Abstract

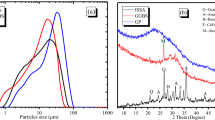

This study evaluated the feasibility of production of briquettes using fine charcoal, sewage sludge, and mixtures thereof for use in energy production. The briquettes of 7–8 cm diameter and 20 cm length were produced in the conical press extruder type, mixing sewage sludge to charcoal fines in different ratios: 0:100, 25:75, 50:50, 75:25, and 100:0, with the addition of a binder (glue flour) in a ratio of 8 mass% prepared for briquetting. After air drying (temperatures between 24 and 30°C) for 48 h, the mechanical, thermal, and morphological characterizations were performed. The morphological properties of the briquettes were evaluated by scanning electron microscopy (SEM) and Fourier transform infrared (FTIR) spectroscopy. The briquettes produced had mechanical strength, with values between 210 and 420 kgf, and densities between 0.75 and 0.91 g cm−3. The calorific value of briquettes was in the range from 13.21 to 23.10 MJ kg−1, in which there was an increase with the increase of concentration of charcoal fines in the mixture. Thermogravimetric analysis showed mass losses that occurred in the temperature range between 150 and 740 °C. The results of the mechanical and thermal properties showed the feasibility of using fine charcoal briquettes from sewage sludge as well as mixtures thereof, for the production of energy. The fine charcoal briquette was the one with the highest calorific value, but not showed the highest resistance to mechanical shock.

Similar content being viewed by others

References

Adelopo AO, Haris PI, Alo B Huddersman K, Jenkins RO (2016) Comparative characterisation of closed and active landfill composites using EDX, FTIR and proximate techniques. Waste Biomass Valoriz. doi:10.1007/s12649-016-9673-3

Alakangas E, Wiik C, Lensu T (2007) CEN 335–Solid biofuels, feedback from market actors, EUBIONET report–VTT Report VTTR-00430-07, Jyväskylä 2007

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT) (1981) NBR 6922 - Carvão vegetal - ensaios físicos - determinação da massa específica (densidade a granel). Rio de Janeiro, p 2

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT) (2007) NBR 5739 -Concreto-Ensaios de compressão de corpos-de-prova cilíndricos

ASTM D240-02 (2007) Standard test method for heat of combustion of liquid hydrocarbon fuels by bomb calorimeter. Annual Book of ASTM Standards 5:117–124

Araújo S, Boas MAV, Neiva DM, de Cassia CA, Vital B, Breguez M, Pereira H (2016) Effect of a mild torrefaction for production of eucalypt wood briquettes under different compression pressures. Biomass Bioenergy 90:181–186

Bhattacharya SC, Leon MA, Rahman MM (2002) A study on improved biomass briquetting. Energy for sustainable development, Bangalore 6(2):67–71

Bianchini A, Bonfiglioli L, Pellegrini M, Saccani C (2015) Sewage sludge drying process integration with a waste-to-energy power plant. Waste Manag 42:159–165

CEN/TS 14961 (2005) Solid biofuels. Fuel specifications and classes. British Standards Institution, London, p 46

Chen Y, Zhi G, Feng Y, Tian C, Bi X, Li J, Zhang G (2015) Increase in polycyclic aromatic hydrocarbon (PAH) emissions due to briquetting: a challenge to the coal briquetting policy. Environ Pollut 204:58–63

De Sena RF, Claudino A, Moretti K, Bonfanti ÍC, Moreira RF, José HJ (2008) Biofuel application of biomass obtained from a meat industry wastewater plant through the flotation process—a case study. Resour Conserv Recycl 52(3):557–569

Diez MA, Alvarez R, Cimadevilla JLG (2013) Briquetting of carbon-containing wastes from steelmaking for metallurgical coke production. Fuel 114:216–223. doi:10.1016/j.fuel.2012.04.018

Grover PD, Mishra, SK (1996) Biomass briquetting: technology and practices. Food and Agriculture Organization of the United Nations. Bangkok, Thailand. From FAO Publications, 46 (2000): http://www.fao.org/docrep/006/ad579e/ad579e00.pdf (accessed 06 April 2015)

Hu J, Lei T, Wang Z, Yan X, Shi X, Li Z, He X, Zhang Q (2014) Economic, environmental and social assessment of briquette fuel from agricultural residues in China—a study on flat die briquetting using corn stalk. Energy 64:557–566

Jiang J, Du X, Yang S (2010) Analysis of the combustion of sewage sludge-derived fuel by a thermogravimetric method in China. Waste Manag 30(7):1407–1413

Jiang L, Liang J, Yuan X, Li H, Li C, Xiao Z, Huang H, Wang H, Zeng G (2014) Co-pelletization of sewage sludge and biomass: the density and hardness of pellet. Bioresour Technol 166:435–443

Kijo-Kleczkowska A, Środa K, Kosowska-Golachowska M, Musiał T, Wolski K (2016) Combustion of pelleted sewage sludge with reference to coal and biomass. Fuel 170:141–160

Kim M, Lee Y, Park J, Ryu C, Ohm TI (2016) Partial oxidation of sewage sludge briquettes in a updraft fixed bed. Waste Manag 49:204–211

Kosturkiewicz B, Janewicz A, Magdziarz A (2014) Results of briquetting and combustion process on binder-free coking coal. Pol J Environ Stud 23(4):1385–1389

Lela B, Barišić M, Nižetić S (2016) Cardboard/sawdust briquettes as biomass fuel: physical–mechanical and thermal characteristics. Waste Manag 47:236–245

Long Y, Ruan L, Lv X, Lv Y, Su J, Wen Y (2015) TG–FTIR analysis of pyrolusite reduction by major biomass components. Chin J Chem Eng 23(10):1691–1697

Magdziarz A, Werle S (2014) Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manag 34(1):174–179

Muazu RI, Stegemann JA (2015) Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process Technol 133:137–145

Oladeji JT, Enweremadu CC (2012) The effects of some processing parameters on physical and densification characteristics of corncob briquettes. International Journal of Energy Engineering 2(1):22–27

Olorunnisola A (2007) Production of fuel briquettes from waste paper and coconut husk admixtures. Agricultural Engineering International: the CIGR Ejournal. Manuscript EE 06 006, 9:1–12

Sänger M, Werther J, Ogada J (2001) NOx and N2O emission characteristics from fluidized bed combustion of semi-dried municipal sewage sludge. Fuel 80:167–177

Srivastava NSL, Narnaware SL, Makwana JP, Singh SN, Vahora S (2014) Investigating the energy use of vegetable market waste by briquetting. Renew Energy 68:270–275

Sun B, Yu J, Tahmasebi A, Han Y (2014) An experimental study on binderless briquetting of Chinese lignite: effects of briquetting conditions. Fuel Process Technol 124:243–248

Stolarski MJ, Szczukowski S, Tworkowski J, Krzyżaniak M, Gulczyński P, Mleczek M (2013) Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew Energy 57:20–26

Teixeira SR, Pena AFV, Miguel AG (2010) Briquetting of charcoal from sugar-cane bagasse fly ash (SCBFA) as an alternative fuel. Waste Manag 30(5):804–807

Wzorek M (2012) Characterisation of the properties of alternative fuels containing sewage sludge. Fuel Process Technol 104:80–89

Yank A, Ngadi M, Kok R (2016) Physical properties of rice husk and bran briquettes under low pressure densification for rural applications. Biomass Bioenergy 84:22–30

Zheng G, Koziń Ski JA (2000) Thermal events occurring during the combustion of biomass residue. Fuel 79(2):181–192

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

de Oliveira, R.S., Palácio, S.M., da Silva, E.A. et al. Briquettes production for use as power source for combustion using charcoal thin waste and sanitary sewage sludge. Environ Sci Pollut Res 24, 10778–10785 (2017). https://doi.org/10.1007/s11356-017-8695-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-8695-0