Abstract

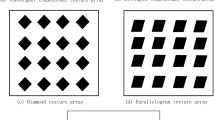

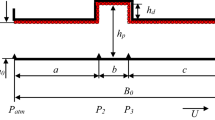

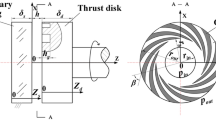

The transient behavior of cavitation phenomenon in textured thrust bearings with oil lubricant was experimentally investigated. During experiments, the cavitation phenomenon in different surface textures was observed directly with a high-speed camera. It is shown that cavitation shape and area change according to texture patterns. The bubbles within cavitation zones increase with running time in the beginning and gradually reach a steady state, meaning that a transient period is needed to achieve equilibrium. In addition, the bubble composition was analyzed under the temperature of 35 °C and pressure of 30 kPa. The results show that oil vaporization plays a minor role in the formation of bubbles.

Similar content being viewed by others

References

Dowson, D., Taylor, C.M.: Cavitation in bearings. Annu. Rev. Fluid Mech. 11, 35–65 (1979)

Hamrock, B.J., Jacobson, B.O.: High-speed motion picture camera experiments of cavitation in dynamically loaded journal bearings. J. Tribol. 105, 446–452 (1983)

Sun, D.C., Brewe, D.E.: A high speed photography study of cavitation in a dynamically loaded journal bearing. J. Tribol. 113, 287–294 (1990)

Sun, D.C., Brewe, D.E., Abel, P.B.: Simultaneous pressure measurement and high-speed photography study of cavitation in a dynamically loaded journal bearing. J. Tribol. 115, 88–95 (1994)

Etsion, I., Ludwig, L.P.: Observation of pressure variation in the cavitation region of submerged journal bearings. J. Tribol. 104, 157–163 (1981)

Groper, M., Etsion, I.: The effect of shear flow and dissolved gas diffusion on the cavitation in a submerged journal bearing. J. Tribol. 123, 494–500 (2001)

Groper, M., Etsion, I.: Reverse flow as a possible mechanism for cavitation pressure build-up in a submerged journal bearing. J. Tribol. 124, 320–326 (2002)

Braun, M.J., Hendricks, R.C.: An experimental investigation of the vaporous/gaseous cavity characteristics of an eccentric journal bearing. Tribol. Trans. 27, 1–14 (1982)

Someya, T.: On the development of negative pressure in oil film and the characteristics of journal bearing. Meccanica 38, 643–658 (2003)

Ausas, R., Ragot, P., Leiva, J., Jai, M., Bayada, G., Buscaglia, G.C.: The impact of the cavitation model in the analysis of microtextured lubricated journal bearings. J. Tribol. 129, 868–875 (2007)

Hamilton, D.B., Walowit, J.A., Allen, C.M.: A theory of lubrication by microirregularities. ASME Trans. J. Basic Eng. 88, 177–185 (1966)

Sahlin, F., Glavatskih, S.B., Almqvist, T., Larsson, R.: Two-dimensional CFD-analysis of micro-patterned surfaces in hydrodynamic lubrication. J. Tribol. 127, 96–102 (2005)

Wang, X.L., Kato, K., Adachi, K., Aizawa, K.: Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol. Int. 36, 189–197 (2003)

Yu, T.H., Sadeghi, F., Yu, T.H.: Groove effects on thrust washer lubrication. J. Tribol. 123, 295–304 (2000)

Wang, H.F., Yang, S.Y., Guo, F.: Modeling of a grooved parallel bearing with a mass-conserving cavitation algorithm. Tribol. Trans. 54, 227–236 (2011)

Dobrica, M.B., Fillon, M., Pascovici, M.D., Cicone, T.: Optimizing surface texture for hydrodynamic lubricated contacts using a mass-conserving numerical approach. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 224, 737–750 (2010)

Qiu, Y., Khonsari, M.M.: On the prediction of cavitation in dimples using a mass-conservative algorithm. J. Tribol. 131, 041702 (2009)

Qiu, Y., Khonsari, M.M.: Experimental investigation of tribological performance of laser textured stainless steel rings. Tribol. Int. 44, 635–644 (2011)

Zhang, J.Y., Meng, Y.G.: Direct observation of cavitation phenomenon and hydrodynamic lubrication analysis of textured surfaces. Tribol. Lett. 46, 147–158 (2012)

Cross, A.T., Sadeghi, F., Cao, L., Rateick Jr., R.G., Rowan, S.: Flow visualization in a pocketed thrust washer. Tribol. Trans. 55, 571–581 (2012)

Cross, A.T., Sadeghi, F., Rateick Jr., R.G., Rowan, S.: Hydrodynamic pressure generation in a pocketed thrust washer. Tribol. Trans. 56, 652–662 (2013)

Elrod, H.G.: A cavitation algorithm. J. Tribol. 103, 350–354 (1981)

Vijayaraghavan, D., Keith Jr., T.G.: Development and evaluation of a cavitation algorithm. Tribol. Trans. 32, 225–233 (1989)

Vijayaraghavan, D., Keith, T.G.: An efficient, robust, and time accurate numerical scheme applied to a cavitation algorithm. J. Tribol. 112, 44–51 (1990)

Vijayaraghavan, D., Keith, T.G.: Grid transformation and adaption techniques applied in the analysis of cavitated journal bearings. J. Tribol. 112, 52–59 (1990)

Payvar, P., Salant, R.F.: A computational method for cavitation in a wavy mechanical seal. J. Tribol. 114, 199–204 (1992)

Brizmer, V., Kligerman, Y., Etsion, I.: A laser surface textured parallel thrust bearing. Tribol. Trans. 46, 397–403 (2003)

Etsion, I., Halperin, G., Brizmer, V., Kligerman, Y.: Experimental investigation of laser surface textured parallel thrust bearings. Tribol. Lett. 17, 295–300 (2004)

Shen, C., Khonsari, M.M.: On the magnitude of cavitation pressure of steady-state lubrication. Tribol. Lett. 51, 153–160 (2013)

Qiu, Y., Khonsari, M.M.: Performance analysis of full-film textured surfaces with consideration of roughness effect. J. Tribol. 133, 307–314 (2011)

Hao, Z.R., Gu, C.W.: Numerical modeling for gaseous cavitation of oil film and non-equilibrium dissolution effects in thrust bearings. Tribol. Int. 78, 14–26 (2014)

Gherca, A.R., Maspeyrot, P., Hajjam, M., Fatu, A.: Influence of texture geometry on the hydrodynamic performances of parallel bearings. Tribol. Trans. 56, 321–332 (2013)

Yu, H.W., Wang, X.L., Zhou, F.: Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces. Tribol. Lett. 37, 123–130 (2010)

Acknowledgments

The authors would like to acknowledge the support of Shell Global Solutions (USA) as well as the NSFC with the Grant No. 51323006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bai, L., Meng, Y. & Zhang, V. Experimental Study on Transient Behavior of Cavitation Phenomenon in Textured Thrust Bearings. Tribol Lett 63, 27 (2016). https://doi.org/10.1007/s11249-016-0715-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0715-6