this article

Sobucki, L., Ramos, R.F. & Daroit, D.J. Protease production by the keratinolytic Bacillus sp. CL18 through feather bioprocessing. Environ Sci Pollut Res 24, 23125–23132 (2017). https://doi.org/10.1007/s11356-017-9876-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9876-6