Abstract

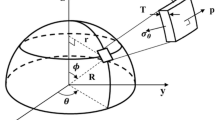

The purpose of this study was to examine the effects of the geometries and dimensions of the rig and specimen of a small punch (SP) test on the determined creep property. The SP creep property of a specimen was evaluated using finite element analysis by varying the specimen thickness and diameter, diameter of the spherical and hemispherical indentation punches, inner diameter of the lower die, and dimensions of the chamfer of the lower die. We observed that the rupture time decreased with decreasing specimen thickness and punch diameter and with increasing chamfer size and inner diameter of the lower die. Under similar analytical conditions of static average equivalent stress in steady state, the SP creep curves reasonably agreed even in the case where the specimens or rigs have different geometries, which implied the possibility of direct comparison of the test results obtained from specimens and rigs with different dimensions and geometries.

Similar content being viewed by others

References

Parker JD, James JD (1994) Creep behavior of miniature. Disc specimens of low alloy steel. Developments in a Progressing Technology ASME 279:167–172

Komazaki S, Hashida T, Shoji T, Suzuki K (2000) Development of small punch tests for creep property measurement of tungsten-alloyed 9% Cr ferritic steels. ASTM Journal of Testing and Evaluation(USA) 28(4):249–256

Nakata T, Komazaki S, Kohno Y, Tanigawa H (2016) Development of a small punch testing method to evaluate the creep property of high Cr ferritic steel: part I—effect of atmosphere on creep deformation behavior. Mater Sci Eng A 666:54–60. doi:10.1016/j.msea.2016.03.100

Kanaya A, Nagae M, Kusumoto J, Miyamoto T, Kobayash T (2005) The application of on-site sampling machine to SPC test for thermal power plant. The Japan Society of Mechanical Engineers annual meeting 2005(5):335–336

Sugimoto T, Doki K, Komazaki S, Misawa T (2005) Evaluation of toughness and creep properties of aged main valve CrMoV casting steel by using small punch specimens(mechanical properties). Tetsu- to- Hagane 91(4):408–414

Komazaki S, Sugimoto T, Hasegawa Y, Kohno Y (2007) Damage evaluation of a welded joint in a long-term service-exposed boiler by using a small punch creep test. ISIJ Int 47(8):1228–1233

Komazaki S, Kato T, Kohno Y, Tanigawa H (2009) Creep property measurements of welded joint of reduced-activation ferritic steel by the small-punch creep test. Mater Sci Eng A 510-511:229–233

Ito T, Nonaka I (2005) Application trial of small punch test for assessment of creep property. Ishikawajima-Harima Engineering Review 45(2):86–90

Tettamanti S, Crudeli R (1999) A procedure for high temperature plant components life evaluation: small punch creep test methodology. Proceedings of an International Symposium on Case Histories on Integrity and Failure Industry. The Italian Group on Fracture (IGF) and ENEL Research (Milan-I)

Milička K, Dobeš F (2006) Small punch testing of P91 steel. Int J Press Vessel Pip 83(9):625–634

Hurst R, Bicego V, Foulds I (2007) Small punch testing for creep - progress in Europe. Proceedings of Creep8 Eighth International Conference on Creep and fatigue at Elevated Temperatures CREEP2007–26693:1–6

Ule B, Sustar T, Dobes F, Milicka K, Bicego V, Tettamanti S, Maile K, Schwarzkopf C, Whelan MP, Kozlowski RH, Klaput J (1999) Small punch test method assessment for the determination of the residual creep life of service exposed components: outcomes from an interlaboratory exercise. Nucl Eng Des 192(1):1–11

Kobayashi K, Toda K, Stratford GC, Wilshire B (2007) A development of small punch creep (SPC) testing apparatus, and feature of creep deformation and rupture by the SPC test. Journal of High Pressure Institute of Japan 45(4):180–186

Yoon KB, Park TG, Shim SH, Jeong IS (2001) Assessment of creep properties of 9Cr steel using small punch creep testing. Transactions of the KSME, A 25(12):1493–1500

Yang Z, Wang Z-w (2003) Relationship between strain and central deflection in small punch creep specimens. Int J Press Vessel Pip 80(6):397–404

Ling X, Zheng Y, You Y, Chen Y (2007) Creep damage in small punch creep specimens of type 304 stainless steel. Int J Press Vessel Pip 84(5):304–309

Zhai P, Hashida T, Komazaki S, Zhang Q (2004) Numerical analysis for small punch creep tests by finite-element method. J Test Eval 32(4):298–303

Kohno Y (2000) The evaluation of mechanical properties by means of small specimen test technology. J Plasma Fusion Res 76(4):368–375

Zhou Z, Zheng Y, Ling X, Hu R, Zhou J (2010) A study on influence factors of small punch creep test by experimental investigation and finite element analysis. Mater Sci Eng A 527(10–11):2784–2789. doi:10.1016/j.msea.2010.01.010

Nakata T, Komazaki S, Kohno Y, Tanigawa H (2016) Development of a small punch testing method to evaluate the creep property of high Cr ferritic steel: part II – stress analysis of small punch test specimen by finite element method. Mater Sci Eng A 666:80–87. doi:10.1016/j.msea.2016.03.102

Nakata T, Tanigawa H, Shiba K, Komazaki S, Fujiwara M, Kohno Y, Kohyama A (2007) Evaluation of creep properties of reduced activation ferritic steels. J Jpn Inst Metals 71(2):239–243

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakata, T., Komazaki, S., Kohno, Y. et al. Effects of Geometry and Dimension of Specimen and Rig on Small Punch Creep Property. Exp Mech 57, 487–494 (2017). https://doi.org/10.1007/s11340-016-0250-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0250-2