Abstract

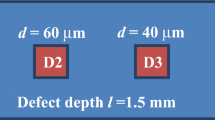

An experimental method is proposed for obtaining the fracture toughness of an interfacial crack in sandwich structures. The method relates the interfacial fracture toughness with temperature change developed at the crack front. The focus of the paper is the development of an experimental approach that uses high speed infrared (IR) thermography to capture the temperature evolution during the crack growth. The feasibility of using IR thermography is demonstrated on sandwich structure specimens with E-glass/epoxy face sheets and cross-linked PVC H100 foam core loaded in mixed-mode bending. Different crack propagation paths, in the foam core and at the face sheet/core interface are considered. It is shown that IR thermography with 15 kHz frame rate is able to make a quantitative measurement of the crack front temperature associated with the crack growth. A constant of proportionality ψ is derived between the temperature change per unit area at the crack front and the fracture toughness provided by a validated FE model. It is shown that ψ obtained from specimens with the same crack propagation path is identical, even though the specimen dimensions and loading mode-mixities are different. Thus, it is demonstrated that for a particular interface, once ψ is obtained from a known loading condition, the interfacial fracture toughness from any loading configuration can be determined from a direct temperature measurement.

Similar content being viewed by others

References

Zenkert D (1997) An introduction to sandwich construction. EMAS, London

Berggreen C (2004) Damage tolerance in debonded sandwich structures, Ph.D. Thesis, Department of Mechanical Engineering, Technical University of Denmark, Denmark.

Kulkarni N, Mahfuz H, Jeelani S, Carlsson LA (2003) Fatigue crack growth and life prediction of foam core sandwich composites under flexural loading. Compos Struct 59(4):499–505

Liechti KM, Chai YS (1992) Asymmetric shielding in interfacial fracture under in-plane shear. J Appl Mech 59:295–304

Li X, Carlsson LA (2001) Fracture mechanics analysis of tilted sandwich debond (TSD) specimen. J Compos Mater 35:2145–2168

Quispitupa A, Berggreen C, Carlsson LA (2009) On the analysis of a mixed mode bending sandwich specimen for debond fracture characterization. J Sandwich Struct Mater 76(4):594–613

Quispitupa A, Berggreen C, Carlsson LA (2011) Face/core interface fracture characterization of mixed of mixed mode bending sandwich specimens. Fatigue Fract Eng Mater Struct 34(11):839–853

Li X, Carlsson LA (1999) The tilted sandwich debond (TSD) specimen for face/core interface fracture characterization. J Sandwich Struct Mater 1(1):60–75

Bramson MA (1968) Infrared radiation: A handbook for applications. Plenum, New York

Loya JA, Villa EI, Fernandez-Saez J (2010) Crack-front propagation during three-point-bending tests of polymethyl-methacrylate beams. Polym Test 29:113–118

Fruehmann RK, Crump DA, Dulieu-Barton JM (2013) Characterization of an infrared detector for high frame rate thermography. Meas Sci Technol 24(10):105403

Griffith AA (1920) The phenomena of rupture and flow in solids. Phil Trans R Soc A 221:163–198

Irwin GR (1956) Onset of fast crack propagation in high strength steel and aluminium alloys. Sagamore Res Conf Proc 2:289–305

Farahmand B (2001) Fracture mechanics of metals, composites, welds, and bolted joints: application of LEFM, EPFM, and FMDM theory. Kluwer, US

Taylor GI, Quinney H (1934) The latent energy remaining in a metal after cold working. Proc R Soc A 143:307–326

A. Engelter, F.H. Muller, Kolloid Z (1958) 157 (89)

Saenz EE, Carlsson LA, Karlsson A (2011) Characterization of fracture toughness (G c ) of PVC and PES foams. J Mater Sci 46(9):3207–3215

Maiti SK, Ashby MF, Gibson LJ (1984) Fracture toughness of brittle cellular solids. Scr Metall 18(3):213–217

Kelly FJ (1966) An equation for the local thermal emissivity at the vertex of a diffuse conical or v-groove cavity. Appl Opt 5(6):925–927

Zhang S, Dulieu-Barton JM, Fruehmann RK, Thomsen OT (2012) A methodology for obtaining material properties of polymeric foam at elevated temperatures. Exp Mech 52:3–15

Manca M, Quispitupa A, Berggreen C, Carlsson LA (2012) Face/core debond fatigue crack growth characterization using the sandwich mixed mode bending speicmen. Compos Part A: Appl Sci Manuf 43(11):2120–2127

http://www.instron.us/wa/acc_catalog/prod_list.aspx?cid=1165&cname=2580%20Series%20 load%20Cells, accessed in 2014

Suo Ζ (1990) Singularities, interfaces and cracks in dissimilar anisotropic media. Proc R Soc A 427(1873):331–358

Østergaard RC, Sørensen BF, Brøndsted P (2007) Measurement of interface fracture toughness of sandwich structures under mixed mode loadings. J Sandwich Struct Mater 9(5):445–466

Hutchinson JW, Suo Z (1992) Mixed mode cracking in layered materials. Adv Appl Mech 29:63–191

Berggreen C, Simonsen BC (2005) Non-uniform compressive strength of debonded sandwich of debonded sandwich panels-II. Fracture mechanics investigation. J Sandwich Struct Mater 7:483–517

ANSYS 12.1 manual, ANSYS Inc Canonsburg, (2009)

Berggreen C, Simonsen BC, Borum KK (2007) Experimental and numerical study of interface crack propagation in foam cored sandwich beams. J Compos Mater 41(4):493–520

Acknowledgments

The work presented was co-sponsored by the University of Southampton and the Danish Council for Independent Research | Technology and Production Sciences (FTP), under the research project ‘Enhanced Performance of Sandwich Structures by Improved Damage Tolerance’ (‘SANTOL’). The financial support received is gratefully acknowledged. The foam material supported by DIAB AB Sweden is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Dulieu-Barton, J.M. & Thomsen, O.T. A Methodology for Characterizing the Interfacial Fracture Toughness of Sandwich Structures using High Speed Infrared Thermography. Exp Mech 56, 121–132 (2016). https://doi.org/10.1007/s11340-015-0023-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0023-3