Abstract

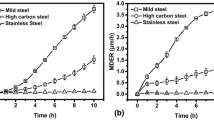

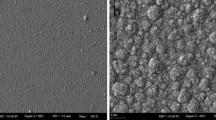

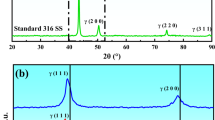

The cavitation erosion and corrosion characteristic of a nickel-free high-nitrogen stainless steel (HNSS) in distilled water and 0.5 mol/L HCl solution were investigated by conducting gravimetric and electrochemical measurements, including corrosion potential, polarization curves and electrochemical impedance spectroscopy, and the eroded/corroded surface was observed by scanning electron microscopy. The results revealed that the dominant contribution to cavitation erosion damage was the mechanical degradation process, even though the corrosion rate of HNSS was accelerated in 0.5 mol/L HCl solution. Corrosion and mechanical degradation worked synergistically and promoted crack initiation and propagation under cavitation erosion.

Similar content being viewed by others

References

Liu, W., Zheng, Y.G., Liu, C.S., Yao, Z.M., Ke, W.: Cavitation erosion behavior of Cr–Mn–N stainless steels in comparison with 0Cr13Ni5Mo stainless steel. Wear 254, 713–722 (2003)

Mesa, D.H., Garzon, C.M., Tschiptschin, A.P.: Influence of cold-work on the cavitation erosion resistance and on the damage mechanisms in high-nitrogen austenitic stainless steels. Wear 271, 1372–1377 (2011)

Qiao, Y.X., Wang, S., Liu, B., Zheng, Y.G., Li, H.B., Jiang, Z.H.: Synergistic effect of corrosion and cavitation erosion of high nitrogen stainless steel. Acta Metall. Sin. 52, 233–240 (2016)

Qiao, Y.X., Cai, X., Cui, J., Tang, Y.B., Li, H.B., Jiang, Z.H.: Cavitation erosion properties of a nickel-free high-nitrogen Fe–Cr–Mn–N stainless steel. Mater. Technol. 51, 933–938 (2017)

Al-Hashem, A., Caceres, P.G., Abdullah, A., Shalaby, H.M.: Cavitation corrosion of duplex stainless steel in seawater. Corrosion 53, 103–113 (1997)

Kwok, C.T., Cheng, F.T., Man, H.C.: Synergistic effect of cavitation erosion and corrosion of various engineering alloys in 3.5% NaCl solution. Mater. Sci. Eng. A 290, 145–154 (2000)

Lo, K.H., Kwok, C.T., Wang, K.Y., Ai, W.J.: Implications of solution treatment on cavitation erosion and corrosion resistances and synergism of austenitic stainless steel. Wear 392–393, 159–166 (2017)

Zheng, Y.G., Luo, S.Z., Ke, W.: Cavitation erosion–corrosion behaviour of CrMnB stainless overlay and 0Cr13Ni5Mo stainless steel in 0.5 M NaCl and 0.5 M HCl solutions. Tribol. Int. 41, 1181–1189 (2008)

Wang, B.C.: Zhu. J.H.: Influence of ultrasonic cavitation on passive film of stainless steel. Ultrason. Sonochem. 15, 239–243 (2008)

Bregliozzia, G., Di-Schino, A., Ahmed, S.I.U., Kenny, J.M., Haefke, H.: Cavitation wear behaviour of anstenitic stainless steels with differebt grain sizes. Wear 258, 503–510 (2005)

Kwok, C.T., Man, H.C., Leung, L.K.: Effect of temperature, pH and sulphide on the cavitation erosion behaviour of super duplex stainless steel. Wear 211, 84–93 (1997)

Cheng, F.T., Shi, P., Man, H.C.: Effect of electrolytic hydrogen pre-charging on the cavitation erosion resistance of NiTi: a preliminary study. Scripta Mater. 47, 89–94 (2002)

Karimi, A., Martin, J.L.: Cavitation erosion of materials. Int. Met. Rev. 31, 1–26 (1986)

ASTM G32-10: Standard Test Method for Cavitation Erosion Using Vibratory Apparatus. West Conshohocken: ASTM International (2010). http://www.astm.org

Mitelea, I., Micu, L.M., Bordeasşu, I., Crãciunescu, C.M.: Cavitation erosion of sensitized UNS S31803 duplex stainless steels. J. Mater. Eng. Perform. 25, 2016–1939 (2018)

Mills, D.J., Knutsen, R.D.: An investigation of the tribological behaviour of a high-nitrogen CrMn austenitic stainless steel. Wear 215, 83–90 (1998)

Fu, W.T., Zheng, Y.Z., He, X.K.: Resistance of a high nitrogen austenitic steel to cavitation erosion. Wear 249, 788–791 (2001)

Zheng, Y.G., Luo, S.Z., Ke, W.: Effect of passivity on electrochemical corrosion behavior of alloys during cavitation in aqueous solutions. Wear 262, 1308–1314 (2007)

Wang, Z.B., Hu, H.X., Liu, C.B., Zheng, Y.G.: The effect of fluoride ions on the corrosion behavior of pure titanium in 0.05 M sulfuric acid. Electrochim. Acta 135, 526–535 (2014)

Li, Y., Xu, J.: Is niobium more corrosion-resistant than commercially pure titanium in fluoride-containing artificial saliva? Electrochim. Acta 233, 151–166 (2017)

Grajales, D.H.M., Ospina, C.M.G., Tschiptschin, A.P.: Mesoscale plasticity anisotropy at the earliest stages of cavitation-erosion damage of a high nitrogen austenitic stainless steel. Wear 267, 99–103 (2009)

Garzón, C.M., Dos Santos, J.F., Thomas, H., Tschiptschin, A.P.: Cavitation erosion resistance of a high temperature gas nitrided duplex stainless steel in substitute ocean water. Wear 259, 145–153 (2005)

Hoar, T.P., West, J.M.: Mechano-chemical anodic dissolution of austenitic stainless steel in hot chloride solution. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 268, 304–315 (1962)

Goudda, V.K., Al-Hashem, A.H., Abdullah, A.M., Riad, W.T.: Effect of ultrasonically induced cavitation on behaviour of nodular cast iron in sea water. Br. Corros. J. 26, 109–116 (1991)

Luo, S.Z., Li, M.C., Ke, W., Yao, Z.M., Zheng, Y.G.: Effect of cavitation on corrosion behavior of 20SiMn low-alloy steel in 3% sodium chloride solution. Corrosion 59, 597–605 (2003)

Robertson, I.M.: The effect of hydrogen on dislocation dynamics. Eng. Fract. Mech. 68, 671–692 (2001)

Delafosse, D., Magnin, T.: Hydrogen induced plasticity in stress corrosion cracking of engineering systems. Eng. Fract. Mech. 68, 693–729 (2001)

Acknowledgements

We would like to express our gratitude to the financial support of the National Natural Science Foundation of China (Nos. 51401092, 51131008, 51434004, U1435205, and 51304041) and Science and Technology Program of Jiangsu Province (BE2017143).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Qiao, Y., Tian, Z., Cai, X. et al. Cavitation Erosion Behaviors of a Nickel-Free High-Nitrogen Stainless Steel. Tribol Lett 67, 1 (2019). https://doi.org/10.1007/s11249-018-1118-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1118-7

Keywords

Profiles

- Yanxin Qiao View author profile