Abstract

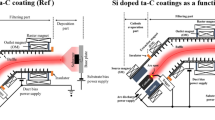

The effect of two different surface modification methods on the wear life of the coating of magnetic tape drive heads has been studied. In this research, the heads were coated with 10 nm tetrahedral amorphous carbon (ta-C) film using filtered cathodic vacuum arc (FCVA) technique. The surface of the heads was pretreated by bombarding with energetic carbon ions or by developing a Si–Al–C composite interlayer before deposition of the coating. The coated heads were tested at a real head/tape interface of a tape drive. Surface characterization and tribological behavior of the head coatings with and without surface modification has been studied by transmission electron microscopy (TEM), Auger electron spectroscopy (AES), and scanning electron microscopy (SEM). The results reveal that the ta-C coating without any surface modification is not durable and the coating fails due to delamination. Pre-treating the head surface with energetic carbon ions improves the durability of the coating, especially on the head read/write elements; however, the coating of the head ceramic substrate is still partially delaminated. The application of a Si–Al–C composite interlayer is shown to be able to solve the delamination problem effectively and increase the wear life of the coating up to six times in comparison with the sample pretreated with carbon ions. The formation of strong chemical bonds between the head surface and the overcoat is found to be an important factor in improving the durability of the ta-C head coating.

Similar content being viewed by others

References

Dee, R.H.: Magnetic tape for data storage: an enduring technology. Proc. IEEE 96(11), 1775–1785 (2008)

International Magnetic Tape Application and Systems Roadmap, Information Storage Industry Consortium (INSIC), USA (2011)

Wallace, R.L.: The reproduction of magnetically recorded signal. Bell Syst. Technol. J. 30, 1145–1173 (1951)

Thomson, T., Abelmann, L., Groenland, H.: Magnetic data storage: past present and future. In: Azzerboni, B., Asti, G., Pareti, L., Ghidini, M. (eds.) Magnetic nanostructures in modern technology, pp. 237–306. Springer, Netherlands (2008)

Spada, F.: Contribution of electrochemical processes to increased head-media spacing in tape drives, reported in INSIC TAPE Program Technical Reviews (www.insic.org/tape.htm). In. Boise, Idaho, USA, (2011), also abstract DT-06 of the 52 nm Annual MMM conference, Tampa, Florida November, 2007

Sourty, E., Sullivan, J.L., De Jong, L.A.M.: Pole tip recession in linear recording heads. IEEE Trans. Magn. 39(3 II), 1859–1861 (2003)

Bhushan, B., Patton, S.T., Sundaram, R., Dey, S.: Pole tip recession studies of hard carbon-coated thin-film tape heads. J. Appl. Phys. 79(8 PART 2B), 5916–5918 (1996)

Bhushan, B., Theunissen, G.S.A.M., Li, X.: Tribological studies of chromium oxide films for magnetic recording applications. Thin Solid Films 311(1–2), 67–80 (1997)

Sourty, E., Sullivan, J.L., Bijker, M.D.: Chromium oxide coatings applied to magnetic tape heads for improved wear resistance. Tribol. Int. 36(4–6), 389–396 (2003). doi:10.1016/s0301-679x(02)00214-1

Theunissen, G.S.A.M.: Wear coatings for magnetic thin film magnetic recording heads. Tribol. Int. 31(9), 519–523 (1998). doi:10.1016/s0301-679x(98)00062-0

Gupta, B.K., Bhushan, B.: Mechanical and tribological properties of hard carbon coatings for magnetic recording heads. Wear 190(1), 110–122 (1995)

Scott, W.W., Bhushan, B., Lakshmikumaran, A.V.: Ultrathin diamond-like carbon coatings used for reduction of pole tip recession in magnetic tape heads. J. Appl. Phys. 87(9), 6182–6184 (2000)

Robertson, J.: Ultrathin carbon coatings for magnetic storage technology. Thin Solid Films 383(1–2), 81–88 (2001)

Bhatia, C.S., Anders, S., Brown, I.G., Bobb, K., Hsiao, R., Bogy, D.B.: Ultra-thin overcoats for the head/disk interface tribology. J. Tribol. 120(4), 795–799 (1998). doi:10.1115/1.2833781

Pharr, G.M., Callahan, D.L., McAdams, S.D., Tsui, T.Y., Anders, S., Anders, A., III, J.W.A., Brown, I.G., Bhatia, C.S., Silva, S.R.P., Robertson, J.: Hardness, elastic modulus, and structure of very hard carbon films produced by cathodic-arc deposition with substrate pulse biasing. Appl. Phys. Lett. 68(6), 779–781 (1996)

Robertson, J.: Requirements of ultrathin carbon coatings for magnetic storage technology. Tribol. Int. 36(4–6), 405–415 (2003). doi:10.1016/s0301-679x(02)00216-5

Casiraghi, C., Ferrari, A.C., Ohr, R., Flewitt, A.J., Chu, D.P., Robertson, J.: Dynamic roughening of tetrahedral amorphous carbon. Phys. Rev. Lett. 91(22), 226104 (2003)

Casiraghi, C., Robertson, J., Ferrari, A.C.: Diamond-like carbon for data and beer storage. Mater. Today 10(1–2), 44–53 (2007)

Bhushan, B.: Chemical, mechanical and tribological characterization of ultra-thin and hard amorphous carbon coatings as thin as 3.5 nm: recent developments. Diam. Relat. Mater. 8(11), 1985–2015 (1999). doi:10.1016/s0925-9635(99)00158-2

Li, D.J., Guruz, M.U., Bhatia, C.S., Chung, Y.-W.: Ultrathin CNx overcoats for 1 Tb/in2 hard disk drive systems. Appl. Phys. Lett. 81(6), 1113–1115 (2002). doi:10.1063/1.1498866

Shum, P.W., Zhou, Z.F., Li, K.Y.: Tribological performance of amorphous carbon films prepared on steel substrates with carbon implantation pre-treatment. Wear 256(3–4), 362–373 (2004). doi:10.1016/s0043-1648(03)00441-1

Tong, H.H., Monteiro, O.R., Brown, I.G.: Effects of carbon ion pre-implantation on the mechanical properties of ta-C coatings on Ti-6Al-4V. Surf. Coat. Technol. 136(1–3), 211–216 (2001). doi:10.1016/s0257-8972(00)01058-6

Park, C.K., Chang, S.M., Uhm, H.S., Seo, S.H., Park, J.S.: XPS and XRR studies on microstructures and interfaces of DLC films deposited by FCVA method. Thin Solid Films 420–421, 235–240 (2002). doi:10.1016/s0040-6090(02)00750-2

Meyerson, B.S., Joshi, R.V., Rosenberg, R., Patel, V.V.: Silicon/carbon protection of metallic magnetic structures. US Patent 4647494

Komvopoulos, K., Zhang, H., Bhatia, C.S.: Systems and methods for surface modification by filtered cathodic vacuum arc. US Patent aplication 20100190036

Han, H., Ryan, F., McClure, M.: Ultra-thin tetrahedral amorphous carbon film as slider overcoat for high areal density magnetic recording. Surf. Coat. Technol. 120–121, 579–584 (1999). doi:10.1016/s0257-8972(99)00448-x

Rismani, E., Sinha, S.K., Tripathy, S., Yang, H., Bhatia, C.S.: Effect of pre-treatment of the substrate surface by energetic C+ ion bombardment on structure and nano-tribological characteristics of ultra-thin tetrahedral amorphous carbon (ta-C) protective coatings. J. Phys. D Appl. Phys. 44(11), 115502 (2011). doi:10.1088/0022-3727/44/11/115502

Rismani, E., Sinha, S. K., Yang, H., and Bhatia, C. S.: Effect of pre-treatment of Si interlayer by energetic C+ ions on the improved tribo-mechanical properties of magnetic head overcoat. J. Appl. Phys. (2012). doi:10.1063/1.3699058

Anders, A.: Cathodic arcs: from fractal spots to energetic condensation. Springer Science, New York (2008)

Carlson, T.A.: Photoelectron and Auger Spectroscopy. Plenum Press, New York (1975)

Hedberg, C.L.: Handbook of auger electron spectroscopy. Physical Electronics, Inc

Robertson, J.: Deposition mechanisms for promoting sp3 bonding in diamond-like carbon. Diam. Relat. Mater. 2(5–7), 984–989 (1993). doi:10.1016/0925-9635(93)90262-z

Catledge, S., Vaid, R., Diggins, P., Weimer, J., Koopman, M., Vohra, Y.: Improved adhesion of ultra-hard carbon films on cobalt–chromium orthopaedic implant alloy. J. Mater. Sci. Mater. Med. 22(2), 307–316 (2011). doi:10.1007/s10856-010-4207-1

Tang, Y., Li, Y.S., Zhang, C.Z., Wang, J., Yang, Q., Hirose, A.: Synthesis of cobalt/diamond-like carbon thin films by biased target ion beam deposition. Diam. Relat. Mater. 20(4), 538–541 (2011). doi:10.1016/j.diamond.2011.02.014

Correa, S.A., Marmitt, G.G., Bom, N.M., da Rosa, A.T., Stedile, F.C., Radtke, C., Soares, G.V., Baumvol, I.J.R., Krug, C., Gobbi, A.L.: Enhancement in interface robustness regarding thermal oxidation in nanostructured Al2O3 deposited on 4H–SiC. Appl. Phys. Lett. 95(5), 051913–051916 (2009). doi:10.1063/1.3195702

Klein, T.M., Niu, D., Epling, W.S., Li, W., Maher, D.M., Hobbs, C.C., Hegde, R.I., Baumvol, I.J.R., Parsons, G.N.: Evidence of aluminum silicate formation during chemical vapor deposition of amorphous Al2O3 thin films on Si(100). Appl. Phys. Lett. 75(25), 4001–4003 (1999). doi:10.1063/1.125519

Prabhakaran, V., Talke, F.E.: Wear and hardness of carbon overcoats on magnetic recording sliders. Wear 243(1–2), 18–24 (2000). doi:10.1016/s0043-1648(00)00392-6

Acknowledgments

This research was partly funded by the Information Storage Industry Consortium (INSIC) TAPE Program and the Singapore NRF under CRP Award No. NRF-CRP 4-2008-6. The authors thank Dr. Robert Raymond of Oracle America Inc. for providing the heads and Mr. Douglas Johnson from Imation Corp. for providing the SDS tape transport system.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rismani, E., Sinha, S.K., Yang, H. et al. Development of a ta-C Wear Resistant Coating with Composite Interlayer for Recording Heads of Magnetic Tape Drives. Tribol Lett 46, 221–232 (2012). https://doi.org/10.1007/s11249-012-9941-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-9941-8