Abstract

We report an experimental study of evaporation due to controlled infrared (IR) heating from above from an initially saturated confined porous medium consisting of nearly ‘mono-disperse’ particles which has been rarely used earlier. We have used three diagnostic tools simultaneously, evaporation rate measurements using a precision weighing balance, surface temperature measurements using IR imaging, and fluorescein dye mixed with water to visualize the drying front and the evaporation sites. IR images show that the first stage, so-called constant rate period (CRP), was maintained due to films of water reaching the top surface from the saturated region below. Gradually reducing evaporation rate in stage 1 is shown to be related to ‘shrinking evaporating patches’ on the top surface, clearly revealed as lower-temperature regions in the IR images. End of CRP coincides with disappearance of the low-temperature patches. We give end of CRP in terms of the average depth (Lcap) of the liquid level from the top surface at that time. Lcap and duration of CRP are strong functions of the porous medium bead size, transition to stage 2 happening earlier for coarser spheres. The obtained Lcap values deviated from the predictions of Lehmann et al. (Phys Rev E 77(5):056309, 2008) which we show is due to a small range of pore sizes in the current experiments. For both water and highly volatile n-pentane, we show that Lcap normalized by a length scale derived from gravity-surface tension force balance goes like Bo0.20, for Bo varying from 2.0E − 04 to 1.0E − 01; Bo is the Bond number. Fluorescein dye imaging shows a different view of the evaporation stages. During CRP, highly concentrated deposits of the fluorescein dye particles, orange in colour, are seen in the top few bead layers. These orange deposits represent the sites on the beads surfaces where the evaporation has taken place. Even with external heating, evaporation from such a porous medium is limited to a finite depth from the evaporating end, similar to the observation by Lehmann et al. (2008) for isothermal evaporation in Hele-Shaw cell.

Similar content being viewed by others

References

Aminzadeh, M., Or, D.: Temperature dynamics during nonisothermal evaporation from drying porous surfaces. Water Resour. Res. 49(11), 7339–7349 (2013)

Aminzadeh, M., Or, D.: Energy partitioning dynamics of drying terrestrial surfaces. J. Hydrol. 519, 1257–1270 (2014)

Aminzadeh, M., Or, D.: Pore-scale study of thermal fields during evaporation from drying porous surfaces. Int. J. Heat Mass Transf. 104, 1189–1201 (2017)

Assouline, S., Narkis, K., Or, D.: Evaporation from partially covered water surfaces. Water Resour. Res. (2010). https://doi.org/10.1029/2010WR009121

Assouline, S., Narkis, K., Gherabli, R., Lefort, P., Prat, M.: Analysis of the impact of surface layer properties on evaporation from porous systems using column experiments and modified definition of characteristic length. Water Resour. Res. 50(5), 3933–3955 (2014)

Bergstad, Mina, Or, Dani, Withers, PhilipJ, Shokri, Nima: The influence of NaCl concentration on salt precipitation in heterogeneous porous media. Water Resour. Res. 53(2), 1702–1712 (2017)

Brutsaert, W., Chen, D.: Desorption and the two stages of drying of natural tallgrass prairie. Water Resour. Res. 31(5), 1305–1313 (1995)

Campbell, R.E.: Evaporation from bare soil as affected by texture and temperature. Vol. 190, Rocky Mountain Forest and Range Experiment Station (1971)

Carman, P.C.: Fluid flow through granular beds. Transactions-Institution of Chemical Engineers 15, 150–166 (1937)

Carman, P.C.: Flow of Gases Through Porous Media. Academic Press, New York (1956)

Cejas, C.M., Castaing, J.-C., Hough, L., Frétigny, C., Dreyfus, R.: Experimental investigation of water distribution in a two-phase zone during gravity-dominated evaporation. Phys. Rev. E 96(6), 062908 (2017)

Chauvet, Fabien, Duru, Paul, Geoffroy, Sandrine, Prat, Marc: Three periods of drying of a single square capillary tube. Phys. Rev. Lett. 103(12), 124502 (2009)

Dashtian, H., Shokri, N., Sahimi, M.: Pore-network model of evaporation-induced salt precipitation in porous media: the effect of correlations and heterogeneity. Adv. Water Resour. 112, 59–71 (2018)

Fisher, E.A.: Some moisture relations of colloids. I. A comparative study of the rates of evaporation of water from wool, sand and clay. Proc. R. Soc. Lond. A 103(720), 139–161 (1923a)

Fisher, E.A.: Some moisture relations of colloids. II. Further observations on the evaporation of water from clay and wool. Proc. R. Soc. Lond. A 103(723), 664–675 (1923b)

Gardner, H.R., Hanks, R.J.: Effect of sample size and environmental conditions on evaporation of water from soils. USD A Conserv. Res. Rep. No. 9. 14 pp. (1966)

Geoffroy, S., Prat, M.: A review of drying theory and modelling approaches. In: Drying and Wetting of Building Materials and Components, pp. 145–173. Springer International Publishing (2014)

Hide, J.C.: Observations on factors influencing the evaporation of soil moisture. Soil Sci. Soc. Am. J. 18(3), 234–239 (1954)

Huinink, H.P., Pel, L., Michels, M.A.J., Prat, M.: Drying processes in temperature gradients–pore scale modelling. Eur. Phys. J. E. 9, 487–498 (2002)

Idso, S.B., Reginato, R.J., Jackson, R.D., Kimball, B.A., Nakayama, F.S.: The three stages of drying of a field soil. Soil Sci. Soc. Am. J. 38(5), 831–837 (1974)

Ishimwe, R., Abutaleb, K., Ahmed, F.: Applications of thermal imaging in agriculture—A review. Advances in Remote Sensing 3(03), 128 (2014)

Israelsen, O.W., West, F.L.R.: Water-holding capacity of irrigated soils. No. 183. Utah Agricultural College Experiment Station (1922)

Jackson, R.D., Kimball, B.A., Reginato, R.J., Nakayama, F.S.: Diurnal soil-water evaporation: time-depth-flux patterns. Soil Sci. Soc. Am. J. 37(4), 505–509 (1973)

Keen, B.A.: The evaporation of water from soil. J. Agric. Sci. 6(pt 4), 456–475 (1914)

Keita, E., Faure, P., Rodts, S., Coussot, P.: MRI evidence for a receding-front effect in drying porous media. Phys. Rev. E 87(6), 062303 (2013)

Keita, E., Koehler, S.A., Faure, P., Weitz, D.A., Coussot, P.: Drying kinetics driven by the shape of the air/water interface in a capillary channel. Eur. Phys. J. E 39(2), 23 (2016)

Kozeny, J.: Uber kapillare leitung der wasser in boden. R. Acad. Sci. Vienna Proc. Class I 136, 271–306 (1927)

Kuehni, S.M.S.S., Bou-Zeid, E., Webb, C., Shokri, N.: Roof cooling by direct evaporation from a porous layer. Energy Build. 127, 521–528 (2016)

Kumar, N., Arakeri, J.H.: Natural Convection Driven Evaporation from a water surface. Procedia IUTAM 15, 108–115 (2015)

Laurindo, J.B., Prat, M.: Numerical and experimental network study of evaporation in capillary porous media@ Phase distributions. Chem. Eng. Sci. 51(23), 5171–5185 (1996)

Laurindo, J.B., Prat, M.: Numerical and experimental network study of evaporation in capillary porous media. Drying rates. Chem. Eng. Sci. 53(12), 2257–2269 (1998)

Le Bray, Y., Prat, M.: Three-dimensional pore network simulation of drying in capillary porous media. Int. J. Heat Mass Transf. 42(22), 4207–4224 (1999)

Lehmann, P., Assouline, S., Or, D.: Characteristic lengths affecting evaporative drying of porous media. Phys. Rev. E 77(5), 056309 (2008)

Lemon, E.R.: The potentialities for decreasing soil moisture evaporation loss. Soil Sci. Soc. Am. J. 20(1), 120–125 (1956)

Lloyd, J.R., Moran, W.R.: Natural convection adjacent to horizontal surface of various planforms. J. Heat Transfer 96(4), 443–447 (1974)

Mitarai, N., Nori, F.: Wet granular materials. Adv. Phys. 55(1–2), 1–45 (2006)

Or, D., Lehmann, P., Shahraeeni, E., Shokri, N.: Advances in soil evaporation physics—a review. Vadose Zone J. 12(4), 16 (2013)

Prat, M.: Percolation model of drying under isothermal conditions in porous media. Int. J. Multiph. Flow 19(4), 691–704 (1993)

Prat, M.: Recent advances in pore-scale models for drying of porous media. Chem. Eng. J. 86(1), 153–164 (2002)

Qiu, G.Y., Shi, P., Wang, L.: Theoretical analysis of a remotely measurable soil evaporation transfer coefficient. Remote Sens. Environ. 101(3), 390–398 (2006)

Schlünder, E.U.: On the mechanism of the constant drying rate period and its relevance to diffusion controlled catalytic gas phase reactions. Chem. Eng. Sci. 43(10), 2685–2688 (1988)

Schlünder, E.U.: Drying of porous material during the constant and the falling rate period: a critical review of existing hypotheses. Drying Technol. 22(6), 1517–1532 (2004)

Shahraeeni, E., Lehmann, P., Or, D.: Coupling of evaporative fluxes from drying porous surfaces with air boundary layer: Characteristics of evaporation from discrete pores. Water Resour. Res. (2012). https://doi.org/10.1029/2012WR011857

Shaw, T.M.: Drying as an immiscible displacement process with fluid counterflow. Phys. Rev. Lett. 59(15), 1671 (1987)

Sherwood, T.K.: The drying of solids—II. Ind. Eng. Chem. 21(10), 976–980 (1929)

Shokri-Kuehni, S., Vetter, T., Webb, C., Shokri, N.: New insights into saline water evaporation from porous media: Complex interaction between evaporation rates, precipitation and surface temperature. Geophys. Res. Lett. 44, 5504–5510 (2017a). https://doi.org/10.1002/2017GL073337

Shokri-Kuehni, S.M.S., Rad, M.N., Webb, C., Shokri, N.: Impact of type of salt and ambient conditions on saline water evaporation from porous media. Adv. Water Resour. 105, 154–161 (2017b)

Shokri, N., Lehmann, P., Vontobel, P., Or, D.: Drying front and water content dynamics during evaporation from sand delineated by neutron radiography. Water Resour. Res. (2008). https://doi.org/10.1029/2007WR006385

Shokri, N., Lehmann, P., Or, D.: Critical evaluation of enhancement factors for vapor transport through unsaturated porous media. Water Resour. Res. (2009). https://doi.org/10.1029/2009WR007769

Shokri, N., Or, D.: What determines drying rates at the onset of diffusion controlled stage‐2 evaporation from porous media? Water Resour. Res. (2011). https://doi.org/10.1029/2010WR010284

Suzuki, M., Maeda, S.: On the mechanism of drying of granular beds. J. Chem. Eng. Jpn 1(1), 26–31 (1968)

Thiery, J., Rodts, S., Weitz, D.A., Coussot, P.: Drying regimes in homogeneous porous media from macro-to nanoscale. Physical Review Fluids 2(7), 074201 (2017)

Van Brakel, J.: In: Mujumdar, A.S. (ed.) Advances in Drying, vol. 1, p. 217. Hemisphere, New York (1980)

Veihmeyer, F.J., Hendrickson, A.H.: The moisture equivalent as a measure of the field capacity of soils. Soil Sci. 32(3), 181–194 (1931)

Yiotis, A.G., Boudouvis, A.G., Stubos, A.K., Tsimpanogiannis, I.N., Yortsos, Y.C.: Effect of liquid films on the drying of porous media. AIChE J. 50(11), 2721–2737 (2004)

Yiotis, A.G., Salin, D., Tajer, E.S., Yortsos, Y.C.: Analytical solutions of drying in porous media for gravity-stabilized fronts. Phys. Rev. E 85(4), 046308 (2012a)

Yiotis, A.G., Salin, D., Tajer, E.S., Yortsos, Y.C.: Drying in porous media with gravity-stabilized fronts: experimental results. Phys. Rev. E 86(2), 026310 (2012b)

Yuan, C., Tingwu, L., Lili, M., Han, L., Yang, W.: Soil surface evaporation processes under mulches of different sized gravel. Catena 78(2), 117–121 (2009)

Acknowledgements

We thank Robert Bosch Centre for Cyber Physical Systems (RBCCPS/ME/JHA/PC 0013), Indian Institute of Science, for funding the work. We appreciate help of Prof. M. S. Bobji (Department of Mechanical Engineering, IISc Bangalore) and Prof. K. R. Sreenivas (JNCASR, Bangalore) during the analysis.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Preparing the Sample in Order to Get a Fixed Porosity

Protocol followed while preparing a porous media is as follows:-

-

1.

A cylindrical glass beaker or acrylic container is chosen as required. Deionized (DI) water was used in all the experiments.

-

2.

Small amount (5 mm) of water was poured in the beaker first, and spheres were dropped slowly in the beaker.

-

3.

The beaker was shaken well manually to ensure the flatness of the spheres top surface. In case water still remains on top of the spheres, some more spheres were dropped and the container was again shaken well. This was repeated until the spheres top surfaces became flat and got completely wet.

-

4.

Same procedure was repeated to get a desired height of the porous media.

-

5.

Extra water, which remained after reaching a desired height of porous column, was taken out by tissue papers in order to accurately get the amount of water used in the porous media. This gives us experimental volumetric porosity of the porous media.

-

6.

Once a saturated porous sample was created, it is then ready to be experimented on.

-

7.

In a few cases, extra 2–3 mm of water was put on top of the porous surface to get the value of potential evaporation.

Appendix B: Assessment of Two-Capillary model by Lehmann et al. (2008)

The characteristic capillary length (Lc) defined by Lehmann et al. (2008), for the two differently sized hydraulically connected capillaries, is:

For better understanding of these length scales, refer to Lehmann et al. (2008). Note that Lc was defined as the distance of the meniscus in the larger capillary from the top open end (Fig. 12a) just before the meniscus in the smaller capillary starts leaving the top. The equivalent capillary film length (Fig. 12b) for this simplistic model, as defined previously, can be given as:

a Conceptual two-capillary model of Lehmann et al. (2008) and b definition of an equivalent capillary film length, L eqcap (as used in the present study), in relation to Lc for the two-capillary model. Note that the relation (Lc > L eqcap ) is always satisfied in a porous medium

More relevant to the present discussion are the non-dimensional numbers, i.e. capillary (Ca) and Bond (Bo) numbers and Lgrav. They were defined, in Lehmann et al. (2008), as:

where μ is the dynamic viscosity of the liquid, e0 is the evaporation rate, r1 and r2 are the smaller and larger capillary radii, respectively, and κ is the permeability of the porous medium. In a porous medium, r1 and r2 need to be estimated from the experiments through water retention (capillary head vs saturation) curve for a given particle size range and the air entry value (Lehmann et al. 2008). For the two-capillary model, r1 and r2 (radius of the voids) can be defined in terms of the respective particle sizes as follows:

For example, in the case of experiment with 0.10–0.16-mm-diameter GB, r1 = (0.10/6) mm and r2 = (0.16/6) mm, respectively.

Since particle Reynolds number is low, permeability (κ) of the porous medium (water case) can be obtained using the Kozeny–Carman equation (Carman 1937, 1956; Kozeny 1927) which is about 1.45E − 11 m2 and 6.50E − 09 m2 for the smallest (0.10–0.16 mm) and the largest (2.50–3.00 mm) beads size. Corresponding to these values of κ, the ratio (Ca/Bo), calculated from Eq. (B2), is nearly 1.60E − 03 and 3.60E − 06, respectively, for the smallest and largest bead sizes. Evaporation rate of 20 mm/day has been used for estimating the non-dimensional numbers. We see that the ratio (Ca/Bo) is very small compared to 1 and thus \( L_{\text{c}} \cong L_{\text{grav}} \). Note that for isothermal evaporation cases (evaporation rate of about 2–3 mm/day) the ratio (Ca/Bo) will further decrease. Note that for evaporation rates more than 1000 mm/day this ratio cannot be neglected. These evaporation rates are typically achieved in heat pipes and thus viscous forces are critical in determining Lc. Using Eq. (13), L eqcap is estimated, from the two-capillary model, and is tabulated in Table 3, column 4 for water and column 8 for n-pentane, respectively. The disagreement between the two (present vs the two-capillary model) lengths is very large which forces us to conclude that the two-capillary model is not able to predict the length scales properly in mono-disperse cases. Note that for 0.10–0.16-mm-diameter GB and 0.30–0.50 sand cases the two-capillary model predicted higher values, similar to the current experimental observations; particle size variation in these two cases is significant.

Appendix C: Fluorescein Dye Images for Large Containers: Capillary-Gravity Regime

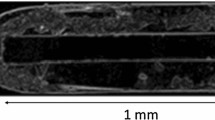

Figure 13 shows images captured at the beginning (a,b)) and end (c,d) of the experiment for an experiment with larger (0.70–0.85 mm diameter) glass beads placed in a cylindrical glass container. At the end of the experiment, (Fig. 13c) shows the deposited orange fluorescein dye particles distributed throughout the top surface, as was the case with the smaller beads. The side view (Fig. 13d) shows three distinct layers: (a) orange at the top, indicating evaporation from the glass beads surfaces there, (b) a wet green layer at the bottom, and (c) a white layer between these two, which is drained of water. The top layer is completely dry region, while the bottom layer is fully saturated with water. The mid-layer is white (colour of the glass beads) which shows that these locations were used only for drainage by the capillary film, and probably contains some water near the contact points of the beads, but there is no continuous film. The three layers indicate the true transition from CRP to FRP.

Images showing the condition before and after the experiment containing 0.70–0.85 mm GB, with fluorescein dye added to the water. a, b show the top and side views of the porous media, respectively, at the start of the experiment. Fluorescein in solution makes the porous medium appear green. c, d show the top and side views of the porous medium, respectively, at the end of the experiment, much after the transition had happened. Orange represents the deposited fluorescein particles regions, white represents water drained glass beads, and green (nearly 26 mm in height) represents the completely wet region. Whitish green colour represents the field capacity (FC) type of situation where solid, liquid, and gas coexist together. Height of the porous column was nearly 86 mm. The mass of water at saturation, transition, and at the end was nearly 95, 60, and 37 g, respectively. Porosity of the porous medium was nearly 35.4%. Heat flux received by the top surface of the porous medium ~ 1000 W/m2

Appendix D: Experiments with n-Pentane as the Evaporating Fluid

We carried out separate set of laboratory experiments on evaporating porous media with n-pentane as the evaporating fluid. The density and surface tension of n-pentane is 0.626 g/cc and 16 mN/m, respectively, at a room temperature of 25 °C. The respective values for water at the room temperature are 1 g/cc and 72 mN/m. The samples (mixture of glass beads and n-pentane in the cylindrical vessel) were prepared following the protocol given in “Appendix A”. Evaporation of n-pentane from different porous media was studied in the same environment as that of water viz. heating from above using the IR heater. The maximum evaporation rate in these experiments was found to be nearly 400 mm/day, as opposed to 20 mm/day for water case, for a heat input of 1000 W/m2 and the corresponding pentane vapours velocity is nearly 2 mm/s. The temperature of the ‘wet’ patch on the surface of the porous media in these experiments was between 12 and 20 °C in the first stage of evaporation and was 4–5 °C lower than the ‘dry’ patch. It should be noted that these values of temperatures are lower than the ambient temperature of approximately 24 °C. The porous medium in these experiments thus received heat energy not only from the external IR heater but also some from the ambient in the form of radiation and convection. Duration of CRP with n-pentane was found to be significantly lower compared to with water.

Similar wet and dry patch characteristics (third column) were observed (using a thermal camera) with n-pentane as the evaporating fluid as seen in Fig. 14. The optical images captured immediately at the end the experiment (fourth column) clearly showed the presence of a fully saturated region away from the top surface which predicts the true capillary film length in all the cases.

Thermal images taken at the beginning (first column) of the experiment and near the transition (second column) for different glass bead sizes with n-pentane as the evaporating liquid. Third column shows the condition at the end of the experiment. In all cases, a fully saturated porous media is seen clearly at the bottom, indicating true capillary film length. Heat flux received by the top surface in all cases was ~ 1000 W/m2

Rights and permissions

About this article

Cite this article

Kumar, N., Arakeri, J.H. Evaporation From Confined Porous Media Due to Controlled IR Heating From Above. Transp Porous Med 125, 311–340 (2018). https://doi.org/10.1007/s11242-018-1120-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-018-1120-4