Abstract

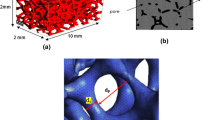

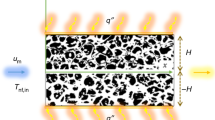

Simple, yet accurate representation of cell structure is essential when conducting a multidimensional thermo-fluid simulation on porous medium in microscopic scale. Presented in this paper is a study of the fluid dynamic simulation of the nickel metal foam’s unit cell domain using idealized cell structure. Commercially available multi-physics package, COMSOL, was utilized to conduct numerical simulation. Simplified methodology to create an idealized cell structure of metal foam is presented, and simulation results on pressure drop are discussed. Nonlinear solver in COMSOL was utilized to solve the unidirectional pressure drop and permeability across the cell structure. Obtained results showed confirmed agreement to the data obtained from the experiment and previous researchers, verifying the practicality and applicability of the proposed unit cell structure.

Similar content being viewed by others

References

Arisetty, S., Prasad, A.K., Advani, S.G.: Metal foams as flow field and gas diffusion layer in direct methanol fuel cells. J. Power Source 165, 49–57 (2007)

Bagci, O., Dukhan, N., Kavurmacioglu, L.A.: Forced-convection measurements in the fully developed and exit regions of open-cell metal foam. Transp. Porous Media 109, 49–57 (2015)

Banhart, J.: Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 46, 559–632 (2001)

Bhattacharya, A., Calmidi, A.A., Mahajan, R.L.: Thermo physical properties of high porosity metal foams. Int. J. Heat Mass Transf. 45, 1017–1031 (2002)

Bonnet, J.P., Topin, F., Tadrist, L.: Flow laws in metal foams: compressibility and pore size effects. Transp. Porous Med. 73, 233–254 (2008)

Boomsma, K., Poulikakos, D.: The effects of compression and pore size variations on the liquid flow characteristics in metal foams. J. Fluids Eng. 124, 263–272 (2002)

Chandan, A., Rees, N.V., Steinberger-Wilckens, R., Self, V., Richmond, J.: Improving the design of gas diffusion layer for intermediate temperature polymer electrolyte fuel cells using a sensitivity analysis: a Multiphysics approach. Int. J. Hydrogen Energy 40, 16745–16759 (2015)

Despois, J.F., Mortensen, A.: Permeability of open-pore microcellular materials. Acta Mater. 53, 1381–1388 (2005)

Du Plessis, J.P.: Pressure drop prediction for flow through high porosity metallic foams. Chem. Eng. Sci. 49, 3545–3553 (1994)

Dukhan, N., Picon-Feliciano, R., Alvarez-Hernandez, A.R.: Air flow through compressed and uncompressed aluminum foam: measurements and correlations. J. Fluids Eng. 128, 1004–1012 (2006)

Edouard, D., Lacroix, M., Pham, C., Mbodji, M., Pham-Huu, C.: Experimental measurements and multiphase flow models in solid SiC foam beds. AIChE J. 54, 2823–2832 (2008)

Forchheimer, P.: Wasserbewegung durch boden. Z. Ver. Deutsch. Ing. 45, 1782–1788 (1901)

Fourie, J.G., Du Plessis, J.P.: Pressure drop modelling in cellular metallic foams. Chem. Eng. Sci. 57, 2781–2789 (2002)

Hooman, K., Dukhan, N.: A theoretical model with experimental verification to predict hydrodynamics of foams. Transp. Porous Med. 100, 393–406 (2013)

Hwang, J.J., Hwang, G.J., Yeh, R.H., Chao, C. H.: Measurement of interstitial convective heat transfer and frictional drag for flow across metal foams. Trans. ASME 124 (2002)

Khayargoli P., Loya V., Lefebvre L.-P. Medraj M.: The impact of microstructure on the permeability of metal foams. In: Proceedings of CSME Forum, pp. 220-228. London, Canada (2004)

Krishnan, S., Murthy, J.Y., Garimella, S.V.: Direct simulation of transport in open-cell metal foam. ASME J. Heat Transf. 128, 793–799 (2006)

Kumar, A., Reddy, R.G.: Modeling of polymer electrolyte membrane fuel cell with metal foam in the flow-field of the bipolar/end plates. J. Power Sources 114, 54–62 (2002)

Lage, J.L., Antohe, B.V.: Darcy’s experiments and the deviation to nonlinear flow regime. J. Fluids Eng. 122, 619–625 (2000)

Lucci, F., Torre, A.D., von Rickenbach, J., Montenegro, G., Poulikakos, D., Eggenschwiler, P.D.: Performance of randomized Kelvin cell structures as catalytic substrates: mass-transfer based analysis. Chem. Eng. Sci. 112, 143–151 (2014)

Madani, B., Topin, F., Rigollet, F., Tadrist, L.: Flow laws in metallic foams: experimental determination of inertial and viscous contribution. J. Porous Media 10, 51–70 (2007)

Miwa, S., Revankar, S.T.: Hydrodynamic characterization of nickel metal foam, part 1: single-phase permeability. Transp. Porous Media 80, 269–279 (2009)

Miwa, S., Revankar, S.T.: Hydrodynamic characterization of nickel metal foam, part 2: effects of pore structure and permeability. Transp. Porous Media 89, 323–336 (2011)

Moreira, E.A., Innocentini, M.D.M., Coury, J.R.: Permeability of ceramic foams to compressible and incompressible flow. J. Eur. Ceram. Soc. 24, 3209–3218 (2004)

Oppenheimer, S.M., Dunand, D.C.: Finite element modeling of creep deformation in cellular metals. Acta Mater. 55, 3825–3834 (2007)

Richardson, J.T., Remue, D., Peng, Y.: Properties of ceramic foam catalyst supports: pressure drop. Appl. Catal. 204, 19–32 (2000)

Sobieski, W., Zhang, Q., Liu, C.: Predicting tortuosity for airflow through porous beds consisting of randomly packed spherical particles. Transp. Porous Media 93, 431–451 (2012)

Stemmet, C.P., van der Schaaf, M.M.J., Kuster, B.F.M., Schouten, J.C.: Hydrodynamics of gas-liquid counter-current flow in solid foam packings. Chem. Eng. Sci. 60, 6422–6429 (2005)

Vafai, K., Tien, C.L.: Boundary and inertia effects on convective mass transfer in porous media. Int. J. Heat Mass Transf. 25, 1183–1190 (1980)

Walter, J., Zurawski, A., Montgomery, D., Thornburg, M., Revankar, S.T.: Sodium borohydride hydrolysis kinetics comparison for nickel, cobalt, and ruthenium boride catalysts. J. Power Sources 179, 335–339 (2008)

Zhao, R., Zhang, S., Liu, J., Gu, J.: A review of thermal performance improving methods of lithium ion battery: electrode modification and thermal management system. J. Power Sources 299, 557–577 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miwa, S., Kane, C. & Revankar, S.T. Microscopic Fluid Dynamic Simulation of the Metal Foam Using Idealized Cell Structure. Transp Porous Med 115, 35–51 (2016). https://doi.org/10.1007/s11242-016-0750-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-016-0750-7