Abstract

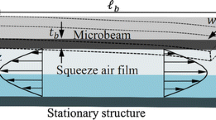

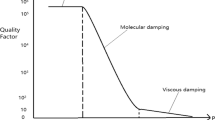

High quality factor of dynamic structures at micro and nano scale is exploited in various applications of micro electro-mechanical systems (MEMS) and nano electro-mechanical system. The quality factor of such devices can be very high in vacuum. However, when vacuum is not desirable or not possible, the tiny structures must vibrate in air or some other gas at pressure levels that may vary from atmospheric to low vacuum. The interaction of the surrounding fluid with the vibrating structure leads to dissipation, thus bringing down the quality factor. Depending on the ambient fluid pressure or the gap between the vibrating and the fixed structure, the fluid motion can range from continuum flow to molecular flow giving a wide range of dissipation. The relevant fluid flow characteristics are determined by the Knudsen number which is the ratio of the mean free path of the gas molecule to the characteristic flow length of the device. This number is very small for continuum flow and reasonably big for molecular flow. In this paper, we study the effect of fluid pressure on the quality factor by carrying out experiments on a MEMS device that consists of a double gimbaled torsional resonator. Such devices are commonly used in optical cross-connects and switches. We only vary fluid pressure to make the Knudsen number go through the entire range of continuum flow, slip flow, transition flow, and molecular flow. We experimentally determine the quality factor of the torsional resonator at different air pressures ranging from 760 Torr to 0.001 Torr. The variation of this pressure over six orders of magnitude ensures required rarefaction to range over all flow conditions. Finally, we get the variation of quality factor with pressure. The result indicates that the quality factor, Q, follows a power law, Q ∝P –r , with different values of the exponent r in different flow regimes. In the second part of the paper, we propose the use of effective viscosity for considering velocity slip conditions in solving Navier–Stokes equation numerically. This concept is validated with analytical results for a simple case and then compared with the experimental results presented in this paper. The study shows that the effective viscosity concept can be used effectively even for the molecular regime if the air-gap to length ratio is sufficiently small (h 0/L<0.01). As this ratio increases, the range of validity decreases.

Similar content being viewed by others

References

Craighead HG (2000) Nanoelectromechanical systems. Science 290(5496):1532–1535.

Ilic B, Yang Y, Craighead HG (2004) Virus detection using naoelectromechanical devices. Appl Phys Lett 85(1313): 2604–2606.

Verbridge SS, Parpia JM, Reichenbach RB, Bellan LM, Craighead HG (2006) High quality factor resonance at room temperature with nanostrings under high tensile stress. J Appl Phys 99:124304–124308.

Blom FR, Bouwstra S, Elwenspoek M, Fluitman JHJ (1992) Dependence of the quality factor of micromachined silicon beam resonators on pressure and geometry. J Vac Sci Tech B 10(1):19–26.

Langlois WE (1962) Isothermal squeeze films. Q Appl Math 20(2):131–150.

Griffin WS, Richardsen HH, Yamamami S (1966) A study of fluid squeeze film damping. J Basic Eng 88:451–456.

Blech JJ (1983) On isothermal squeeze films. J Lubr Technol 105:615–620.

Pan F, Kubby J, Peeters E, Tran AT, Mukherjee S (1998) Squeeze film damping effect on the dynamic response of a MEMS torsion mirror. J Micromechanics Microengineering 8:200–208.

Chang K-M, Lee S-C, Li S-H (1999) Squeeze film damping effect on a MEMS torsion mirror. J Micromechanics Microengineering 9(1):89–96.

Minikes A, Bucher I, Avivi G (2005) Damping of a micro-resonator torsion mirror in rarefied gas ambient. J Micromechanics Microengineering 15:1762–1769.

Huang JM, Liu AQ, Deng ZL, Zhang QX, Ahn J, Asundi A (2004) An approach to the coupling effect between torsion and bending for electrostatic torsional micromirrors. Sens Actuators A Phys 115:159–167.

Zhou G, Tay FEH, Chau FS (2003) Macro-modelling of a double-gimbaled electrostatic torsional micromirror. J Micromechanics Microengineering 13:532–547.

Arkilic EB, Breuer KS (1993) Gaseous flow in small channels. AIAA Pap 93:3270-1–7.

Arkilic EB, Breuer KS, Schmidt MA (2001) Mass flow and tangential momentum accommodation in silicon micromachined channels. J Fluid Mech 437:29–43.

Colin S (2005) Rarefaction and compressibility effects on steady and transient gas flows in microchannels. Microfluid Nanofluid 1:268–279.

Kogan MN (1969) Rarified gas dynamics. Plenum, New York.

Sharipov F (1999) Non-isothermal gas flow through rectangular microchannels. J Micromechanics Microengineering 9:394–401.

Bird GA (1996) Molecular gas dynamics and the direct simulation of gas flows. Oxford University Press, Oxford.

Beskok A, Karniadakis GE (1999) A model for flows in channels, pipes, and ducts at micro and nano scales. Microscale Thermophys Eng 3(1):43–77.

Batchelor GK (1997) An introduction to fluid dynamics. Cambridge University Press, Cambridge.

Pan LS, Liu GR, Lam KY (1999) Determination of slip coefficient for rarefied gas flows using direct simulation Monte Carlo. J Micromechanics Microengineering 9(1):89–96.

Piekos ES, Breuer KS (1996) Numerical modeling of micromechanical devices using the direct simulation Monte Carlo method. J Fluids Eng 118:464–469.

Sharipov F, Seleznev V (1998) Data on internal rarefied gas flows. J Phys Chem Ref Data 27(3):657–706.

Cercignani C (1998) The boltzmann equation and its application. Springer, New York.

Li W-L (1999) Analytical modeling of ultra-thin gas squeeze film. Nanotechnology 10(4):440–446.

Karniadakis GE, Beskok A (2001) Micro flows: fundamental and simulation. Springer, New York.

Bhatnagar P, Gross K, Krook K (1954) A model for collision processes in gasses. Phys Rev 94:511–524.

Cercignani C, Illner R, Pulvirenti M (1994) The mathematical theory of dilute gases, vol. 106. Springer, New York.

Grad H (1949) On the kinetic theory of rarefied gases. Commun Pure Appl Math 2:331–407.

Veijola T, Pursula A, Ráback P (2005) Extending the validity of squeezed-film damper models with elongations of surface dimensions. J Micromechanics Microengineering 15:1624–1636.

Pandey AK, Pratap R, Chau FS (2007) Analytical solution of modified Reynolds equation in perforated MEMS structures. Sens Actuators A Phys 135:839–848.

Pandey AK, Pratap R (2007) A comparative study of analytical squeeze film damping models in rigid rectangular perforated MEMS structures with experimental results. Microfluid Nanofluid, doi:10.1007/s10404-007-0165-4.

Rao SS (1995) Mechanical vibration. Wesley, New York.

Mohanty P, Harrington DA, Ekinci KL, Yang YT, Murphy MJ, Roukes ML (2002) Intrinsic dissipation in high-frequency micromechanical resonators. Phys Rev B 66:085416-1–15.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, A.K., Pratap, R. & Chau, F.S. Effect of Pressure on Fluid Damping in MEMS Torsional Resonators with Flow Ranging from Continuum to Molecular Regime. Exp Mech 48, 91–106 (2008). https://doi.org/10.1007/s11340-007-9076-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-007-9076-2