Abstract

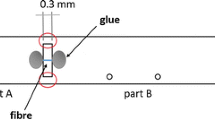

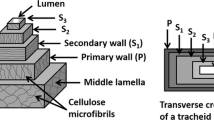

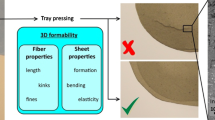

The strength properties of interfibre bonds play a vital role in the response of fibrous materials, such as paper and paperboard, under mechanical loading. To help tailor the properties of such materials by chemical or mechanical treatments of the fibre wall and fibre surfaces, improved understanding of the microscopic damage and failure mechanisms of interfibre joints is desirable. In this paper, a method for manufacturing and testing of interfibre joint specimens in two principally different modes of loading is presented. The method was applied to investigate the strength of Kraft pulp interfibre joints with different geometries and in two different modes of loading: the conventional shearing mode and also a peeling mode of loading. The method was also used to investigate the influence of drying pressure, defined as the nominal pressure between two Teflon surfaces or between a rubber surface and a Teflon one as well as a simple comparison of a pulp with two different degrees of refining. The results are presented in terms of rupture force and using different methods of normalization such as nominal overlap area, length, and width of the joint region, measured using a microscope. It was shown in this study that normalising the force at rupture by either geometric parameter reduced the scatter of the strength measurements slightly, but, neither were unambiguously more successful than the other. The results of tests done with the peeling type of loading were about 20 % of those done with the conventional shearing type of loading.

Similar content being viewed by others

References

Torgnysdotter A, Wågberg L (2003) Study of the joint strength between regenerated cellulose fibres and its influence on the sheet strength. Nord Pulp Pap Res J 18:455–459

Page DH (1960) Fibre-to-fibre bonds Part 1–a method for their direct observation. Pap Technol 1:407–411

Page DH, El-Hosseiny F, Winkler K, Bain R (1972) The mechanical properties of single wood-pulp fibres. Part 1: a new approach. Pulp Pap Mag Can–Tech Pap T198(73):72–77

El-Hosseiny F, Page DH (1975) The mechanical properties of single wood pulp fibres: theories of strength. Fibre Sci Technol 8:21–31

Hill R (1950) The mathematical theory of plasticity. Oxford University Press, New York, pp 317–340

Page DH, Seth RS (1980) The elastic modulus of paper III. The effects of dislocations, microcompressions, curl, crimps, and kinks. Tappi J 63:99–102

Page DH, Seth RS, Jordan BD, Barbe MC (1985) Curl, crimps, kinks and microcompressions in pulp ribres–their origin, measurement and significance. Transactions of the VIIIth Fundamental Res. Symposium, Oxford

Page DH (1969) A theory for the tensile strength of paper. Tappi J 52:674–681

Seth RS (2006) The importance of fibre straightness for pulp strength. Pulp Pap Can 107:34–42

Mayhood CH, Kallmes OJ, Cauley MM (1962) The mechanical properties of paper–part II: measured shear strength of individual fiber to fiber contacts. Tappi J 45:69–73

McIntosh DC (1963) Tensile and bonding strengths of loblolly pine Kraft fibers cooked to different yields. Tappi J 46:273–277

Mohlin U (1974) Cellulose fibre bonding. Svensk Papperstidning 4:131–137

Schniewind AP, Nemeth LJ, Brink DL (1964) Fiber and pulp properties–1. Shear strength of single-fiber crossings. Tappi J 47:244–248

Nordman LS (1957) Bonding in paper sheets. In: Fundamentals of papermaking fibres. Transactions of the Cambridge Symposium

Page DH (2002) The meaning of Nordman bond strength. Nord Pulp Pap Res J 17:39–44

Retulainen E, Ebeling K (1993) Fibre–fibre bonding and ways of characterizing bond strength. Appita 46:282–288

Skowronski J (1991) Fibre-to-fibre bonds in paper. Part II: measurement of the breaking energy of fibre-to-fibre bonds. J Pulp Pap Sci 17:217–222

Clark JD (1978) Pulp technology and treatment for paper. Miller Freeman Publications, San Francisco

Internal bond strength (Scott type), Test Method T 569 om-09. Tappi Press, Atlanta

Joshi K, Batchelor W, Rasid KA (2011) Investigation of the effect of drying and refining on the fiber–fiber shear bond strength measured using tensile fracture line analysis of sheets weakened by acid gas exposure. Cellulose 18:1407–1421

Stratton RA, Colson NL (1990) Dependence of fiber/fiber bonding on some papermaking varables, IPST Technical Paper Series. Institute of Paper Science and Technology, Atlanta

Taegeun K, Paulapuro H, Hiltunen E (2004) Fracture mechanism in interfibre bond failure–microscopic observations. Appita J 57:199–203

Thorpe JL, Mark RE, Esufzai ARK, Perkins RW (1976) Mechanical properties of fiber bonds. Tappi J 59:96–100

Button AF (1979) Fiber–fiber bond strength–a study of a linear elastic model structure. Atlanta

Efron B, Tibshirani RJ (1993) An introduction to the bootstrap. Chapman & Hall, New York

Schmied FJ, Teichert C, Kappel L, Hirn U, Schennach R (2012) Joint strength measurements of individual fiber–fiber bonds: an atomic force microscopy based method. Rev Sci Instrum 83:073902-1–073902-8

Stratton RA, Colson NL (1993) Fiber wall damage during bond failure. Nord Pulp Pap Res J 2:245–257

Torgnysdotter A, Kulachenko A, Gradin P, Wågberg L (2007) Fiber/fiber crosses: finite element modeling and comparison with experiment. J Compos Mater 41:1603–1618

Torgnysdotter A, Kulachenko A, Gradin P, Wågberg L (2007) The link between the fiber contact zone and the physical properties of paper: a way to control paper properties. J Compos Mater 41:1619–1633

Kappel L, Hirn U, Gilli E, Baur W, Schennach R (2010) Revisiting polarized light microscopy for fiber–fiber bond area measurment–part II: proving the applicability. Nord Pulp Pap Res J 25:71–75

Kappel L, Hirn U, Gilli E, Baur W, Schennach R (2010) Revisiting polarized light microscopy for fiber–fiber bond area measurment–part I: theoretical fundamentals. Nord Pulp Pap Res J 25:65–70

Saketi P, Kallio P (2011) Microrobotic platform for making, manipulating and breaking individual paper fiber bonds. In: Assembly and manufacturing (ISAM). 2011 IEEE International symposium

Bäckström M, Bolivar S, Paltakari J (2012) Effect of ionic form on fibrillation and the development of the fibre network strength during the refining of the kraft pulps. Rev Pap 73:57–65

Abramoff MD, Magelhaes PJ, Ram SJ (2004) Image processing with imageJ. Biophoton Int 11:36–42

Schmied FJ, Ganser C, Fischer W, Hirn U, Bauer W, Schennach R, Teichert C (2012) Utilizing atomic force microscopy to characterize various single fiber–fiber bonds. In: 8th international paper and coating chemistry symposium. Stockholm Sweden

Russel J, Kallmes OJ, Mayhood CH (1964) The influence of two wet strength. Tappi J 47:22–25

Torgnysdotter A, Wågberg L (2006) Tailoring of fibre/fibre joints in order to avoid the negative impacts of drying on paper properties. Nord Pulp Pap Res J 21:411–418

Acknowledgments

The authors also would like to acknowledge the financial support provided by BiMaC Innovation and the Swedish Research Council (project grant 2007-5380). The contributions of Marie Bäckstrm and Professor Lars Wågberg in providing pulps, and the discussions on statistical methods together with Professor Tatjana Pavlenko are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Magnusson, M., Zhang, X. & Östlund, S. Experimental Evaluation of the Interfibre Joint Strength of Papermaking Fibres in Terms of Manufacturing Parameters and in Two Different Loading Directions. Exp Mech 53, 1621–1634 (2013). https://doi.org/10.1007/s11340-013-9757-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9757-y